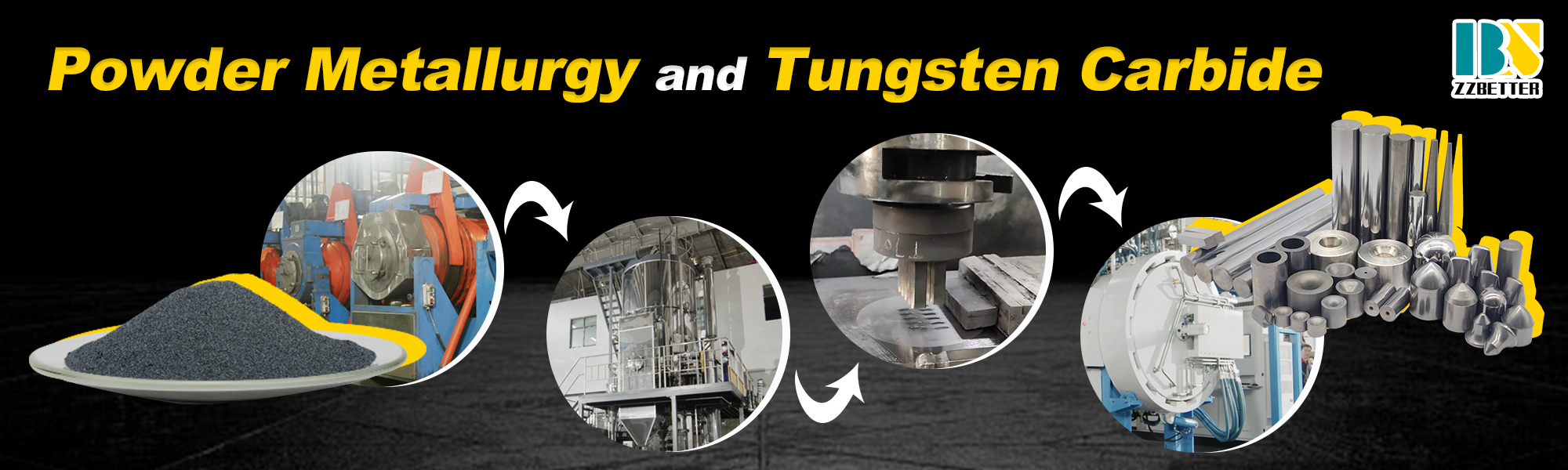

Umgubo weMetallurgy kunye neTungsten Carbide

Umgubo weMetallurgy kunye neTungsten Carbide

Kumashishini anamhlanje, iimveliso ze-tungsten ze-carbide zenziwe ikakhulu ngumgubo wesinyithi. Unokuba nemibuzo emininzi malunga ne-powder metallurgy kunye ne-tungsten carbide. Yintoni i-powder metallurgy? Yintoni tungsten carbide? Kwaye yenziwa njani i-tungsten carbide ngumgubo wesinyithi? Kweli nqaku lide, uya kufumana impendulo.

Umxholo ophambili weli nqaku ngolu hlobo lulandelayo:

