Isigama se-alloy eqinile (1)

Isigama se-alloy eqinile (1)

Ukukhuthaza ukuqonda kweengxelo kunye nemibhalo yobugcisa malunga ne-alloy enzima, ukulungelelanisa isigama, kwaye uchaze intsingiselo yamagama obugcisa kumanqaku, silapha ukuze sifunde imimiselo ye-alloy enzima.

ITungsten Carbide

I-Tungsten carbide ibhekiselele kwii-composites ezixutyiweyo ezibandakanya i-carbides yentsimbi ephikisayo kunye nezibophelelo zetsimbi. Phakathi kweentsimbi zentsimbi ezisetyenziswayo ngoku, i-tungsten carbide (WC), i-titanium carbide (TiC), kunye ne-tantalum carbide (TaC) zizinto eziqhelekileyo. Isinyithi se-cobalt sisetyenziswa ngokubanzi kwimveliso ye-carbide enesamente njengesibophelelo. Kwezinye izicelo ezikhethekileyo, izibophelelo zentsimbi ezifana ne-nickel (Ni) kunye ne-iron (Fe) nazo zingasetyenziswa.

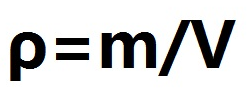

Ukuxinana

Uxinaniso lubhekisa kumlinganiselo wobunzima ukuya kumthamo wemathiriyeli, ekwabizwa ngokuba ngumxhuzulane okhethekileyo. Umthamo wayo nawo uqulethe umthamo we-pores kwizinto eziphathekayo. I-Tungsten carbide (WC) inoxinano lwe-15.7 g/cm³ kunye ne-cobalt (Co) inoxinano lwe-8.9 g/cm³. Ngoko ke, njengoko umxholo we-cobalt (Co) kwi-tungsten-cobalt alloys (WC-Co) iyancipha, ukuxinana ngokubanzi kuya kwanda. Nangona ubuninzi be-titanium carbide (i-TiC) bungaphantsi kwe-tungsten carbide, kuphela i-4.9 g / cm3. Ukuba i-TiC okanye ezinye izinto ezincinci eziphantsi zongezwa, ubuninzi obupheleleyo buya kuncipha. Ngokuqulunqwa kweekhemikhali ezithile zezinto eziphathekayo, ukunyuka kwama-pores kwizinto eziphathekayo kubangela ukuhla kobuninzi.

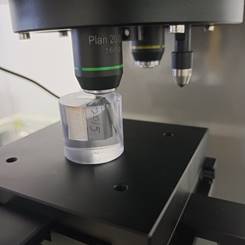

Ukuqina

Ukuqina kubhekisa kwisakhono semathiriyeli ukuxhathisa ukonakala kweplastiki.

Vickers hardness (HV) isetyenziswa kakhulu kumazwe ngamazwe. Le ndlela yokulinganisa ubulukhuni ibhekisela kwixabiso lobunzima obufunyenwe ngokusebenzisa idayimani ukungena kumphezulu wesampuli ukulinganisa ubungakanani bokuhamba phantsi komthwalo othile womthwalo. Ukuqina kwe-Rockwell (HRA) yenye indlela yokulinganisa ubulukhuni esetyenziswa ngokuqhelekileyo. Isebenzisa ubunzulu bokungena kwekhowuni yedayimane eqhelekileyo ukulinganisa ubulukhuni. Bobabini ubunzima beVickers kunye nobunzima be-Rockwell bunokusetyenziselwa ukulinganisa ubulukhuni be-carbide ene-cemented, kwaye ezi zimbini zinokuguqulwa zibe enye kwenye.

Ukugoba amandla

Amandla okugoba kwaziwa njengamandla ophukayo anqamlezayo okanye ukomelela okuguquguqukayo. I-alloys enzima yongezwa njengento elula yokuxhasa i-pivots ezimbini, kwaye emva koko umthwalo usetyenziswa kwi-centerline yazo zombini ii-pivots de kube i-alloy enzima igqabhuka. Amaxabiso abalwe kwifomyula yokuphefumula asetyenziselwa umthwalo ofunekayo ukuphuka, kunye nommandla we-cross-sectional wesampuli. Kwi-tungsten-cobalt alloys (WC-Co), amandla okuguquguquka ayanda kunye nomxholo we-cobalt (Co) kwi-alloys ye-tungsten-cobalt, kodwa amandla e-flexural afikelela kwinqanaba eliphezulu xa umxholo we-cobalt (Co) ufikelela malunga ne-15%. Amandla e-Flexural alinganiswa nge-avareji yemilinganiselo emininzi. Eli xabiso liya kuhluka kunye nejometri yesampuli, imeko yendawo (ubushelelezi), uxinzelelo lwangaphakathi, kunye neziphene zangaphakathi zezinto. Ngoko ke, amandla okuguquguquka kuphela amandla anamandla, kwaye amaxabiso anamandla aguquguqukayo awakwazi ukusetyenziswa njengesiseko sokukhethwa kwezinto eziphathekayo.

I-Porosity

I-carbide enesamente iveliswa yinkqubo yesinyithi somgubo ngokucofa kunye nokuntywila. Ngenxa yobume bendlela, umkhondo we-porosity unokuhlala kwisakhiwo se-metallurgical yemveliso.

Ukunciphisa i-porosity kunokuphucula ngokufanelekileyo ukusebenza ngokubanzi kwemveliso. Inkqubo ye-pressure sintering yindlela esebenzayo yokunciphisa i-porosity.