Ke Eng e Hot Forging

Ho qhekella ho chesang le ho batang ke mekhoa e 'meli e fapaneng ea ho etsa tšepe e fanang ka liphello tse tšoanang. Moetsi o tla sheba mekhoa e mengata pele a khetha hore na ke mofuta ofe oa forging o molemo ka ho fetisisa bakeng sa kopo e itseng.

Ts'ebetso ea Hot Forging process (Hape e bitsoa Hot Forming)

Ho chesoa ho chesang ke mokhoa oo thepa e lokelang ho futhumatsoa ka eona ho mocheso o phahameng ho thehoa, ke kamoo lebitso "hot forging" le tlang kateng. Karolelano ea lithempereichara tse hlokahalang bakeng sa ho fereka ho chesang ke:

Ho fihla ho likhato tse 1150 tsa Celsius bakeng sa tšepe

360 ho isa ho 520 likhato tsa Celsius bakeng sa Al-Alloys

700 ho isa ho 800 likhato tsa Celsius bakeng sa Cu-Alloys

Ho futhumatsa thepa nakong ea ho fereka ho chesang ho phahamisa mocheso ka holim'a ntlha ea recrystallization ea tšepe. Mocheso o feteletseng oa hlokahala ho qoba ho thatafala ha tšepe nakong ea deformation. Mofuta oa mofuta o chesang o bitsoang isothermal forging o thusa ho thibela oxidation ea litšepe tse itseng, joalo ka li-superalloys. Ha ho etsoa sepakapaka sa isothermal, mokhoa ona o etsahala sebakeng se laoloang haholo, se tšoanang le sa vacuum.

Litlhahiso tse chesang tsa ho qapa

Hangata bahlahisi ba khetha forging e chesang bakeng sa tlhahiso ea likarolo tse nang le tšusumetso e kholo lebaleng la tekheniki. Hot forging e boetse e kgothaletswa bakeng sa deformation ea tšepe e nang le sebopeho se phahameng karo-karolelano. Lintlha tse ling tse mabapi le ho ferekana ha mocheso li kenyelletsa:

1. Ho hlahisa likarolo tse sa tšoaneng

2. Ho nepahala ho tlase ho isa bohareng

3. Thekiso ea Sekala

4. Khatello e tlase kapa ho se be thata ha mosebetsi

5. Sebopeho sa lijo-thollo se homogenized

6. Keketseho ea ductility

7. Ho felisoa ha ho se lumellane ha lik'hemik'hale

Litšitiso tse ka bang teng tsa ho forging tse chesang

Mamello e fokolang e nepahetseng

Ho phunya ho ka khonehang ha thepa nakong ea ho pholisa

Sebopeho se fapaneng sa lijo-thollo tsa tšepe

Lintho tse ka etsahalang pakeng tsa sepakapaka se potolohileng le tšepe

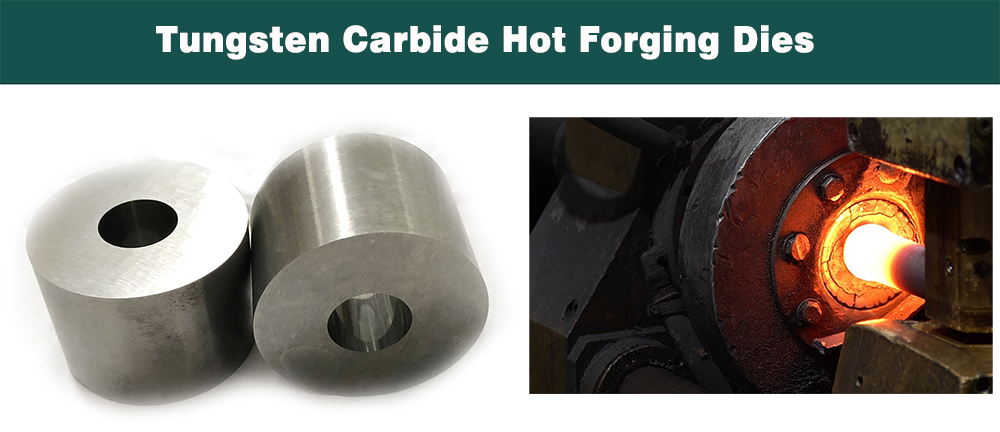

Zhuzhou Better Tungsten Carbide Company ke mofani oa tungsten carbide ka lilemo tse fetang 15, re fana ka lithupa tsa tungsten carbide, li-carbide strips, carbide dies, li-buttons tsa merafo ea tungsten carbide, joalo-joalo. Lihlahisoa tse ngata tsa carbide li sebelisoa boemong bo hlokang ts'ebetso e phahameng le botsitso bo phahameng esita le mochesong o phahameng. Har'a lihlahisoa tsohle, li-tungsten carbide die nibs li tla ba tse batang kapa tse chesang ka ho fetisisa qetellong ea bareki ho li etsa ka baki ho eketsa bophelo ba molemo ba sesebelisoa. Hot forging ke mokhoa oa bohlokoa oa ho kopanya li-carbide die nibs le baki ea tšepe ka sesebelisoa. Tlhokahalo efe kapa efe ea carbide forging dies, carbide drawing die blanks, amohela ikopanye le rona.

#tungstencarbide #carbideblank #carbidedie #hotforging #procurement