Intshayelelo ye-Hardfacing kunye ne-Carbide Materials yayo

Intshayelelo ye-Hardfacing kunye ne-Carbide Materials yayo

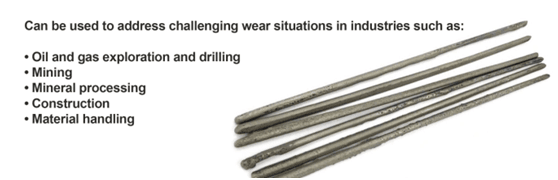

Kwiminyaka edlulileyo ukuqina kobuso kwaba ngumba wophuhliso olunzulu olunxulumene nokunxitywa kwezicelo ezixhathisayo. I-Hardfacing, ekwaziwa ngokuba yi-“Hardsurfacing”, kukusetyenziswa kolwakhiwo okanye ukunganxibi kwentsimbi yeweld kumphezulu wenxalenye ngendlela yokuwelda okanye ukudibanisa ukuxhathisa ukurhawuka, ukubola, ubushushu obuphezulu, okanye impembelelo. Kukubekwa kweengubo ezishinyeneyo zezixhobo eziqinileyo, ezinganxibiyo kwindawo egugileyo okanye entsha enokunxitywa kwinkonzo. Ukutshiza nge-Thermal, i-spray-fuse kunye neenkqubo ze-welding zisetyenziselwa ukusetyenziswa kwe-hardfacing layer. I-alloy enjalo inokuthi ifakwe kumphezulu, emphethweni, okanye nje inqaku lenxalenye enokunxitywa. Iidiphozithi ze-welding zinokusebenza umphezulu kwaye zibuyise iinxalenye ezandisa ubomi babo benkonzo. I-Welding iteknoloji ephambili yokuzalisekisa ezi mfuno kunye nokusebenzisa i-alloys enzima. Amalungu angundoqo afana nezityuli abonakaliswe ekunxityweni okunzima kwaye afuna amanyathelo asebenzayo okukhusela umphezulu ukuze aphephe ukuhla kweendleko kunye nokunciphisa iindleko zeendawo ezinqabileyo ezinqabileyo. Le nkqubo yamkelwe kumashishini amaninzi afana ne-Cement, iMining, i-Steel, i-Petro-chemical, i-Power, i-Sugar cane kunye noKutya.

I-Tungsten carbide yenye yezona zinto zinzima ezikhoyo kusetyenziso lwemizi-mveliso. Ayinakunyibilikiswa naliphi na ilangatye eliqhelekileyo lobushushu obuphantsi. Kwakhona kunokuba brittle. Ngeenjongo ezijongene nobunzima, iyachithwa kwaye isetyenziswe ngokubambisana nentsimbi "ebophezelayo". Iinqununu ze-tungsten carbide zivame ukuvalelwa kwintsimbi yentsimbi.

I-ZZBETTER inezixhobo zokuwelda ezilukhuni ngolu hlobo lulandelayo:

1.Iifakelo zeTungsten Carbide Wear:

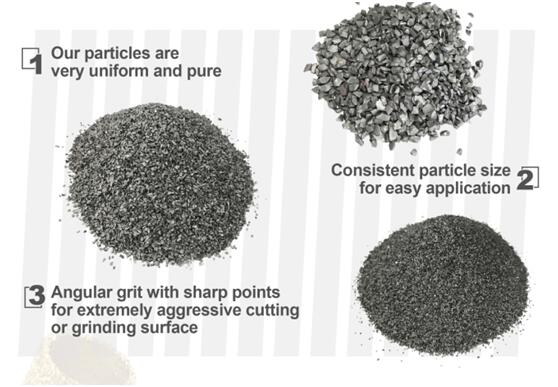

2.I-Tungsten Carbide Grits: I-Tungsten carbide grit ibonelela ngokhuseleko lokunxiba oluhlala ixesha elide kwiindawo zokunxitywa okuphezulu kwe-abrasive. Isetyenziselwa ukukhusela iindawo ezinexabiso eliphezulu ezinje ngeencakuba zebulldozer, amazinyo eemele, ukugawula iinkuni, ihamile, amazinyo etrencher, nezinye izinto ezininzi ezinokusetyenziswa. I-Tungsten Carbide grit yindlela efanelekileyo yokukhusela oomatshini kunye neengxenye zoomatshini ngokubonelela ngokunyuka okubonakalayo kubomi obude bezo ndawo. Oku kunciphisa ixesha lokuphumla kwaye kunciphisa iindleko ezibandakanyekayo kunye namalungu angakhuselekanga.

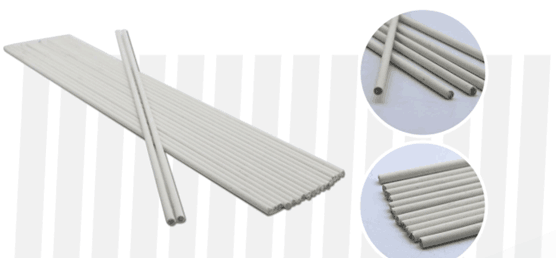

3.Iinduku ezidityanisiweyo ezineCarbide Insert: Ezi rodi ziphezulu ezidityanisiweyo zisebenzisa i-carbide yethu yokufaka ikunika imiphetho ebukhali yokusika kunye nokomelela okufunekayo kwiindawo ezibalulekileyo zesixhobo sakho sokugaya.