1.Isinyithi somgubo

1.1Intshayelelo emfutshane yomgubo wesinyithi

1.2 Imbali yomgubo wesinyithi

1.3Impahla eza kuveliswa ngomgubo wesinyithi

1.4Inkqubo yokuvelisa ngomgubo wesinyithi

2.Tungsten carbide

2.1Intshayelelo emfutshane yetungsten carbide

2.2 Izizathu zokusetyenziswa komgubo wesinyithi

2.3 Inkqubo yokuvelisa i-tungsten carbide

3.Summary

1.Isinyithi somgubo

1.1Intshayelelo emfutshane yomgubo wesinyithi

I-Metallurgy ye-Powder yinkqubo yokuvelisa ukwenza izinto okanye amacandelo ngokudibanisa umgubo kwimilo ethile kunye nokuwufaka phantsi kobushushu obungaphantsi kwamanqaku okunyibilika. Le ndlela ayiqatshelwa njengendlela ephezulu yokuvelisa iindawo ezikumgangatho ophezulu kude kube yikota yekhulu leminyaka eyadlulayo. Inkqubo ye-tungsten carbide ibandakanya ikakhulu iinxalenye ezimbini: enye idibanisa ipowder kwi-die, kwaye enye ifudumeza i-compact kwindawo yokukhusela. Le ndlela inokusetyenziselwa ukuvelisa uninzi lwamacandelo e-metallurgy yesakhiwo, i-self-lubricating bear, kunye nezixhobo zokusika. Ngethuba le nkqubo, i-metallurgy yomgubo inokunceda ukunciphisa ilahleko yezinto eziphathekayo kunye nokunciphisa iindleko zeemveliso zokugqibela. Ngokubanzi, i-metallurgy engumgubo ilungele ukwenziwa kwezo mveliso ziya kuxabisa kakhulu ngenye inkqubo okanye ezohlukileyo kwaye zinokwenziwa kuphela ngomgubo wesinyithi. Enye yeenzuzo ezinkulu zesinyithi somgubo kukuba inkqubo yesinyithi yomgubo ibhetyebhetye ngokwaneleyo ukuvumela ukuthungwa kweempawu ezibonakalayo zemveliso ukuze zihambelane nepropati yakho ethile kunye neemfuno zokusebenza. Ezi mpawu zomzimba ziquka isakhiwo esiyinkimbinkimbi kunye nokuma, i-porosity, ukusebenza, ukusebenza koxinzelelo, ukufunxa ukungcangcazela, ukuchaneka okukhulu, ukugqiba kakuhle kwendawo, uchungechunge olukhulu lweengcezu ezinokunyamezela okuncinci, kunye neempawu ezikhethekileyo ezifana nobunzima kunye nokumelana nokunxiba.

1.2 Imbali yomgubo wesinyithi

Imbali ye-powder metallurgy iqala ngomgubo wesinyithi. Ezinye iimveliso zomgubo zafunyanwa kumangcwaba aseYiputa ngenkulungwane yesithathu BC, kunye nentsimbi non-ayoni kunye nentsimbi zafunyanwa phakathi-mpuma, emva koko zasasazeka eYurophu naseAsia. Iziseko zenzululwazi ze-powder metallurgy zafunyanwa ngusosayensi waseRashiya uMikhail Lomonosov ngekhulu le-16. Ungowokuqala ukufunda inkqubo yokuguqula isinyithi ezahlukahlukeneyo, ezifana nelothe, kwiimeko ze powdery.

Nangona kunjalo, ngo-1827, esinye isazi saseRashiya uPeter G. Sobolevsky sabonisa indlela entsha yokwenza ubucwebe kunye nezinye izinto ezinomgubo. Ekuqaleni kwenkulungwane yamashumi amabini, ihlabathi latshintsha. Ubuchwepheshe be-metallurgy busetyenziswa, kwaye ngophuhliso lwe-elektroniki, inzala yanda. Emva kwenkulungwane yama-21, iimveliso eziveliswa yi powder metallurgy zanda kakhulu.

1.3Izixhobo eziza kwenziwa ngomgubo wesinyithi

Njengoko besesitshilo ngaphambili, i-metallurgy engumgubo ifanelekile ukwenza ezo mveliso ziya kuxabisa kakhulu ngenye inkqubo okanye zizodwa kwaye zinokwenziwa kuphela ngomgubo wesinyithi. Kule nxalenye, siza kuthetha ngezi zixhobo ngokweenkcukacha.

