I-Carbide Rotary Burr ene-Single-cut

I-Carbide Rotary Burr ene-Single-cut

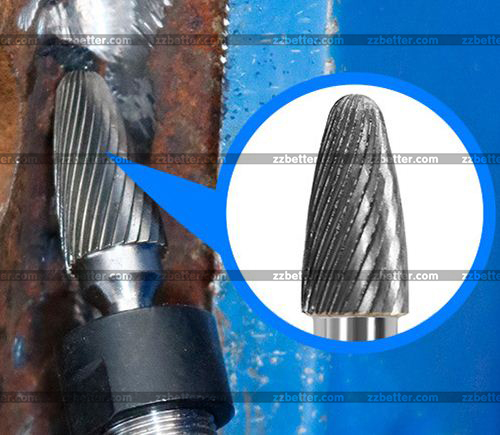

Ipateni yezinyo ye-tungsten carbide rotary burrs kufuneka ikhethwe ngokweempawu zezinto zokusebenza eziza kucutshungulwa. Xa ufaka i-aluminium, ubhedu, intsimbi ethambileyo, kunye nezinye izinto ezithambileyo, izinyo elinye (amazinyo okugaya) i-carbide burr lolona khetho lungcono. Ifayile yepateni yezinyo enye ine-angle enkulu yangaphambili, i-angle ye-wedge encinci, i-chip enkulu ephethe i-groove, i-hard chip blocking, kunye ne-edge yokusika ebukhali.

Emva kokwazi iindlela kunye nemigaqo yokukhetha umgangatho ophezulu we-tungsten carbide rotary burr, kufuneka siqonde ukusetyenziswa kwayo kunye nenzuzo. I-cemented carbide rotary burr sisixhobo esibalulekileyo ekusetyenzweni kwamashishini, kwaye sisixhobo esithandwayo kubathandi bobugcisa. Njengamazinyo oshishino, i-carbide rotary burr enesamente igubungela izibonelelo ezahlukeneyo kwaye isetyenziswa ngokubanzi kumasimi amaninzi.

1. Iyakwazi ukucubungula intsimbi, intsimbi, intsimbi yekhabhoni, insimbi ye-alloy, insimbi engenasici, ubhedu, i-aluminiyam, i-marble, i-jade, ithambo kunye ne-non-metallic. Ukucutshungulwa kokuqina kunokufikelela kwi-HRA ≥ 85.

2. Inokutshintsha ivili elincinane lokusila ngesiphatho ngaphandle kongcoliseko lothuli.

3. Ukusebenza kakuhle kwemveliso. Ukucutshungulwa kobuchule kuphezulu ngokuphindwe kashumi kunolo lwebhula yesandla kwaye phantse ngokuphindwe kashumi ngaphezulu kwevili elincinane lokusila elinesiphatho.

4. Umgangatho wokuqhuba kakuhle kunye nokugqiba okuphezulu. Iyakwazi ukucubungula zonke iintlobo zemingxuma yokungunda echanekileyo.

5. Ubomi benkonzo ende. Ukuqina kwayo kumaxesha angama-10 aphezulu kuneso sixhobo sensimbi esinesantya esiphezulu kunye namaxesha angama-200 aphezulu kunelo livili elincinane lokugaya.

6. Kulula ukuyiqonda, kulula ukuyisebenzisa, ikhuselekile kwaye inokuthenjwa.

7. Inkqubo ebanzi inokunciphisa amaxesha amaninzi.

I-ZZbetter ikhethekileyo ekuveliseni ii-burrs ezijikelezayo ze-carbide iminyaka emininzi ukuvelisa ii-tungsten carbide burrs ezifakwe kwi-CNC yezixhobo zokuvelisa ezizenzekelayo kwaye zisetyenziswe kwimodi yolawulo lwangoku. Umgangatho wemveliso uhlolwe kuwo onke amanqanaba. Umgangatho wazo zonke iimveliso zodlula lowo wamashishini afanayo. Ke ngoko, inconywa kakhulu luninzi lwabasebenzisi.

Ngolwazi oluthe kratya, nceda uqhagamshelane nathi ngenombolo yefowuni okanye i-imeyile ngasekhohlo okanye Sithumele i-imeyile emazantsi ephepha.