Indlela yokukhetha eyona Mili yokuphela

Kwenziwa kanjaniCihubhui BEstEnd-Muyagula

Iimishini zokuphelisa zizixhobo ezibalulekileyo ezisetyenziswa kwimisebenzi yokusila ukusika kunye nokubumba izinto ezahlukeneyo, njengentsimbi, iinkuni kunye neeplastiki. Umgangatho wesixhobo sokusila uchaphazela kakhulu iziphumo zobuchwephesha, ubomi besixhobo, kunye nemveliso iyonke. Indlela yokufumana eyona mill ilungileyo neyona ifanelekileyo? Kweli nqaku, siza kuxoxa ngezinto eziphambili ekufuneka ziqwalaselwe xa ukhetha umenzi wesixhobo sokusila kunye nemilinganiselo yomgangatho we-end Mill.

Iimishini zokuphelisa zizixhobo ezibalulekileyo ezisetyenziswa kwimisebenzi yokusila ukusika kunye nokubumba izinto ezahlukeneyo, njengentsimbi, iinkuni kunye neeplastiki. Umgangatho wesixhobo sokusila uchaphazela kakhulu iziphumo zobuchwephesha, ubomi besixhobo, kunye nemveliso iyonke. Indlela yokufumana eyona mill ilungileyo neyona ifanelekileyo? Kweli nqaku, siza kuxoxa ngezinto eziphambili ekufuneka ziqwalaselwe xa ukhetha umenzi wesixhobo sokusila kunye nemilinganiselo yomgangatho we-end Mill.

Ungamkhetha njani umenzi weMila yokuPhelisa?

Ukukhetha umenzi wokusila ochanekileyo kubalulekile ukuqinisekisa umgangatho, ukusebenza, kunye nokuphila ixesha elide kwezi zixhobo zokusika.

1. Udumo kunye namava:

Enye yezinto zokuqala ekufuneka ziqwalaselwe ludumo lomenzi kunye namava kwishishini. Khangela abavelisi abanerekhodi eqinisekisiweyo yokuvelisa i-mills ekupheleni komgangatho ophezulu. Qwalasela iminyaka yabo yamava, iziqinisekiso, kunye nophononongo lwabathengi. Umenzi ohloniphekileyo kunokwenzeka ukuba abonelele ngee-mills ezithembekileyo nezizinzileyo.

2. Ubunakho bokuVelisa:

Kubalulekile ukuqonda amandla okwenza umvelisi wokuphela komatshini. Khangela abavelisi abanoomatshini abaphambili, amaziko asemgangathweni, kunye nokuzinikela okuqinileyo kulawulo lomgangatho. Umenzi onobuchule obungaphakathi kwindlu yokuyila, ukugaya, kunye nokugquma i-coating end Mills unokunika ulawulo olungcono kumgangatho kunye nokusebenza kwezixhobo.

3. Ukukhethwa kweMathiriyeli kunye neeNgqungquthela:

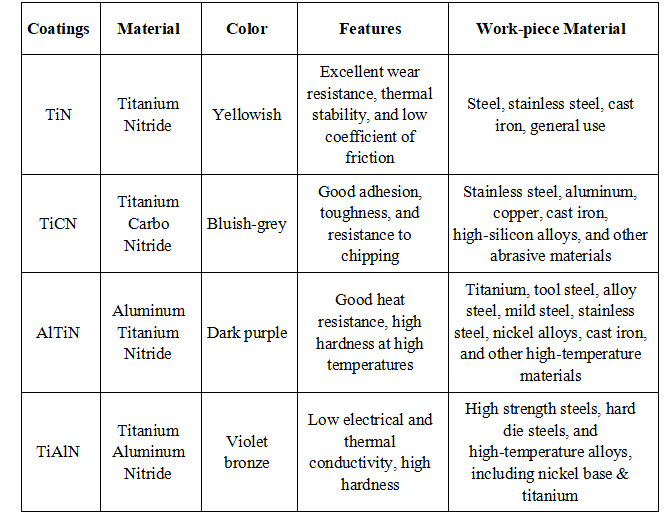

Qwalasela uluhlu lwezixhobo ezibonelelwa ngumenzi kwimizila yokuphela. Izinto ezahlukeneyo, ezifana ne-high-speed steel (HSS), i-carbide, kunye ne-cobalt, zineempawu ezahlukeneyo kunye neempawu zokusebenza. Umenzi olungileyo kufuneka anikezele ngezinto ezahlukeneyo zokuhlangabezana neemfuno ezahlukeneyo zomatshini. Ukongeza, buza malunga nokufumaneka kweengubo ezahlukeneyo, ezinje ngeTiN, TiAlN, kunye neDLC, ezonyusa ukuqina nokusebenza kwesixhobo.