A.Izixhobo ezixabisa kakhulu ngenye inkqubo

Amalungu olwakhiwo kunye nemathiriyeli ye-porous zizinto ezibiza kakhulu ngezinye iindlela. Amalungu esakhiwo aquka ezinye iintsimbi, ezifana nobhedu, ubhedu, ubhedu, i-aluminiyam, njalo njalo. Zisenokwenziwa ngezinye iindlela. Nangona kunjalo, abantu bathanda ukwenza umgubo wesinyithi ngenxa yexabiso eliphantsi. Izixhobo zePorous ezifana nokugcina ioliiibheringi zihlala zenziwe ngumgubo wesinyithi. Ngale ndlela, ukusebenzisa i-powder metallurgy kunokunciphisa iindleko zokuqala.

B.Izinto ezikhethekileyo ezinokwenziwa kuphela ngomgubo wesinyithi

Kukho iindidi ezimbini zemathiriyeli eyodwa engenakwenziwa ngezinye iindlela. Ziyintsimbi eziphikisayo kunye nezixhobo ezidibeneyo.

Iintsimbi ezizimelayo zineendawo eziphezulu zokunyibilika kwaye kunzima ukuvelisa ngokunyibilika nokuphosa. Uninzi lwezi zinyithi zikwatyumke. I-Tungsten, i-molybdenum, i-niobium, i-tantalum, kunye ne-rhenium yezezi zinyithi.

Ngokubhekiselele kwizinto ezidibeneyo, kukho izinto ezahlukeneyo, ezifana nezixhobo zoqhagamshelwano zombane, isinyithi esinzima, izinto ezixubeneyo, izixhobo zokusika idayimane, iimveliso ezininzi ezenziweyo, i-composite ethambileyo yamagnetic, njalo njalo. Ezi ngxube zesinyithi ezimbini okanye ngaphezulu azinyibiliki, kwaye ezinye iintsimbi zineendawo eziphezulu zokunyibilika.

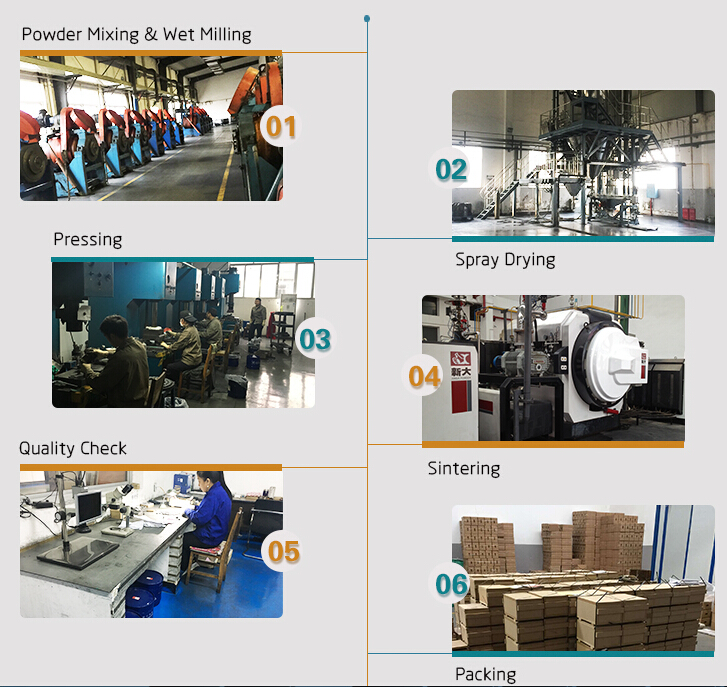

1.4Inkqubo yokuvelisa ngomgubo wesinyithi

Eyona nkqubo yokuvelisa kwimetalurgy engumgubo kukuxuba, ukuhlanganisa, kunye nokuntywila.

1.4.1 Hlanganisa

Xuba umgubo wesinyithi okanye umgubo. Le nkqubo iqhutyelwa kumatshini wokugaya ibhola kunye nentsimbi ye-binder.

1.4.2 Iyahambelana

Layisha umxube kwi-die okanye isikhunta kwaye usebenzise uxinzelelo. Kule nkqubo, ii-compact zibizwa ngokuba yi-green tungsten carbide, oku kuthetha ukuba i-tungsten carbide engafakwanga.

