Ukuphucula njani ukuNxitywa kwezahlulo zokunxiba zeCarbide?

Ukuphucula njani ukuNxitywa kwezahlulo zokunxiba zeCarbide?

Ukusebenza kokugqoka kwe-tungsten carbide kuchaphazelekayo kusetyenziso lwendalo kunye nokusebenza kwe-alloy. Ukuxhatshazwa kokugqoka kunqunywe ngokukodwa yi-microstructure kunye nokubunjwa kweekhemikhali. Iiparamitha eziphambili zesakhiwo se-carbide ene-cemented ubukhulu beenkozo kunye nomxholo wesigaba sokudibanisa. Ukuxhatshazwa kokugqoka kuphinda kuchaphazeleke kwizinto ezongezelelweyo ezifana ne-barium.

Kwimveliso yemizi-mveliso, izixhobo ezibaluleke kakhulu zoomatshini kunye neenxalenye zabo zoomatshini zikwimeko enzima, njengesantya esiphezulu, ubushushu obuphezulu, uxinzelelo oluphezulu, ukusebenzela kakhulu, njl. oxidation, ezibangelwa ubukhulu becala ngumphezulu.

Amanyathelo okukhusela angaphezulu asetyenziselwa ukulibaziseka nokulawula umonakalo, oye waba yindlela esebenzayo yokusombulula ukunxiba kwamacandelo omatshini. Ke ngoko, iindlela ezahlukeneyo zobuchule bokurhuqa umphezulu weendawo zoomatshini zamkelwa, ezinje ngokutyabeka, i-thermos, i-carburizing, i-nitriding, isinyithi esinokungena, ukutshiza okushushu, ukugquma komhlaba, ukugquma, kunye nokuncamathisela umaleko wokuqina, umqadi wamandla aphezulu, njl.

Umhlaba onqabileyo usetyenziswe ngempumelelo kwi-carbide wear part. Xa amandla kunye nokuqina kwempembelelo kunyuka ngaphezu kwe-10%, ukunyanzeliswa kokunxiba kweendawo zokunxiba ze-carbide nako kuphucula.