4.Iinduku zeNickel Carbide Composite: I-nickel carbide composite rods ibe yi-hardfacing kunye nokulungiswa kweebhithi ze-cutter ezisisigxina kwaye zisetyenziswe njengokhuseleko lokunxiba lwe-stabilizers kunye ne-reamers kwishishini leoli kunye negesi. Iipellets ezinkulu ze-tungsten carbide zibonelela ngokumelana ne-abrasion ngelixa iipellets ezicolekileyo zikhusela i-matrix ekugugile kunye nokukhukuliseka. I-nickel matrix ibonelela ngobushushu obuphezulu be-corrosion ukumelana, ukukhusela i-bit body kunye nokuvumela ukulungiswa kwe-cutter kunye nokuphinda kusetyenziswe intloko ye-drill.

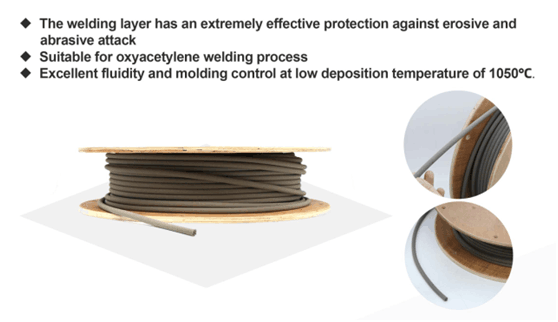

5.Intambo yeWelding ethambileyo: Intambo ye-welding eguquguqukayo yenziwe kwi-tungsten carbide etyhidiweyo, i-spherical cast tungsten carbide okanye umxube wesibini njengesigaba esinzima, i-self-fluxing nickel alloy powder yesigaba sokudibanisa, ngokomlinganiselo othile wokudibanisa okuxubileyo, ukubunjwa kwe-extrusion, ukomisa, kwaye emva koko yenziwe kwi-nickel wire.

6.Iintonga zeNickel zeSilver Tinning: Iintsimbi ze-nickel zesilivere ze-toni ze-oxyacetylene zenjongo jikelele zokuwelda iintsimbi ezahlukeneyo ze-ferrous kunye ne-non-ferrous, njengentsimbi, isinyithi esityhidiweyo, isinyithi esithambileyo, kunye ne-nickel alloys. Zidla ngokusetyenziselwa ukudityaniswa kwe-welding yobhedu, ubhedu, kunye ne-alloys yobhedu kunye nokwakha iindawo ezigugileyo.

7.Phosa iTungsten Carbide Powder: I-Cast tungsten carbide powder, eyaziwa ngokuba yi-W2C, yinto enzima kakhulu esetyenziswa kwizicelo ezahlukeneyo. Ngesakhiwo se-eutectic, indawo ephezulu yokunyibilika kunye nobunzima, obunokunceda ekukhuseleni ukugqoka kunye neempawu zokumelana. Izinto eziphathekayo zenziweukusuka kumxube wekhabhoni, itungsten kunye netungsten carbide powder kwaye iyisilivere/ngwevu ngombala kunye nokumila kwesuntswana elibukhali.

8.Iintonga zeTungsten Carbide Pellet Welding: Xa kuthelekiswa ne-cast tungsten carbide powder, iipellets ze-tungsten carbide zinempembelelo engcono kunye nokumelana nokunxiba. Ineempawu ze-welding yexesha elinye ngaphandle kwe-reflow soldering. Iipellets zingqukuva; i-friction coefficient incinci, enokunciphisa ukunxiba kwe-casing kunye neendleko ezisebenzayo.

Umbuzo: Ngaba i-hardfacing ifanelekile?

I-Hardfacing inokufezekiswa ngokusebenzisa iinkqubo ezahlukeneyo, zombini kwivenkile nakwintsimi, okwenza kube yinto eninzi kakhulu kwaye ingabizi. Ukongeza, ukusebenzisa le nkqubo kumacandelo amatsha kunokwandisa ubomi benkonzo ukuya kuthi ga kwi-300%. Nangona kunjalo, ukuba unxibe iindawo ezinzima, ungagcina ukuya kuthi ga kwi-75% xa uthelekisa neendleko zokutshintsha.

Ukugqiba, i-hardfacing yeyona nkqubo iguquguqukayo yokuphucula ubomi becandelo eligugileyo; i-hardfacing yeyona nkqubo ikhethwayo kule mihla yokunciphisa iindleko zokutshintshwa; i-hardfacing inciphisa ixesha lokuphumla ngenxa yokuba iindawo zihlala ixesha elide kwaye ukuvalwa okumbalwa kuyafuneka ukuze kutshintshe; i-hardfacing inokwenziwa nakweyiphi na impahla yentsimbi kusetyenziswa iindlela ezahlukeneyo zokuwelda.

Ukuba unomdla kwiimveliso ze-tungsten carbide kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, ungaQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL ezantsi kweli phepha.