Indlela Owenza Kabuhlungu Ngayo End Mill

Indlela Owenza Kabuhlungu Ngayo End Mill

Iintsimbi zokuphela kweCarbide ziyakwazi ukumelana nobushushu ngokugqithisileyo kwaye zisetyenziselwa izicelo ezinesantya esiphezulu kwezinye zezona zinto zinzima njengentsimbi ekhandiweyo, isinyithi esingeyontsimbi, ialloyi, kunye neeplastiki. Kodwa ngaba uyazi ukuba ubomi benkonzo ye-milling cutter buya kuchaphazeleka ukuba ayisetyenziswanga kakuhle? Nazi ezinye iinkalo ekufuneka uzikhathalele.

1. Wachola ilitye lokusila elingalunganga.

I-Carbide end Mill eneengubo inokunyusa ukuthambisa, kunye nokucotha kwesixhobo sendalo esinxitywayo, ngelixa ezinye zinokonyusa ubulukhuni kunye nokumelana ne-abrasion. Nangona kunjalo, akuzona zonke iingubo ezifanelekileyo kuzo zonke izinto eziphathekayo, kwaye umahluko ubonakala kakhulu kwizinto ezinobuncwane kunye ne-non-ferrous. Umzekelo, i-Aluminium Titanium Nitride (i-AlTiN) yokugquma inyusa ubulukhuni kunye nokumelana nobushushu kwizixhobo ze-ferrous kodwa inobudlelwane obuphezulu kwi-aluminium, ibangela ukunamathela kwesixhobo sokusika kwisixhobo sokusika. Ingubo ye-Titanium Diboride (TiB2), kwelinye icala, inobudlelwane obuphantsi kakhulu kwi-aluminium, inqanda ukwakhiwa komphetho kunye nokupakishwa kwe-chip, kwaye yandisa ubomi besixhobo.

2. Ukusebenzisa ubude obude bokusika ngendlela engafanelekanga.

Nangona ubude obude bokusika buyimfuneko kwimisebenzi ethile, ngakumbi ekugqibeni imisebenzi, kunciphisa ukuqina kunye namandla esixhobo sokusika. Njengomthetho jikelele, ubude besixhobo sokusikwa kufuneka bube bubude obufunekayo ukuze kuqinisekiswe ukuba isixhobo sigcina ubuninzi be-substrate yaso yokuqala kangangoko kunokwenzeka. Okukhona ubude besixhobo sisikiwe, kokukhona sichanabeka ngakumbi ekuphambukeni, nto leyo enciphisa ubomi baso besixhobo esisebenzayo kunye nokwandisa ithuba lokwaphuka.

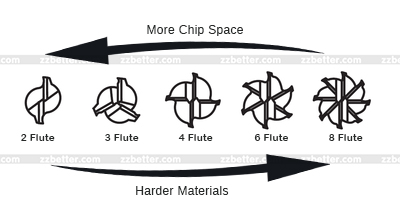

3. Ukukhetha imbande engalunganga.

Ukubalwa kwefluti yesixhobo kunefuthe elithe ngqo nelibonakalayo ekusebenzeni kwayo kunye neeparamitha ezisebenzayo. Nangona kunjalo, ukubala kwefluti ephezulu akusoloko kubhetele. Ubalo lweflute esezantsi luqhele ukusetyenziswa kwi-aluminiyam kunye nezixhobo ezingezizo i-ferrous, ngokuyinxenye ngenxa yokuba ukuthamba kwezi zixhobo kuvumela ukuguquguquka okuthe kratya okunyuka kwamaxabiso okususwa kwesinyithi kodwa nangenxa yeepropathi zeetshiphusi zazo. Izinto ezingezizo ezoni zihlala zivelisa ixesha elide, iitshiphusi zentambo, kunye nokubalwa kweflute esezantsi kunceda ukunciphisa ukusika itshiphu. Izixhobo zokubala zefleyiti eziphakamileyo zihlala ziyimfuneko kwimathiriyeli eyongeziweyo eyongeziweyo, zombini ngokwamandla azo andayo kwaye ngenxa yokuba ukusika itshiphu akuyongxaki kangako kuba ezi mathiriyeli zihlala zivelisa iitshiphusi ezincinci kakhulu.

Sisebenza ngokukhethekileyo ekuboneleleni ngezixhobo ezikumgangatho ophezulu ze-carbide end Mills kunye nenkxaso yenkonzo yonikezelo olukhawulezayo kwihlabathi kwiodolo yakho.

Ukuba unomdla kwi-tungsten carbide end mills kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, ungaQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL emazantsi ephepha.