Hobaneng ha Melamu ea Rōna ea Carbide e Fumana Thoriso ho Bareki ba Rona?

Hobaneng ha Melamu ea Rōna ea Carbide e Fumana Thoriso ho Bareki ba Rona?

1. Phofo e Khabane.

Re sebelisa phofo ea 100% ea moroetsana bakeng sa lithupa tsa carbide bakeng sa limaraka tsohle tsa rona tse tloaelehileng bakeng sa tlhahiso ea lithupa tsa carbide.

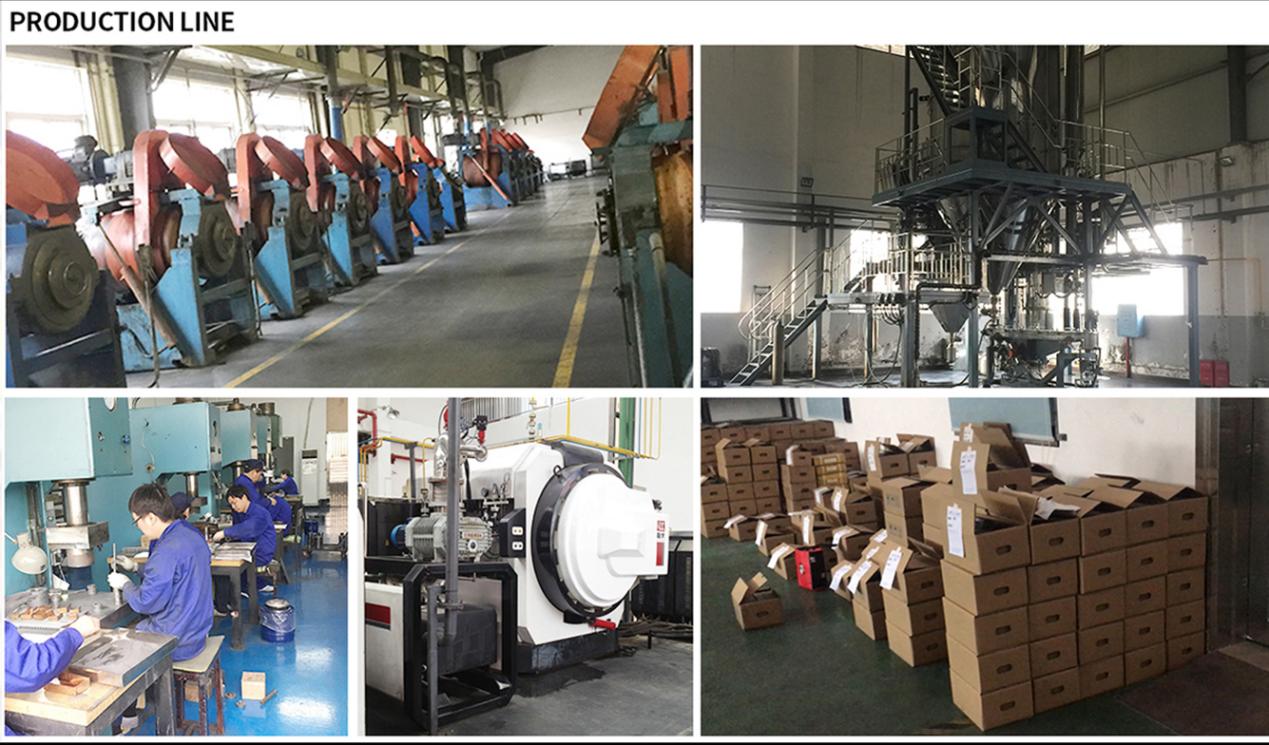

2. Lisebelisoa tse tsoetseng pele tsa tlhahiso

Tora ea ho fafatsa

The spray drying tower e sebelisoa haholo-holo ho omisa motsoako oa carbide e samente, 'me kaha e le ka mokhoa oa spray, likaroloana tsa alloy li tšoana haholoanyane.

HIP Sintering

Lisebelisoa tse tsoetseng pele tsa HIP tse laoloang ke k'homphieutha tse tsoang Jeremane li sebelisoa ho fana ka khatello e eketsehileng nakong ea ts'ebetso ea sintering e le ho fumana sebopeho se teteaneng.

Teko ea boima ba tungsten carbide

Carbide e entsoeng ka samente ke tšepe e ka bonahatsang phapang ea thepa ea mochine likarolong tsa lik'hemik'hale, metsoako ea lisele le mekhoa ea ho phekola mocheso. Ka hona, teko ea boima e sebelisoa haholo ho hlahloba thepa ea carbide, e ka laolang ho nepahala ha mokhoa oa ho phekola mocheso le lipatlisiso tsa lisebelisoa tse ncha. Ho lemoha boima ba tungsten carbide haholo-holo ho sebelisa Vickers hardness tester ho lekola boleng ba HRA ba thatafala. Teko e na le sebopeho se matla le ho ikamahanya le maemo a sekhechana sa teko ka katleho e phahameng.