4. Ukhetho Lwenu:

Yonke inkqubo yomatshini ineemfuno zayo ezizodwa. Umvelisi othembekileyo wokusila kufuneka anike iinketho zokwenza ngokwezifiso ukuhlangabezana neemfuno ezithile. Oku kunokubandakanya iijiyometri zesixhobo esiqhelekileyo, iingubo ezikhethekileyo, okanye ubude besixhobo esilungisiweyo. Umenzi onobuchule bokwenza ngokwezifiso ii-mills zokugqibela unokubonelela ngezisombululo ezilungelelanisiweyo ezandisa ukusebenza kunye nemveliso.

5. Inkxaso yobuGcisa kunye neNkonzo yabaThengi:

Qwalasela inqanaba lenkxaso yobugcisa kunye nenkonzo yabathengi ebonelelwa ngumenzi. Umenzi olungileyo kufuneka abe neengcali ezinolwazi ezinokunika isikhokelo ekukhetheni isixhobo, ukusetyenziswa, kunye nokusombulula ingxaki. Khangela abavelisi ababonelela ngenkonzo yabathengi ekhawulezayo nephendulayo ukujongana nayo nayiphi na inkxalabo okanye imiba enokuthi ivele.

6. Ixabiso kunye neXabiso:

Ngelixa ixabiso liyingqwalasela ebalulekileyo, akufanele kube yiyo yodwa into emiselayo. Amashishini angabizi kakhulu angagcina imali ekuqaleni, kodwa asenokungabi nako ukuhlala kunye nokusebenza. Khangela abavelisi ababonelela ngamaxabiso akhuphisanayo ngelixa behambisa ixabiso elihle kumgangatho kunye nokusebenza kweemill zabo zokuphela. Qwalasela iindleko zizonke ngesixhobo kunye nobomi besixhobo obulindelekileyo ukwenza isigqibo esinolwazi.

Ukukhetha umenzi womatshini wokusila ochanekileyo kubalulekile ekuphumezeni ezona ziphumo zilungileyo zokusila. Qwalasela izinto ezinjeisidima, amava, amandla okwenza izinto, ukhetho lwezinto eziphathekayo, ukhetho lokulungelelanisa, inkxaso yobugcisa kunye nexabiso.Ngokuphonononga ngononophelo ezi zinto, unokukhetha umenzi othembekileyo obonelela ngezixhobo zokugqibela ezikumgangatho ophezulu, ukuqinisekisa ukusebenza kakuhle, ukuchaneka, kunye nokuphila ixesha elide kwimisebenzi yakho yokusila.

Uwugwebe njani uMgangatho we-End Mill?

1. Umgangatho Wezinto:

Inkalo yokuqala ekufuneka iqwalaselwe yimathiriyeli esetyenziselwa ukwenza i-end Mill. Izixhobo zokugqibela ezikumgangatho ophezulu zenziwe ngezinto ezifana ne-carbide okanye i-high-speed steel (HSS). Izixhobo zokugqibela zeCarbide ziyaziwa ngobulukhuni bazo obukhethekileyo kunye nokunganyangeki kokunxiba, okubenza bafanelekele ukufakwa kwezicelo zoomatshini. Izixhobo zokugqibela ze-HSS zibonelela ngokuqina okulungileyo kwaye zingabizi kakhulu kwizicelo ezingabizi kakhulu. Jonga iinkcukacha zomenzi ukuqinisekisa ukuba isiphelo sokusila senziwe kwizinto ezikumgangatho ophezulu ezihambelana neemfuno zakho zokwenza.

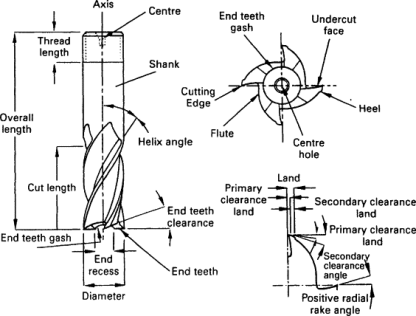

2. Ukuchaneka koMveliso:

Ukuchaneka okwenziwa ngayo isingqusho sokuphela kunempembelelo enkulu ekusebenzeni kwayo. Khangela ii-mills zokugqibela eziveliswa ngokunyamezela okuqinileyo kunye nokuchaneka okuphezulu. Jonga iimpawu zokuchaneka kuyilo lwesixhobo, njengefluti elinganayo, imiphetho echanekileyo yokusika, kunye nemilinganiselo echanekileyo. Umatshini wokugqiba owenziwe kakuhle uya kuba nejometri engaguqukiyo kuso sonke isixhobo, iqinisekisa iziphumo ezichanekileyo kunye neziphindaphindwayo zomatshini.

