Unyango oluqhelekileyo lweMetal Surface

Unyango oluqhelekileyo lweMetal Surface

Ingcamango yonyango lomphezulu wesinyithi

Ibhekisa kwinkqubo yokutshintsha ubume bomphezulu kunye neempawu zenxalenye kunye nokwandisa indibaniselwano yayo kunye nemathiriyeli yematriki ukuhlangabezana neemfuno zokusebenza ezimiselweyo ngokusebenzisa ubugcisa obutsha obuphambili kwifiziksi yanamhlanje, ikhemistri, isinyithi, kunye nonyango lobushushu.

1. Ukuguqulwa kweMetal Surface

Iqulethe ezi ndlela zilandelayo: ukuqina komphezulu, ukuqhunyiswa kwesanti, ukugquma, ukuzoba, ukupeyisha, ukuqina komphezulu welaser.

(1) ukuqina komphezulu wentsimbi

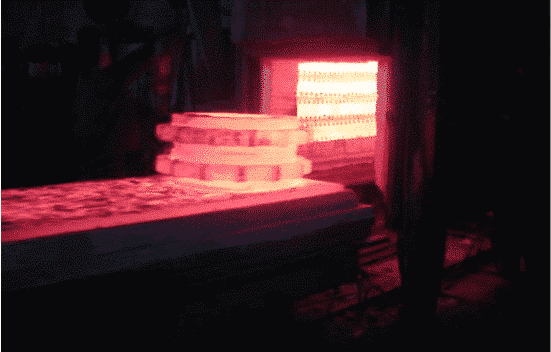

Yindlela yonyango yokushisa eyenza i-austenitizes i-surface layer kwaye ipholise ngokukhawuleza ukuqinisa umphezulu ngaphandle kokutshintsha ukubunjwa kweekhemikhali zentsimbi.

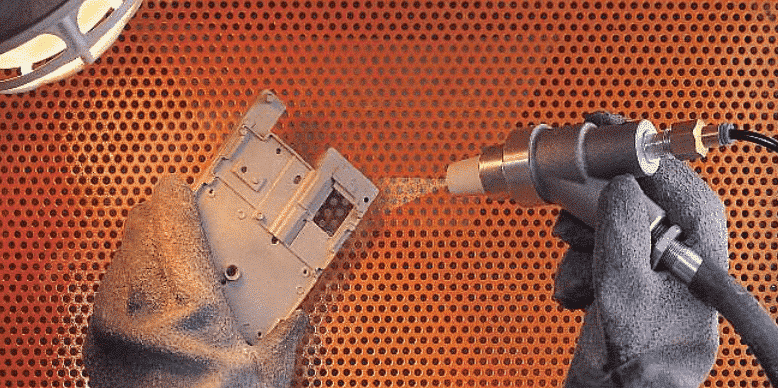

(2) umphezulu wesinyithi oqhutyiweyo

I-workpiece surface ichaphazeleka yintlabathi yesantya esiphezulu kunye neengqungquthela zensimbi, ezingasetyenziselwa ukuphucula iimpawu zomatshini zenxalenye kunye nokutshintsha umgangatho ophezulu. Lo msebenzi unokuphucula ngokufanelekileyo amandla omatshini, ukuxhathisa ukunxiba kunye nokuphelisa uxinzelelo olushiyekileyo.

(3) ukuqengqeleka komphezulu wesinyithi

Kukucinezela umphezulu we-workpiece kunye ne-roller eqinile kwiqondo lokushisa lokushisa ukwenzela ukuba umphezulu we-workpiece ungaqiniswa yi-deformation yeplastiki ukuze ufumane indawo echanekileyo kunye negudileyo.

