- Ts'ebetso ea mechine ke e 'ngoe ea mekhoa ea motheo, e pharaletseng le ea bohlokoa ka ho fetisisa indastering ea lehong, e amang ka ho toba katleho ea tlhahiso, litšenyehelo tsa ho sebetsa le tšebeliso ea matla.

- Ha tšebeliso ea lisebelisoa tsa mochine e lumelloa, tlhahiso ea sesebelisoa e itšetlehile haholo ka thepa ea ho itšeha eo thepa ka boeona e ka e etsang. Lisebelisoa tsa mapolanka lia hlokahala ho boloka ho itšeha

- Ka hona, lisebelisoa tsa lisebelisoa tsa mapolanka li tlameha ho ba le boima bo hlokahalang le ho hanyetsa ho roala, matla a lekaneng le ho tiea, le tekanyo e itseng ea mosebetsi (mohlala, welding, mocheso oa mocheso, cu).

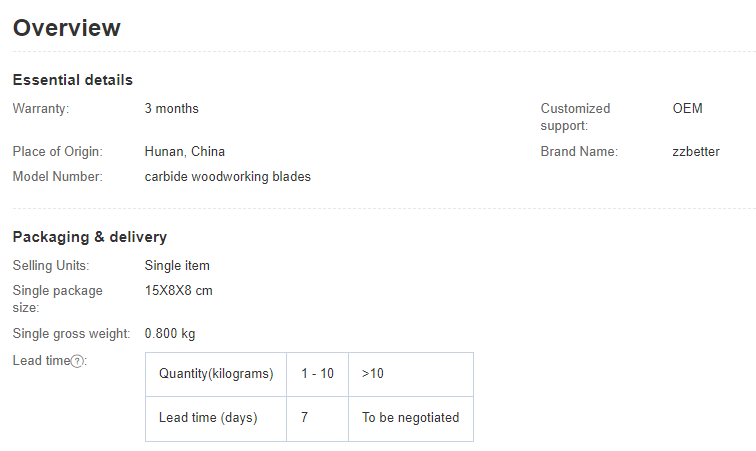

Tlhaloso

Re na le feme e khethehileng ea tungsten carbide, hape re fana ka lihlahisoa tse ling tse ngata tseo re ke keng ra li hlahisa. e ikemiselitseng ho fumana lihlahisoa tse ntle ka ho fetisisa bakeng sa ba batlang ho fumana lihlahisoa tsa boleng bo botle le theko e ntle ka ho fetisisa.