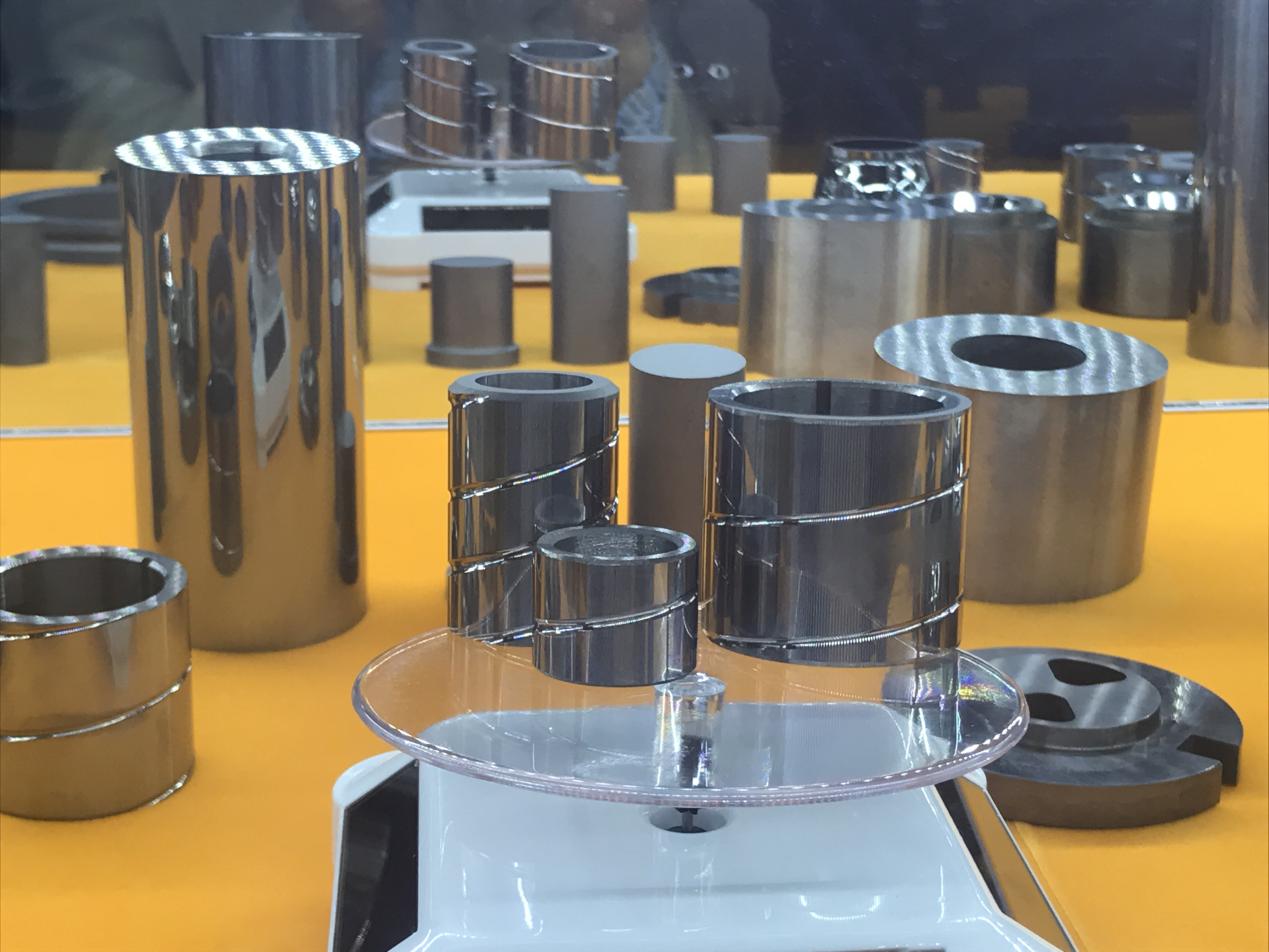

Umzekelo, iinxalenye ze-tungsten carbide mold zisebenza kakuhle kwaye zisetyenziswa ngokubanzi kwishishini lokulungisa iindawo zokubumba. Ukuze ukwandise ixabiso layo, kubalulekile ukuphucula ukunyanzeliswa kwe-tungsten carbide mold parts.

Ngokubanzi, eyona ndlela isebenzayo kunye nethe ngqo yokuphucula ukuxhathisa ukunxiba kwe-tungsten carbide mold parts yi-titanium plating processing-ubomi bomphezulu, ukuqina, ukongezwa kwexabiso kunye nokumelana nokunxiba, ukuxhathisa ukubola, njl.

Umphezulu wokuchaneka kobunzima bokufa obufakwe nge-vacuum coefficient unokuba ne-coefficient ephantsi kakhulu yokukhuhlana, okunciphisa amandla okusebenza. Isitampu esibandayo kunye nokuzoba ukufa okugqunywe nge-vacuum coating kunokunciphisa kakhulu ukukhuhlana, ukukrwela, kunye nokunxiba ngexesha lokulungiswa. Ke ngoko, inokunyusa ubude bobomi kwaye inciphise iindleko kakhulu.

Izinto eziluncedo:

1. Ukunciphisa i-friction coefficient, ukunciphisa amandla okusebenza, ukuphucula ubulukhuni bomhlaba, kunye nokwandisa kakhulu ubomi bokufa.

2. Ekusebenziseni idayizi, ingxaki yokungaphumeleli kwangoko isoloko isonjululwa.

3. Yenza eyona nto igqwesileyo yomsebenzi ukuze udlale indima epheleleyo.

4. Ukuphucula ngamandla umgangatho (njengobunzima bomphezulu, ukuchaneka, njl.) kunye nobomi benkonzo yeendawo zokubumba, ukwenzela ukuba badlale amandla emveliso ngokufanelekileyo.

Ukuba unomdla kwiimveliso ze-tungsten carbide kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, ungaQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL emazantsi ephepha.