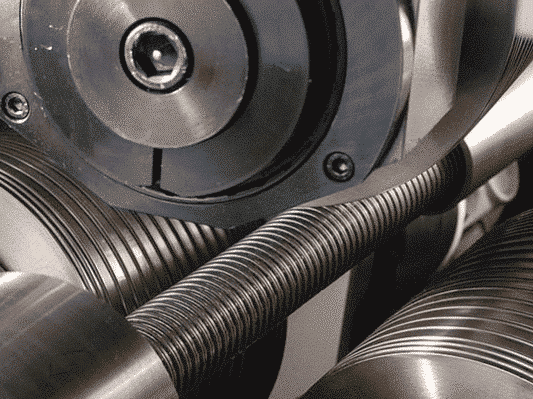

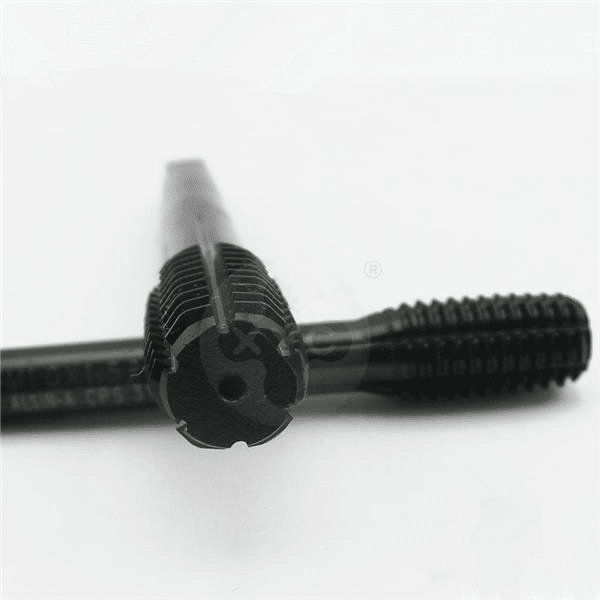

(4) umphezulu wesinyithi obrashiweyo

Ngaphantsi kwamandla angaphandle, isinyithi sinyanzeliswa ngokufa. I-cross-section yentsimbi ixinzelelwe ukuba itshintshe imilo kunye nobukhulu bayo. Le ndlela ibizwa ngokuba ngumzobo wocingo. Ngokweemfuno zokuhombisa, umzobo wocingo unokwenziwa kwiintlobo ngeentlobo zemisonto, efana nethe tye, i-crimped, i-wavy, kunye ne-threaded.

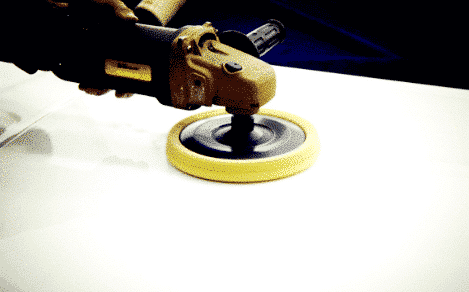

(5) ukugulisa umphezulu wesinyithi

Ukupholisha yindlela yokugqiba yokuguqula umphezulu wenxalenye. Inokufumana kuphela indawo egudileyo ngaphandle kokuphucula ukuchaneka komatshini. Ixabiso Ra umphezulu ogudisiweyo unako ukufikelela 1.6-0.008 um.

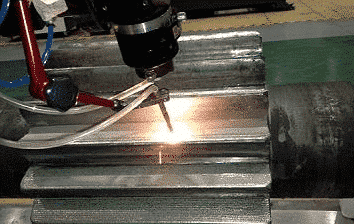

(6) Ukuqiniswa kweLaser yemigangatho yentsimbi

I-laser beam egxininisiweyo isetyenziselwa ukutshisa i-workpiece ngokukhawuleza kwaye emva koko ipholise ngokukhawuleza i-workpiece ukuze ifumane indawo eqinile kunye neyomeleziweyo. Ukomelezwa komphezulu weLaser kuneenzuzo zokuguqulwa okuncinci, ukusebenza ngokulula, kunye nokomelezwa kwendawo.

