MWD Parts & Downhole Components Engineering Reliability for Extreme Environments

MWD Parts & Downhole Components Engineering Reliability for Extreme Environments

Measurement While Drilling (MWD) systems are critical for modern directional drilling, providing real-time data on wellbore trajectory, formation properties, and drilling parameters. The performance of MWD parts and downhole components directly impacts operational efficiency, safety, and cost-effectiveness in oil and gas exploration. Among these components, tungsten carbide-based parts play an indispensable role due to their exceptional wear resistance, mechanical strength, and stability under extreme downhole conditions.

Key MWD Components and Their Functions

1. Tool Joints and Wear Bands

- Tungsten carbide-coated wear bands protect drill strings from abrasive formations, reducing friction and extending tool life.

- High-strength tool joints with WC inserts withstand cyclic stress and prevent thread failure.

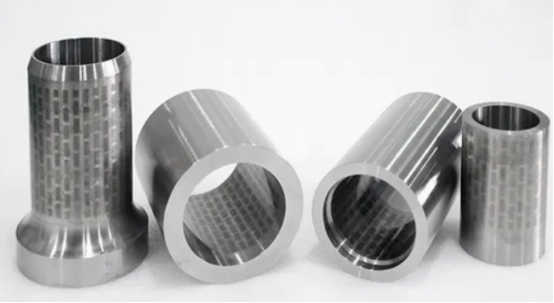

2. Sensor Housings and Probe Components

- WC housings shield sensitive MWD sensors (e.g., gamma ray, pressure transducers) from shock, vibration, and corrosive drilling fluids.

- Precision-ground WC components ensure signal accuracy and reliability.

3. Steering Components

- WC thrust bearings and rotors in mud motors offer high torque resistance and durability in high-RPM applications.

- Non-magnetic WC alloys (e.g., WC-Ni) avoid interference with MWD magnetic surveying tools.

4. Flow Control Parts

- WC nozzles and chokes regulate fluid flow while resisting erosion from abrasive drilling mud.

Why Tungsten Carbide?

- Hardness (1,800-2,200 HV): Outlasts steel by 5-10x in abrasive environments.

- Corrosion Resistance: Performs in H₂S/CO₂-rich formations and high-salinity fluids.

- Thermal Stability: Maintains properties at temperatures up to 500°C.

Manufacturing Excellence

At Zhuzhou Better Tungsten Carbide, we leverage:

- HIP Sintering: Achieves 99.99% density for superior mechanical properties.

- CNC Precision Grinding: Ensures tolerances within ±0.005 mm for seamless integration.

- Non-Destructive Testing: Ultrasonic and X-ray inspection guarantees defect-free components.

Applications Beyond MWD

Our WC components are also trusted in:

- LWD (Logging While Drilling) systems

- HP/HT (High-Pressure/High-Temperature) wells

- Geothermal and mining drilling tools

Conclusion

As drilling operations venture into deeper and more challenging formations, the demand for reliable MWD parts continues to grow. Tungsten carbide’s unique properties make it the material of choice for critical downhole components. Zhuzhou Better combines advanced material science with rigorous quality control to deliver parts that meet API 7-1 and ISO 9001 standards, ensuring your operations run smoothly and efficiently.

Explore our MWD component solutions:

Email: sales@zzbetter.com

Keywords: MWD parts, downhole tools, tungsten carbide drilling components, wear-resistant alloys, directional drilling technology