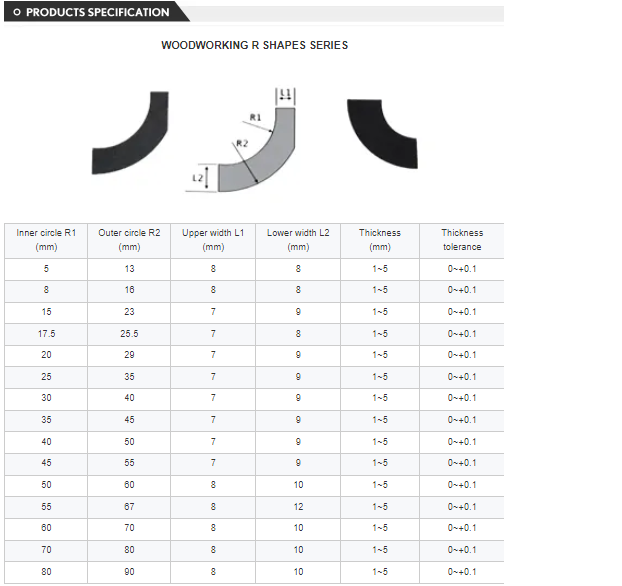

Carbide mapolanka a sehang mahare

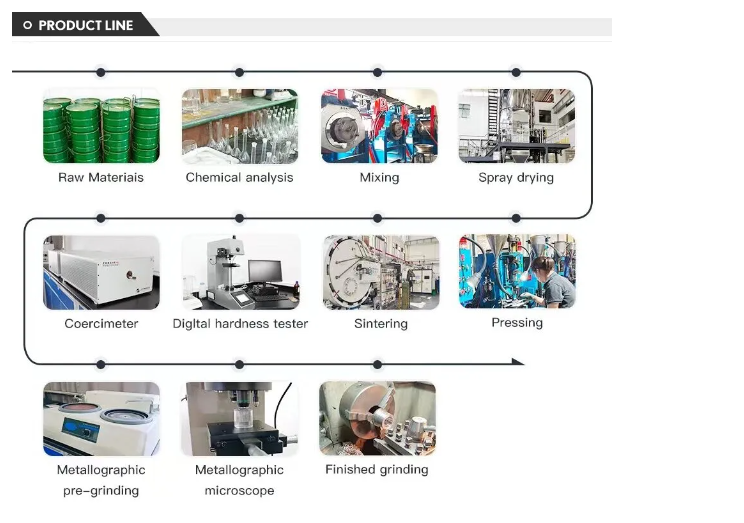

Ts'ebetso ea mechine ke e 'ngoe ea mekhoa ea motheo, e pharaletseng le ea bohlokoa ka ho fetisisa lefapheng la lehong, le amang ka ho toba katleho ea tlhahiso, litšenyehelo tsa ho sebetsa le tšebeliso ea matla. hore thepa ka boeona e ka phetha. Lisebelisoa tsa mapolanka lia hlokahala ho boloka bohale ba sesebelisoa sa ho itšeha ka nako e telele tlas'a lebelo le phahameng le maemo a phahameng. Ka hona, lisebelisoa tsa lisebelisoa tsa mapolanka li tlameha ho ba le boima bo hlokahalang le ho hanyetsa ho apara, matla a lekaneng le ho tiea, le tekanyo e itseng ea mosebetsi (mohlala, ho cheselletsa, ho phekola mocheso, ho itšeha le ho sila).

Li-blades tsa ho seha tsa Carbide li na le likarolo tse latelang:

- Boima bo phahameng, ho hanyetsa ho apara hantle- High elastic modulus- Matla a phahameng a hatellang- Botsitso bo botle ba lik'hemik'hale (ho hanyetsa acid le alkali, ho hanyetsa mocheso o phahameng oa oxidation)- Matla a tšusumetso e tlase- Coefficient e tlase ea ho atolosa, conductivity ea mocheso le motlakase oa motlakase o tšoanang le tšepe le li-alloys tsa eona

Melemo eaMaqhubu a sehang a carbide:

1. Li tsamaisa mahare ka meno a tsona a bohale.2. Ho eketsa bokhoni le tlhahiso ka lebaka la ho rema le ho bōptjoa ha lehong ka potlako.3. Ka lebaka la ho nepahala ha mochine, ho lumellana ha ho itšeha le sebōpeho.4. Ho fokotsa litšenyehelo tsa basebetsi hobane ho hlokahala basebetsi ba fokolang.5. E khona ho sebetsana le lehong le leholoanyane le le boima le ka ba thata ka matsoho feela.

Lisebelisoa tsa lisebelisoa tsa carbide li fetohile lisebelisoa tse ka sehloohong tsa lisebelisoa tsa indasteri ea ho lokisa lehong 'me li tla phetha karolo ea bohlokoa mosebetsing oa ho rema lehong ka nako e telele nakong e tlang. Ka ntlafatso ea theknoloji e fapaneng ea ts'ebetso ea alloy e thata le theknoloji ea ho roala, ts'ebetso ea ho itšeha ea lisebelisoa tse thata tsa alloy e tla tsoela pele ho ntlafala.

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:B/V 12-305, Da Han Hui Pu Industrial Park, Motse oa Zhuzhou, Chaena.

Mohala:+86 18173392980

Mohala:0086-731-28705418

Fax:0086-731-28510897

Email:zzbt@zzbetter.com

Whatsapp / Wechat:+86 181 7339 2980