1.4.3 Umshicileli

Fudumeza i-tungsten carbide eluhlaza kwindawo ekhuselayo kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika yamacandelo aphambili ukwenzela ukuba amasuntswana omgubo adityaniswe kunye kwaye anike amandla okwaneleyo kwinto ekujoliswe kuyo. Oku kubizwa ngokuba sintering.

2.Tungsten carbide

2.1Intshayelelo emfutshane yetungsten carbide

I-tungsten carbide, ekwabizwa ngokuba yi-tungsten alloy, i-alloy eqinile, isinyithi esiqinileyo, okanye i-carbide enesamente, yenye yezona zixhobo zinzima emhlabeni, kuphela emva kwedayimani. Njengomxube we-tungsten kunye nekhabhoni, i-tungsten carbide izuza njengelifa lezinto ezimbini eziluhlaza. Ineempawu ezininzi ezintle ezinjengokuqina okuphezulu, ukomelela okuhle, ukumelana nokunxiba, ukuxhathisa impembelelo, ukumelana nokothuka, ukuqina, njalo njalo. Amabanga anokuba yinxalenye yokuchaphazela ukusebenza kwe-tungsten carbide ngokwayo. Zininzi ii-grads series, ezifana neYG, YW, YK, njalo njalo. Olu luhlu lwebakala luhluke kwi-binder powder eyongezwe kwi-tungsten carbide. YG series tungsten carbide ikhetha icobalt njengesibophelelo sayo, ngelixa i-YK series tungsten carbide isebenzisa i-nickel njengesibophelelo sayo.

Ngoncedo oluninzi olugxile kolu hlobo lwezixhobo zesixhobo, i-tungsten carbide inosetyenziso olubanzi. I-tungsten carbide inokwenziwa kwiindidi ezininzi zeemveliso, kubandakanya amaqhosha e-tungsten carbide, i-tungsten carbide rods, tungsten carbide plates, tungsten carbide end Mills, tungsten carbide burrs, tungsten carbide blades, tungsten carbide punch pins, tungsten carbide welding, composite welding kwi. Zingasetyenziswa ngokubanzi njengenxalenye yemingxuma yokugrumba itonela, ukugrumba, kunye nemigodi. Kwaye zingasetyenziswa njengesixhobo sokusika ukwenza ukusika, ukugaya, ukujika, ukugoba, njalo njalo. Ngaphandle kwesicelo soshishino, i-tungsten carbide ingasetyenziselwa kubomi bemihla ngemihla, njengebhola elincinci kwi-nib yepeni ye-gel.

2.2 Izizathu zokusetyenziswa komgubo wesinyithi

I-Tungsten carbide yintsimbi ephikisayo, ngoko ke kunzima ukucubungula ngeendlela eziqhelekileyo zokuvelisa. I-Tungsten carbide yinto enokwenziwa kuphela ngomgubo wesinyithi. Ngaphandle kwetungsten carbide, iimveliso zetungsten carbide zikwanazo nezinye iintsimbi, ezifana necobalt, nickel, titanium, okanye tantalum. Zixutywe, zixinzelelwe yi-molds, kwaye zifakwe kwi-sintered kumaqondo aphezulu. I-Tungsten carbide inendawo ephezulu yokunyibilika, kwaye kufuneka ifakwe kwiqondo lokushisa eliphezulu le-2000鈩?

