Uyilo kunye nokuSetyenziswa kweSixhobo sokuTshintsha ngokuKhawulezayo iStuds kuMphezulu weHPGR Roller

Uyilo kunye nokuSetyenziswa kwesiXhobo sokuTshintsha ngokuKhawulezayo i-Studs kuMphezulu weHPGR Roller

Amagama aPhambili: HPGR; umphezulu we-roller ene-studded; isixhobo sokutshintsha i-stud; indawo yokunyanzela; indawo yoxinzelelo; uvavanyo lweBrazing;

Ukusombulula ubunzima ekutshintsheni i-studs ebusweni be-roller ye-HPGR, isixhobo sokutshintsha ngokukhawuleza i-studs senziwe, kwaye indlela yokutshintsha i-studs yaziswa. Isixhobo sibonakaliswe ngokusebenza okulula, ukusetyenziswa ngokuphindaphindiweyo, ixesha elifutshane lokutshintshwa, kunye nobomi benkonzo ende. Inokunciphisa ukugcinwa kwezixhobo kunye neendleko zokulungisa kunye nexesha, kunye nokukhusela ngokufanelekileyo umkhono we-roller. Ukunciphisa izinga lokunxiba kunye nokwandisa ubomi benkonzo.

Ngenxa yokuba i-stud ifakwe kwi-stud emngxunyeni kusetyenziswa i-gap ehambelana ne-binder, umkhono we-stud othambileyo uya kukhubazeka emva kokuphuma emva kwexesha lokusetyenziswa, kwaye isikhonkwane esaphukileyo esiveziweyo somkhono we-roller silinganiselwe, kunye nezinye izikhonkwane. iqhekeza ngaphakathi komkhono we-roller. Ngenxa yokuba akukho mandla okuqhawula i-stud ephukileyo, kunzima kakhulu ukutshintsha i-stud ephukileyo. Nangona i-agent edibeneyo ihluleka ngokufudumeza, i-stud isenzima ukuyikhupha. Ngoko ke, kubaluleke kakhulu ukuphuhlisa isixhobo sokutshintsha ngokukhawuleza kwi-roller face studs ukwandisa ubomi bobuso be-roller.

Imigaqo yokutshintsha i-studs:

Imingxunya ye-stud kunye ne-stud iqiniswa kwaye ilungiswe ngokunamathela. Ekubeni i-adhesive iya kuphumelela emva kokufudumeza kwiqondo lokushisa elithile, i-adhesive inokukhutshazwa ngokufudumeza i-stud kwaye emva koko i-stud eyonakalisiweyo ikhutshwe ngokudweba. Nangona kunjalo, ngenxa yokuba inxalenye eshiyekileyo ye-stud idla ngokungcwatywa emngxunyeni we-stud xa yaphukile, kunzima ukuthwala amandla, ngoko ke kuyimfuneko ukutshisa indawo yoxinzelelo kwi-residual studs nge-welding.

Uvavanyo lweWelding:

Kwinkqubo yokuthatha isikhonkwane esiphukileyo, kuyimfuneko ukudibanisa i-stud kunye nesixhobo sokutshintsha izikhonkwane kunye namandla athile. Ngenxa yokuba i-stud is cemented carbide, kunzima ukudibanisa kunye ne-welding material, ngoko ke ukukhetha indlela efanelekileyo ye-welding kunye ne-welding material iba sisitshixo sokutsala ii-studs. Ukoyisa ingxaki yoxinzelelo lwe-welding kwinkqubo yokutshintshwa kwe-stud, iimvavanyo ze-welding ze-carbide studs zenziwe nge-arc welding kunye ne-brazing ngokulandelanayo.

Uvavanyo lweBrazing:

Uvavanyo lwe-welding point yoxinzelelo lwenziwa ngokuqhafaza, kwaye izinto ezisisiseko zaziyintsimbi eqhelekileyo. Emva kwe-welding, akukho ngqungquthela kwi-stud kunye nesiseko sentsimbi ye-welding joint eqinile (jonga uMfanekiso 1), ngoko ke, kufanelekile ukusebenzisa indlela yokuqhawula ukudibanisa indawo yoxinzelelo kunye nokudibanisa i-stud kunye nesixhobo sokutshintsha izikhonkwane. .

Ukucombulula ubunzima bokutshintsha indawo yesilivere yobuso bomatshini wokusila woxinzelelo oluphezulu, eli phepha libonelela ngesixhobo sokutshintsha ngokukhawuleza kwi-roller face stud ye-high-pressure roller grinding machine.

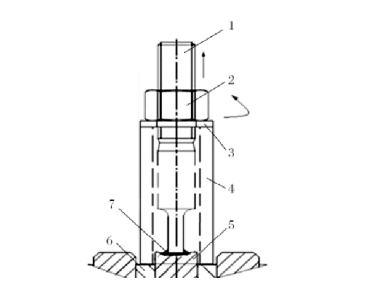

Njengoko kubonisiwe kuMfanekiso 2, isixhobo siquka i-screw yokudibanisa, i-nut, i-washer flat, kunye nombhobho wensimbi. Esinye isiphelo se-screw yokudibanisa sifakwe kwi-threaded, kwaye i-diameter ye-nominal kufuneka ibe mkhulu kunobubanzi be-stud, ukuphepha ukuphazamiseka kombhobho wensimbi xa ukhupha i-stud. Esinye isiphelo asikho intambo, kwaye ububanzi buncinci kune-stud, ekulungele ukuthungwa okulandelayo. I-nut ijikelezwe kwicala lemisonto kwaye ifakwe kunye ne-washer flat. Xa i-stud eyaphukileyo kunye ne-screw ye-lead zidityanisiwe kunye, i-nut isetyenziselwa ukujiya i-screw ye-lead yokudibanisa kwaye inike i-stud i-axial tension egudileyo; Umbhobho wentsimbi ugqunywe kwicala elingenamisonto, kwaye i-screw yokudibanisa ibonakaliswe.

Umfanekiso we-2 Uvavanyo lwe-welding ye-Brazing

1.Isikrufu sokudibanisa 2. Nut 3. Iwasha eflethi 4. Umbhobho wentsimbi 5.Stud 6. Umkhono 7.Indawo yokuwelda

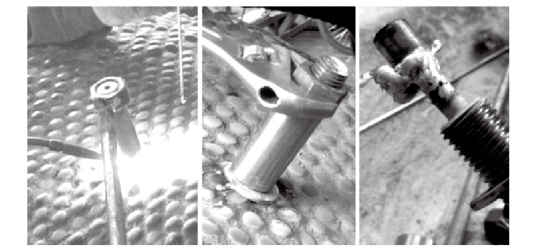

Uvavanyo:

Njengoko kubonisiwe kuMfanekiso 3, i-stud extruding roll eshiyiweyo yayisetyenziselwa ukwenza uvavanyo. Isiphelo somsonto wesixhobo sokutshintsha isikhonkwane sasidityaniswe kwi-stud kwi-roll surface, kwaye i-stud ingasuswa ngempumelelo ngokuguqula i-nut nge-wrench.

Umzobo.3 Ubume kunye nomgaqo wokusebenza wesixhobo sokutshintsha i-stud

Fig.4 Uvavanyo lokutshintshwa kwestud

Ukuba unomdla kwi-CARBIDE STUDS kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, UNGAQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL emazantsi ephepha.