3. Umgangatho Wokwambathisa:

Iingubo ezifakwe kwi-end Mills ziphucula ukusebenza kwazo ngokunciphisa ukukhuhlana, ukwandisa ubulukhuni, kunye nokuphucula ukukhupha i-chip. Izixhobo zokugqibela ezikumgangatho ophezulu zihlala zigqunywe ngezinto ezifana ne-titanium nitride (TiN), i-titanium aluminium nitride (TiAlN), okanye i-diamond-like carbon (DLC). Xa ujonga umgangatho wesixhobo sokusila, jonga i-coating, ukuguda, kunye nokuncamathela. Ingubo yomgangatho ophezulu iya kusetyenziswa ngokulinganayo, ikhululekile kwiziphene, kwaye ibe nokunamathela kakuhle kwindawo yesixhobo.

Ezinye zezona coatings ezisisiseko ze-end Mills

4. Ukomelela komphetho kunye nokuKhathalela:

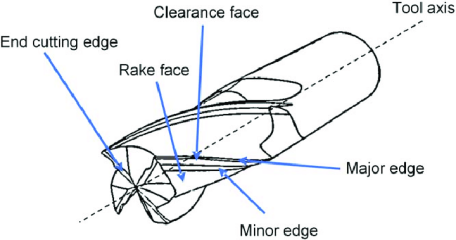

Umphetho wokusika we-end Mill ubalulekile ekufezekiseni ukusika okuchanekileyo kunye nokusebenza kakuhle. Hlola umda wokusika phantsi kokukhulisa ukuvavanya amandla kunye nobukhali. I-mill ye-high-quality end mill iya kuba ne-cut cut edge ekhululekileyo kwi-chips okanye i-nicks. Umphetho wokusika kufuneka ubonise amandla afanelekileyo kunye nokuchasana nokunxiba, ukuqinisekisa ubomi besixhobo obude kunye nokusebenza kokusika okungaguqukiyo.

5. Ukukhutshwa kweChip:

Ukukhutshwa kwetshiphu okusebenzayo kubalulekile ekuthinteleni ukwakheka kwetshiphu kunye nokuphucula ukusebenza kukonke kwesixhobo sokusila. Jonga ii-end Mills ezinefluti eziyilwe kakuhle ezivumela ukukhutshwa kwetshiphu egudileyo. Iifluti kufuneka zibe nezithuba ezifanelekileyo, ubunzulu, kunye nokumila ukuze kube lula ukususwa kweetshiphusi kwindawo yokusika. Ukuphelisa oomatshiningezakhono zokukhutshwa kwetshiphu ezisebenzayo zinceda ukuthintela ukugcwala kwesixhobo, ukugcwala kobushushu, kunye nokusilela kwesixhobo kwangaphambi kwexesha.

6. Ukusebenza kunye noBomi besixhobo:

Eyona jaji yomgangatho wesixhobo sokusila kukusebenza kwayo kunye nobomi besixhobo. Vavanya isakhono somatshini wokugqiba ukuphumeza ukusikwa okuchanekileyo, ukugcina ukubukhali, kunye nokubonelela ngeziphumo ezingaguqukiyo. Qwalasela ubomi besixhobo kunye nendlela isisila esigcina ngayo ukusebenza kwayo ngokuhamba kwexesha. Izixhobo zokugqibela ezikumgangatho ophezulu ziza kubonisa ubomi obude besixhobo, ukunciphisa izixhobo zokusebenza, kunye nokusebenza okungaguqukiyo, okukhokelela ekuphuculweni kwemveliso kunye nokusebenza kakuhle kweendleko.

Ukujonga umgangatho wesixhobo sokusila kufuna ukuphononongwa ngononophelo kwezinto ezininzi, kubandakanya umgangatho wezinto eziphathekayo, ukuchaneka kwemveliso, umgangatho wokugquma, amandla okusika kunye nokubukhali, amandla okukhutshwa kwe-chip, kunye nokusebenza ngokubanzi. Ngokuqwalasela le miba, ungakhetha i-end Mill ekumgangatho ophezulu.

Ukuba unomdla kwi-tungsten carbide studs kwaye ufuna ukufumana ulwazi oluthe kratya, nceda Qhagamshelana nathi ngenombolo yefowuni okanye i-imeyile ekhohlo okanye Sithumele i-imeyile ezantsi kwephepha.