2.3 Inkqubo yokuvelisa i-tungsten carbide

Kumzi-mveliso, sisebenzisa i-metallurgy yomgubo ukwenza iimveliso ze-tungsten carbide.Eyona nkqubo iphambili ye-metallurgy yomgubo kukuxuba umgubo, i-compact powders, kunye ne-sinter compacts eluhlaza. Ukuqwalasela iimpawu ezikhethekileyo ze-tungsten carbide esiye sathetha ngazo kwi-2.1 Intshayelelo emfutshane kwi-tungsten carbide, inkqubo yokuvelisa i-tungsten carbide inzima kakhulu. Iinkcukacha zezi zilandelayo:

2.3.1 Ukuxuba

Ngexesha lokuxuba, abasebenzi baya kuxuba i-tungsten carbide powder ephezulu kunye ne-binder powder eyona nto i-cobalt okanye i-nickel powder, kwinqanaba elithile. Umlinganiselo umiselwa ngokwebakala abathengi abalifunayo. Ngokomzekelo, kukho i-8% ye-cobalt powder kwi-YG8 tungsten carbide. Umgubo wokubopha ohlukeneyo uneenzuzo ezahlukeneyo. Njengowona uqhelekileyo, i-cobalt iyakwazi ukumanzisa iincinci ze-tungsten carbide kwaye zibophe kakhulu. Nangona kunjalo, ixabiso le-cobalt liyenyuka, kwaye isinyithi se-cobalt siyanda. Ezinye iintsimbi ezimbini ezibophayo ziyi-nickel kunye nentsimbi. Iimveliso ze-tungsten carbide ezinomgubo wentsimbi njengesibophelelo zinamandla angaphantsi koomatshini kunomgubo wecobalt. Ngamanye amaxesha, iifektri ziya kusebenzisa i-nickel njengendawo ye-cobalt, kodwa iipropathi zeemveliso ze-tungsten carbide-nickel ziya kuba ngaphantsi kweemveliso ze-tungsten carbide-cobalt.

2.3.2 Ukusila okumanzi

Imixube ifakwe kumatshini wokugaya ibhola, apho kukho i-tungsten carbide liners okanye i-stainless steel liners. Ngexesha lokugaya okumanzi, i-ethanol kunye namanzi zongezwa. Ubungakanani beengqolowa ze-tungsten carbide particles buya kuchaphazela iipropati zeemveliso zokugqibela. Ngokubanzi, i-tungsten carbide enobungakanani obuziinkozo obukhulu iya kuba nobunzima obuphantsi.

Emva kokugaya okumanzi, umxube we-slurry uya kugalelwa kwisitya emva kwe-sieving, eyona nto ibalulekileyo yokuthintela i-tungsten carbide ekungcoleni. I-slurry tungsten carbide igcinwe kwisitya ukuze ilinde amanyathelo alandelayo.

2.3.3 Isitshizi esomileyo

Le nkqubo kukukhupha amanzi kunye ne-ethanol kwi-tungsten carbide kwaye yomise umxube we-tungsten carbide powder kwi-spray drying tower. Iigesi ezintle zongezwa kwinqaba yokutshiza. Ukuqinisekisa umgangatho we-tungsten carbide yokugqibela, i-liquid kwi-tungsten carbide kufuneka yomiswe ngokupheleleyo.

2.3.4 Ukuhluza

Emva kokutshiza okomileyo, abasebenzi baya kuhluza i-tungsten carbide powder ukuze basuse amaqhuma e-oxidation anokwenzeka, okuya kuchaphazela ukudibanisa kunye ne-sintering ye-tungsten carbide.

2.3.5 Ukuhlanganisa

Ngexesha lokudibanisa, umsebenzi uya kusebenzisa oomatshini ukuvelisa i-tungsten carbide i-compact compacts eluhlaza ngobukhulu obuhlukeneyo kunye nemilo ngokwemizobo. Ngokuqhelekileyo, i-compact compacts eluhlaza icinezelwe ngoomatshini abazenzekelayo. Ezinye iimveliso zahlukile. Ngokomzekelo, iintonga ze-tungsten ze-carbide zenziwe ngoomatshini be-extrusion okanye oomatshini be-sostatic bag-bag. Ubungakanani beengqungquthela eziluhlaza bukhulu kunemveliso yokugqibela ye-tungsten carbide, njengoko i-compacts iya kuncipha kwi-sintering. Ngexesha lokudibanisa, ezinye ii-agent ezenza izinto ezifana ne-wax yeparafini ziya kongezwa ukuze kufumaneke i-compacts elindelekileyo.