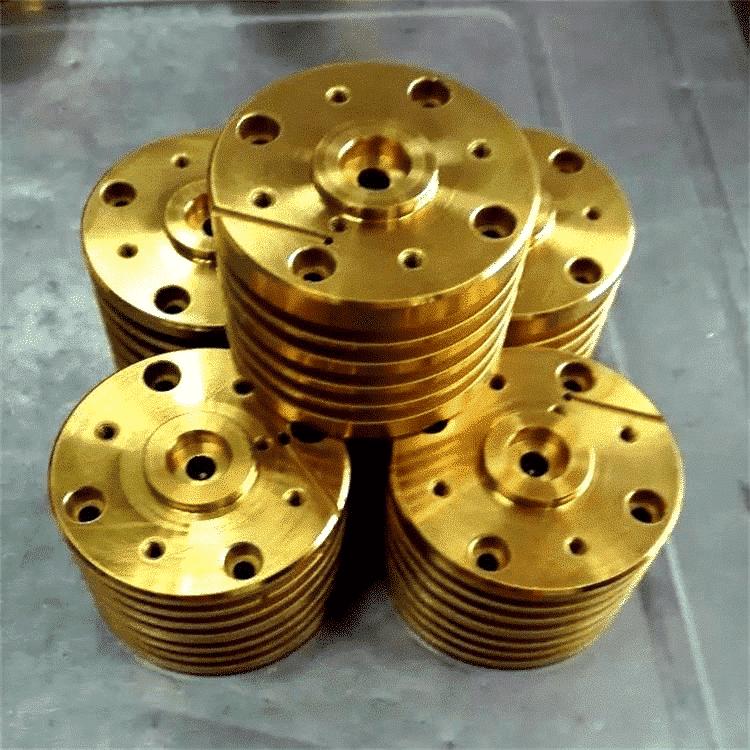

2. ITekhnoloji yoKwabelana ngeNtsimbi kumphezulu

Ngeendlela eziphathekayo, izinto ezongezelelweyo zongezwa kwi-matrix ukwenza i-alloy layer. I-carburizing eqhelekileyo kunye ne-nitriding yobobu buchule. Ibeka isinyithi kunye ne-ejenti yokungena kwigumbi elifanayo elitywiniweyo, isebenze i-metal surface ngokufudumeza kwe-vacuum, kwaye yenza i-carbon kunye ne-nitrogen ingene kwi-matrix yetsimbi ngendlela yee-athomu ukuze kufezekiswe injongo ye-alloying.

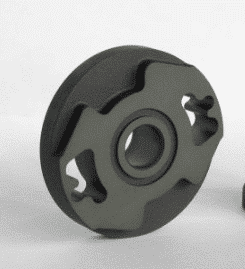

(1) Ubumnyama: Ifilimu ye-oxide emnyama okanye eluhlaza okwesibhakabhaka iveliswa ukwahlula umoya kwi-corrosion ye-workpiece.

(2) i-phosphating: Indlela yonyango yesinyithi ye-electrochemical esetyenziselwa ukukhusela isinyithi esisisiseko ngokufaka i-phosphates ecocekileyo, engaxutywanga namanzi kumphezulu wezinto zokusebenza ezintywiliselwe kwisisombululo sephosphating.

Akukho namnye kubo ochaphazela isakhiwo sangaphakathi se-workpiece. Umahluko kukuba intsimbi emnyama yenza i-workpiece ibengezele, ngelixa i-phosphating yongeza ubukhulu kwaye ibuthuntu ubuso bomsebenzi. I-Phosphating ikhusela ngakumbi kune-blackening. Ngokwexabiso, ubumnyama budla ngokubiza kakhulu kune-phosphating.

(3) itekhnoloji yokwambathisa yentsimbi

Ukugquma okanye ukugquma kwenziwa kumphezulu we-substrate ngeendlela ze-physicochemical. Isetyenziswa ngokubanzi kwizixhobo zokusika i-carbide.

I-TiN yokugqoka kunye ne-TiCN yokugqoka kwindawo yesinyithi

Iimicrons ezimbalwa ezityebileyo I-Tin Kwizixhobo zokusika ezisika ubhedu oluthambileyo okanye intsimbi ethambileyo, izinto zihlala zigolide.

Iingubo ezimnyama ze-titanium nitride zidla ngokusetyenziswa apho i-friction coefficient incinci kodwa ukuqina kuyafuneka.

Oku ngasentla sisingeniso sethu esifutshane kunyango lwentsimbi. Ukuba unomdla kwiimveliso ze-tungsten carbide kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, ungaQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL emazantsi ephepha.