Umahluko phakathi kweTungsten Carbide kunye nezixhobo zokusika zeHSS

Umahluko phakathi kweTungsten Carbide kunye neHSS Cutting Tools

Ukongeza kwizinto ze-tungsten carbide, izixhobo zokusika zinokuphinda ziveliswe ngezinto zetsimbi ezikhawulezayo. Nangona kunjalo, ngenxa yeendlela ezahlukeneyo zeekhemikhali kunye neendlela zokuvelisa i-tungsten carbide kunye nentsimbi yesantya esiphezulu, umgangatho wezixhobo zokusika ezilungiselelwe nazo zihluke.

1. Iimpawu zeMichiza

Insimbi enesantya esiphezulu, ekwabizwa ngokuba yintsimbi yesixhobo esinesantya esiphezulu okanye intsimbi yangaphambili, ngokuqhelekileyo ibizwa ngokuba yiHSS, ezona nxalenye zeekhemikhali eziphambili yikhabhoni, isilicon, imanganese, iphosphorus, isulfure, ichromium, molybdenum, nickel, kunye netungsten. Inzuzo yokongeza i-tungsten kunye ne-chromium kwintsimbi yangaphambili kukuphucula ukuthomalalisa ukuchasana kwemveliso xa ishushu, ngoko kwandisa isantya sayo sokusika.

I-Tungsten carbide, ekwabizwa ngokuba yi-cemented carbide, yimathiriyeli ye-alloy esekwe kwi-refractory metal complex compounds kunye nesinyithi njengesibophelelo. Iikhompawundi ezinzima eziqhelekileyo ziyi-tungsten carbide, i-cobalt carbide, i-niobium carbide, i-titanium carbide, i-tantalum carbide, njl., kunye nezibophelelo eziqhelekileyo ziyi-cobalt, i-nickel, isinyithi, i-titanium, njl.

2. Iimpawu zomzimba

Amandla e-flexural yenjongo yentsimbi yesantya esiphezulu yi-3.0-3.4 GPa, ukuqina kwempembelelo yi-0.18-0.32 MJ / m2, kwaye ubunzima buyi-62-65 HRC (xa ubushushu buphakama ukuya kwi-600 ° C ukuba ubunzima buya kuba. 48.5 HRC). Inokubonwa ukuba intsimbi enesantya esiphezulu ineempawu zamandla alungileyo, ukumelana nokunxiba kakuhle, ukumelana nobushushu obuphakathi, kunye ne-thermoplasticity engalunganga. Ngokuqinisekileyo, izibonakaliso ezithile zokusebenza zentsimbi ephezulu zihambelana ngokusondeleyo nokwakheka kweekhemikhali kunye nomlinganiselo wezinto eziluhlaza.

Amandla oxinzelelo lwe-tungsten carbide esetyenziswa ngokuqhelekileyo yi-6000 MPa kunye nobunzima yi-69 ~ 81 HRC. Xa iqondo lobushushu linyuka ukuya kwi-900 ~ 1000℃, ukuqina kusenokugcinwa malunga ne-60 HRC. Ukongeza, inamandla alungileyo, ukuqina, ukuxhathisa ukunxiba, ukumelana nobushushu, kunye nokumelana nomhlwa. Nangona kunjalo, izibonakaliso ezithile zokusebenza ze-carbide ene-cemented zihambelana ngokusondeleyo nokwakheka kweekhemikhali kunye nomlinganiselo wezinto eziluhlaza.

3. Inkqubo yokuvelisa

Inkqubo yokuvelisa intsimbi enesantya esiphezulu ngokuqhelekileyo: ukunyibilikiswa kwesithando somlilo rhoqo, ukucocwa ngaphandle kwesithando somlilo, ukucocwa kwe-vacuum degassing, ukunyibilikisa i-electro slag, umatshini wokubumba okhawulezayo, isando sokwenza, ukuchaneka komatshini, ukuqengqeleka okushushu kwiimveliso, ipleyiti kunye nomzobo. kwiimveliso.

Inkqubo yokuvelisa i-tungsten carbide ngokubanzi: ukuxuba, ukugawula okumanzi, ukomisa, ukucinezela, kunye ne-sintering.

4. Ukusetyenziswa

Intsimbi enesantya esiphezulu isetyenziswa ikakhulu ukwenza izixhobo zokusika (ezifana nedrili, iimpompo, iibhleyidi zeesarha) kunye nezixhobo ezichanekileyo (ezinje ngeehobs, iigear shapers, kunye neebroaches).

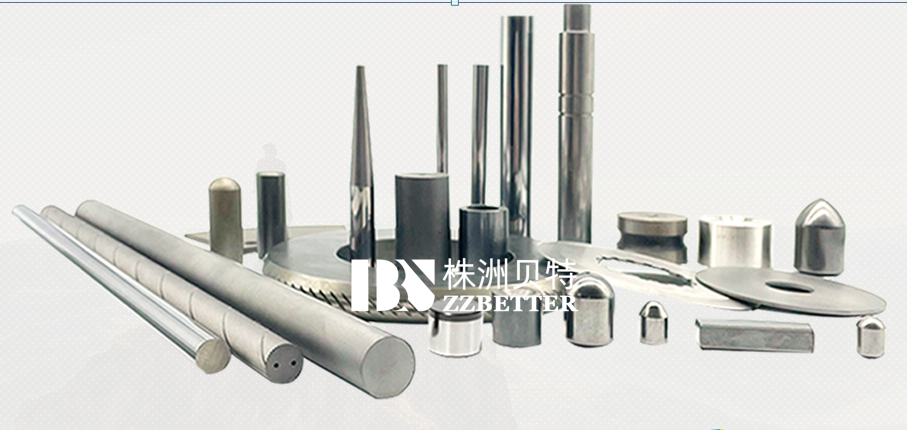

Ngaphandle kwezixhobo zokusika i-tungsten carbide iphinda isetyenziswe ukwenza imigodi, ukulinganisa, ukubumba, ukuxhathisa ukunxiba, ukushisa okuphezulu, njl njl izixhobo ngokunjalo.

Ubukhulu becala phantsi kweemeko ezifanayo, isantya sokusika izixhobo ze-tungsten carbide zi-4 ukuya kwi-7 amaxesha aphakamileyo ngaphezu kwe-speed-speed steel, kwaye ubomi bu-5 ukuya kuma-80 amaxesha aphezulu.

Ukuba unomdla kwiimveliso ze-tungsten carbide kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, ungaQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL emazantsi ephepha.