Hobaneng le Joang ho Weld Carbide Grits ka Sanding Shaping Carving Wheel?

Hobaneng le Joang ho Weld Carbide Grits ka Sanding Shaping Carving Wheel?

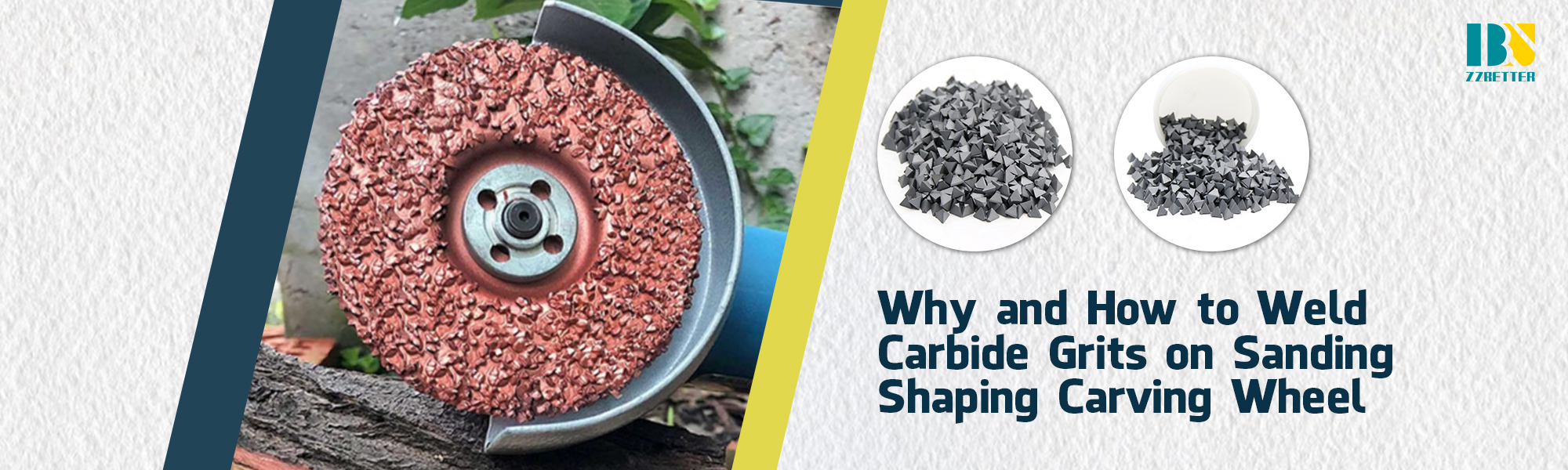

Ho cheselletsa litšepe tsa carbide holim'a lebili la sanding, sebopeho, kapa ho betla ho fana ka melemo e itseng. Carbide ke thepa e thata le e tšoarellang, e etsang hore e tšoanelehe bakeng sa lisebelisoa tsa abrasive. Ha litšepe tsa carbide li cheselletsoa lebiling, li etsa hore ho be le sebaka se makukuno se khonang ho seha, ho sila kapa ho bopa lintho tse sa tšoaneng tse kang lehong, tšepe kapa lejoe.

Li-grits tse cheselitsoeng tsa carbide li fana ka ts'ebetso e ntlafetseng ea ho itšeha le ho phela nako e telele ha li bapisoa le mabili a tloaelehileng a abrasive. Li khona ho mamella mocheso o phahameng 'me ha li na tšekamelo ea ho khathala kapele. Sena se etsa hore li sebetse hantle bakeng sa mesebetsi e hlokang ho tlosoa ha thepa e boima kapa tšebeliso ea nako e telele.

Mehato e akaretsang ea ho cheselletsa grits ea carbide holim'a lebili ke ena:

1. Khetha lebili le nepahetseng: Khetha lebili le loketseng sesebelisoa le lisebelisoa tseo u tla beng u sebetsa ka tsona. Nahana ka lintlha tse kang boholo ba lebili, lebelo la lebelo, le ho lumellana le grits ea carbide.

2. Lokisetsa lebili: Hloekisa bokaholimo ba lebili ka botlalo ho tlosa litšila leha e le life, maloanlahla kapa litšila tsa khale. Mohato ona o tiisa ho khomarela hantle pakeng tsa grits ea carbide le lebili.

3. Sebelisa lisebelisoa tsa ho tjheseletsa: Ho itšetlehile ka mokhoa o khethehileng oa ho tjheseletsa o sebelisitsoeng, ho ka 'na ha hlokahala hore u sebelise thepa ea ho cheselletsa kapa ajente holim'a lebili. Boitsebiso bona bo sebetsa e le mokhoa oa ho kopanya grits ea carbide lebiling.

4. Beha grits ea carbide: Beha ka hloko grits ea carbide holim'a lebili. Li-grits li lokela ho aroloa ka ho lekana le ho hlophisoa ka mokhoa o lakatsehang kapa tlhophiso.

5. Phekolo ea mocheso: Kenya mocheso lebiling ho kenya lisebelisoa tsa welding le ho nolofatsa mokhoa oa ho kopanya. Mocheso o khethehileng le nako ea phekolo ea mocheso e tla itšetleha ka mokhoa oa ho tjheseletsa le lisebelisoa tse sebelisoang.

6. Lumella ho phola le ho hlahloba: Hang ha ts'ebetso ea ho cheselletsa e felile, lumella lebili hore le phole. Lekola maqhama pakeng tsa grits ea carbide le lebili ho netefatsa hore e matla ebile e bolokehile. Li-grits leha e le life tse hlephileng kapa tse sa amaneng hantle li lokela ho lokisoa kapa ho nkeloa sebaka.

Ka kopo hlokomela hore mokhoa o nepahetseng oa ho tjheseletsa le lisebelisoa li ka fapana ho latela lisebelisoa le ts'ebeliso e itseng. Ho bohlokoa ho latela melaoana e nepahetseng ea polokeho le litataiso tsa moetsi nakong ea ts'ebetso ea welding ho netefatsa maqhama a atlehileng le a ts'epahalang lipakeng tsa grits ea carbide le lebili.

Haeba u khahlehela Carbide Grits 'me u batla lintlha le lintlha tse ling, u ka ITELANA ka mohala kapa lengolo-tsoibila ka letsohong le letšehali, kapa U RE ROME MAIL botlaaseng ba leqephe.