3. Tlhahiso e potlakileng

Mekhoa e meraro e fapaneng ea compaction, ho kenyelletsa extrusion, mochini oa khatiso oa othomathike, le mochini oa khatiso o batang oa isostatic, o sebelisoa bakeng sa katleho e phahameng ea tlhahiso ea melamu ea carbide.

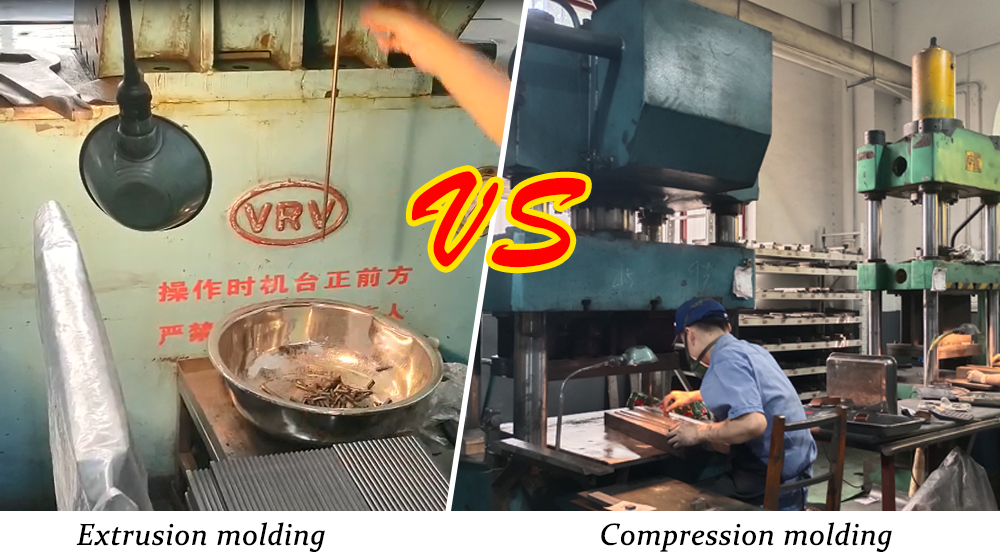

Extrusion

Extrusion ke mokhoa o tsebahalang haholo oa ho hlahisa lithupa tsa carbide. Ke mokhoa o sebetsang haholo oa ho etsa lithupa tse telele tsa carbide tse kang 330mm, 310mm le 500mm, joalo-joalo. Leha ho le joalo, mokhoa oa eona oa ho omisa nako ke bofokoli boo re lokelang ho bo ela hloko.

Tobetsa ka ho iketsa

Ho hatella ka mokhoa o itekanetseng ke mokhoa o atlehang ka ho fetisisa oa ho hatisa boholo bo khutšoanyane joaloka 6 * 50,10 * 75,16 * 100, joalo-joalo E ka boloka litšenyehelo ho tloha ho khaola lithupa tsa carbide 'me ha e hloke nako ea ho omella. Kahoo nako ea ho etella pele e potlakile ho feta extrusion. Leha ho le joalo, lithupa tse telele li ke ke tsa etsoa ka mokhoa ona.

Dry-bag isostatic tobetsa

Dry-bag isostatic pressing ke theknoloji ea morao-rao ea ho etsa lithupa tsa carbide. E ka hlahisa mekoallo e telele joalo ka 400mm mme ha e hloke boka e le ntho ea ho bopa. Ho feta moo, ha e hloke nako ea ho omella. Ena ke khetho e ntle ka ho fetisisa ha o etsa li-diameter tse kholo ho feta 16mm.

4. Sehlopha sa litsebi

Khamphani ea rona e ile ea bokella basebetsi ba hloahloa sebakeng sa ho rala, ho hlahisa le ho bapatsa. Basebetsi ba rona ba koetlisitsoe hantle ebile ba na le boiphihlelo. Sehlopha sa rona sea tšepahala, se na le tšepo, sea tšepahala, 'me se thabela ho fana ka tharollo bakeng sa bareki le ho theha boleng.

Zzbetter o na le GB/T19001-2016 / ISO9001: setifikeiti sa 2015, se nang le lisebelisoa tse tsoetseng pele, lisebelisoa tsa liteko le basebetsi ba hloahloa. Re ka tieo tsoela ISO9001: 2015 tlhoko ea ho netefatsa boleng.

Haeba u thahasella li-rod tsa tungsten carbide 'me u batla boitsebiso bo eketsehileng le lintlha tse ling, u ka RE THUTA ka mohala kapa ka poso ka ho le letšehali, kapa U RE THUSE MAIL botlaaseng ba leqephe.