Iindidi eziNtathu zokuSebenza i-Cemented Carbide Rods

Iindidi eziNtathu zokuSebenzaIintonga zeCarbide ezenziwe ngesamente

Ukubumba yeyona nkqubo ilawulekayo ekuvelisweni kwe-alloy eqinile, kwaye yinkqubo ephambili yokuqinisekisa ukuchaneka kunye nomgangatho obonakalayo we-alloy blanks. Yinkqubo yokudibanisa umgubo ube yinto engenanto kunye nesimo esifunwayo. Iimfuno zayo ezisisiseko kukuba namandla athile kunye nobukhulu obuchaziweyo.

1. Ukubumba ngokuchanekileyo

Ukucofa okuchanekileyo akufuneki kube nehardware elungileyo kuphela, kodwa kunye nesoftware elungileyo. Ngokukodwa, kuyimfuneko ukuba: ucinezele oluchanekileyo oluphezulu (i-TPA press), ukufa okuchanekileyo okuphezulu, umxube wokusebenza okuphezulu, iiparamitha zenkqubo yocinezelo kunye nezinye iimeko ezisisiseko.

Ukucofa okucokisekileyo kubandakanya: ukucinezela umjikelo, ukucinezela umatshini weparamitha yenkqubo kunye nemigangatho yokubala, ukhetho lomxube, ukucofa ukhetho lokufa, ukukhetha izikhephe, kunye nokucinezela umgangatho, kunye nokubuyiswa kwezinto eziphathekayo, njl.

Ucinezela Inkqubo Isazobe↓↓↓

2. Ukwenziwa kwe-Extrusion

Ukubumba i-Extrusion ibeka umxube kwi-cylinder ye-extrusion emva konyango lweplastiki, emva koko ukufakela kufe kwelinye icala le-cylinder ye-extrusion kunye nemingxuma efunwayo kumphezulu wezo zifa. I-extruder ifakwe kwelinye icala le-cylinder ye-extruder. Uxinzelelo lwe-extruder lugqithiswa kwi-extruder ukuya kumxube, odlula kumngxuma wokufa kwaye ube ngumkhiqizo owenziweyo.

Iinzuzo zayo kukuba: ubude bemveliso abukhawulelwanga ngokubanzi, kwaye ubuninzi bexesha elide bufana kakhulu. Ngeli xesha, idla ngokuba nemveliso eqhubekayo, ukusebenza kakuhle okuphezulu kunye nezixhobo ezilula kunye nokusebenza kakuhle.

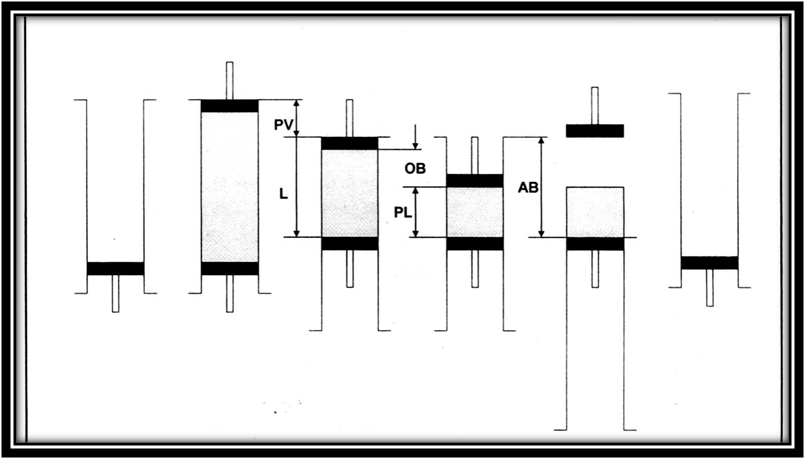

3. Ukucinezela isostatic ebandayo

Uxinzelelo lwe-isostatic olubandayo lusekelwe kumgaqo we-PASCAL; i powder ecinezelweyo ivalwe kwi-elastic mold enemilo ethile kunye nobukhulu, kwaye emva koko ifakwe kwisitya esivaliweyo soxinzelelo oluphezulu. Isiphakathi se-liquid siqhutyelwa kwisitya ngepompo yoxinzelelo oluphezulu, kwaye i-medium yenza uxinzelelo ngokulinganayo kumphezulu ngamnye we-elastic mold. I-powder kwi-mold elastic nayo iphantsi koxinzelelo olulinganayo kuwo onke amacala kwaye imilo yayo iyancitshiswa ngokulinganayo xa ifakwe, ukwenzela ukuba i-powder ihlanganiswe kwi-compact blank enemilo ethile, ubukhulu kunye namandla okwaneleyo.

Sintering

I-Sintering yinkqubo yokugqibela enkulu kwimveliso ye-carbide enesamente. Injongo ye-sintering kukutshintsha i-porous powder compact kwi-alloy enesakhiwo esithile kunye neempawu. I-Sintering ye-alloy enzima inzima ngakumbi ngenxa yotshintsho lomzimba kunye nokuphendula kweekhemikhali, kodwa ngenxa yenkqubo yomzimba, njengokuxinana komzimba we-sintering, ukukhula kweenkozo ze-carbide, utshintsho lwesigaba sokudibanisa kunye nokwakhiwa kwesakhiwo se-alloy.

Yonke inkqubo ye-sintering inokwahlulwa ngokwezigaba ezine:

Inqanaba lokutshisa kwangaphambili (

Inqanaba eliqinileyo lenqanaba le-sintering (800℃- ubushushu be-eutectic)

Ulwelo isigaba sintering isigaba (ubushushu eutectic - sintering ubushushu)

Inqanaba lokupholisa (iqondo lobushushu legumbi le-sintering)

Ukuba unomdla kwiimveliso ze-tungsten carbide kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, ungaQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL ezantsi kweli phepha.