Itekhnoloji yeMveliso yeHard Alloy

Itekhnoloji yeMveliso yeHard Alloy

I-alloy eqinileluhlobo lwemathiriyeli eqinileyo eyenziwe ngentsimbi enqabileyo eqinileyo kunye nentsimbi edibeneyo; i-alloys enzima, zizinto ezinzima ezinokumelana nokunxiba okuphezulu kunye nokuqina, eziveliswa ngumgubo we-metallurgy; ngenxa yokusebenza kwayo okugqwesileyo, i-carbide enesamente isetyenziswa ngokubanzi kumatshini, iindawo ezingagugiyo, imigodi, ukugrumba i-geological, imigodi yeoli, iinxalenye zoomatshini kunye nezinye iindawo.

ITekhnoloji yeMveliso yeeMetals ezilukhuni ijongana neteknoloji yemveliso kunye nophando lwesakhiwo kunye neempawu ezibonakalayo zomatshini wesinyithi esiqinileyo. Enye yezinto ezibalulekileyo kwinkqubela phambili yobugcisa yimveliso yesizwe yeentsimbi ezinzima. Uphuhliso kunye nokuqaliswa kwesinyithi esiqinileyo esisebenza kakuhle kakhulu siqinisekisa ukuba imveliso yabasebenzi iya kwanda kumsebenzi wesinyithi, imigodi, i-oyile kunye namalahle.

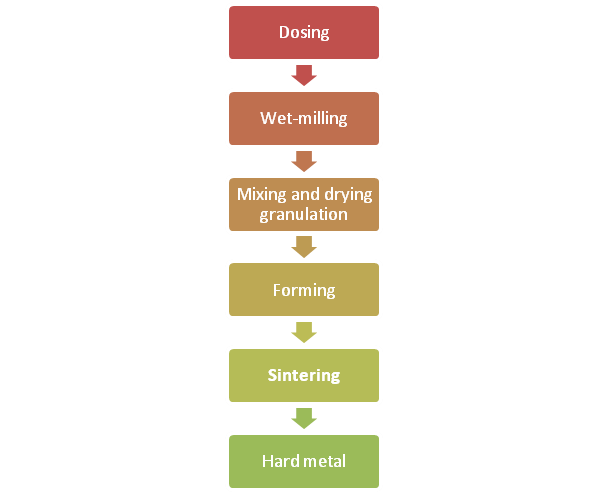

Inkqubo yokuvelisa i-carbide ene-cemented ngolu hlobo lulandelayo: ukulungiswa komxube, ukucinezela kunye nokubumba, i-sintering. Kukho iinkqubo ezi-3 zizonke.

Itshathi equkuqelayo yenkqubo yokuvelisa i-alloy eqinile

Izinto ezisetyenziswayo kunye nenani elincinci lezongezo ezifunekayo zilinganiswe kwaye zilayishwe kwi-rolling ball mill okanye i-mill eshukumisayo. Kwibhola lebhola, izinto eziluhlaza zihlanjululwa kwaye zihanjiswe ngokulinganayo. Emva kokumisa ukutshiza kunye nokuhluzwa kwe-vibration, umxube kunye neemfuneko ezithile zokubunjwa kunye nobukhulu beengqungquthela zenziwa ukuhlangabezana neemfuno zokucofa ukubunjwa kunye ne-sintering. Emva kokucinezela kunye ne-sintering, i-alloy blanks enzima iyakhululwa kwaye ipakishwe emva kokuhlolwa komgangatho.

Iintsimbi eziqinileyo ezingenanto

Indlela yokucubungula i-carbide erhabaxa enesamente:

1. Ukucutshungulwa kwentambo yangaphakathi nangaphandle: i-carbide thread processing kufuneka iqhutywe ngokugaya intambo, ayikwazi ukucutshungulwa ngokuthe ngqo nge-screw taps.

2. Ukucutshungulwa kwe-groove yangaphakathi: intonga yokugaya idayimane kufuneka ikhethwe, kwaye inani lokusika ixesha ngalinye lilawulwa ukuba libe malunga ne-20 ukuya kwi-30 um. Uhlengahlengiso oluthile kufuneka lwenziwe ngokuhambelana neenzuzo kunye nokungonakali kwentonga yokugaya idayimane.

3. I-EDM

4. I-Welding processing: i-brazing, i-welding processing processing

5. Ukucutshungulwa kokugaya: ukugaya okungenaziko, ukugaya kwangaphakathi, ukugaya umphezulu, isixhobo sokusila, ivili lokugaya ngokuqhelekileyo ivili lokugaya idayimane, ukhetho oluthile kuxhomekeke kwiimfuno zenkqubo.

6. I-Laser processing: i-laser cutting forming, i-punching iyafumaneka, kodwa ubukhulu bokusika bunyanzeliswa ngamandla okuthintela umatshini we-laser.

Ukuba imveliso yakho ye-tungsten carbide iba buthuntu okanye "inamafu", akuyomfuneko ukuba uthenge isicoci sezacholo ezibiza kakhulu ukuze kukhanye kwaye kupolishwe ubucwebe bakho betungsten. Umxube olula wamanzi anesepha kunye nelaphu elicocekileyo kuphela kwezinto ozidingayo ukuze ucoce le ntsimbi eqinileyo, ekwaziyo ukumelana nemikrwelo. Kwakhona, i-silicon carbide yeyona nto ilungileyo yokulola i-carbide.

Ukuba unomdla kwiimveliso ze-tungsten carbide kwaye ufuna ulwazi oluninzi kunye neenkcukacha, unakoQHAGAMSHELANA NATHIngefowuni okanye ngeposi ekhohlo, okanyeSITHUMELE imeyileemazantsi eli phepha.