2.3.6 Ukucula

Kubonakala ngathi i-sintering yinkqubo elula kuba abasebenzi kufuneka babeke kuphela i-compacts eluhlaza kwisithando somlilo. Enyanisweni, ukucula kuntsonkothile, kwaye kukho izigaba ezine ngexesha lokucula. Zikukususwa kwe-arhente yokubumba kunye nenqanaba lokutshisa kwangaphambili, isigaba esiqinileyo se-sintering, isigaba solwelo se-sintering, kunye nenqanaba lokupholisa. Iimveliso ze-tungsten carbide ziyancipha kakhulu ngexesha lesigaba esiqinileyo se-sintering.

Kwi-sintering, ubushushu kufuneka bunyuke ngokuthe ngcembe, kwaye iqondo lobushushu liya kufikelela kwincopho yalo kwinqanaba lesithathu, inqanaba lesigaba solwelo. Indawo ye-sintering kufuneka icoceke kakhulu. Iimveliso ze-tungsten carbide ziya kuncipha kakhulu ngeli xesha.

2.3.7 UkuJonga okokugqibela

Ngaphambi kokuba abasebenzi bapakishe iimveliso ze-tungsten carbide kwaye bazithumele kubathengi, yonke into enye yemveliso ye-tungsten carbide kufuneka ihlolwe ngononophelo. Izixhobo ezahlukeneyo kwiilabhoratriiya kusetyenziswa kule nkqubo, njenge-Rockwell hardness tester, i-metallurgical microscope, i-density tester, i-coercimeter, njalo njalo. Umgangatho wabo kunye neempawu, ezifana nobunzima, ubuninzi, isakhiwo sangaphakathi, isixa se-cobalt, kunye nezinye iimpawu, kufuneka zihlolwe kwaye ziqinisekiswe.

3.Summary

Njengesixhobo esithandwayo nesisetyenziswa ngokubanzi, i-tungsten carbide inemarike ebanzi kushishino lokuvelisa. Njengoko sithethile ngasentla, i-tungsten carbide inendawo ephezulu yokunyibilika. Kwaye iyimbumba ye-tungsten, ikhabhoni, kunye nezinye iintsimbi, ngoko ke i-tungsten carbide kunzima ukuyivelisa ngezinye iindlela zemveli. I-powder metallurgy amadoda indima ebalulekileyo ekwenzeni iimveliso ze-tungsten carbide. Ngomgubo we-metallurgy, iimveliso ze-tungsten carbide zifumana iipropati ezahlukeneyo emva koluhlu lwenkqubo yokuvelisa. Ezi zakhiwo, ezinjengokuqina, amandla, ukumelana nokunxiba, ukumelana nokugqwala, njalo njalo, zenze i-tungsten carbide isetyenziswe ngokubanzi kwimigodi, ukusika, ukwakhiwa, amandla, ukuvelisa, umkhosi, i-aerospace, njalo njalo.

I-ZZBETTER izinikele ekuveliseni umgangatho wehlabathi kunye neemveliso ze-tungsten carbide ezikumgangatho ophezulu. Iimveliso zethu zithengiswe kumazwe amaninzi nakwiindawo kwaye zenza impumelelo enkulu kwimarike yasekhaya. Senza iimveliso ezahlukeneyo ze-tungsten carbide, kubandakanya i-tungsten carbide rod, amaqhosha e-tungsten carbide, i-tungsten carbide iyafa, ii-tungsten carbide blades, i-tungsten carbide rotary burrs, njalo njalo. Iimveliso ezenzelwe wena nazo ziyafumaneka.

Ukuba unomdla kwiimveliso ze-tungsten carbide kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, ungaQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL emazantsi ephepha.