Kutheni kwaye njani ukuWeld Carbide Grits kwiSanding Shaping Carving Wheel?

Kutheni kwaye njani ukuWeld Carbide Grits kwiSanding Shaping Carving Wheel?

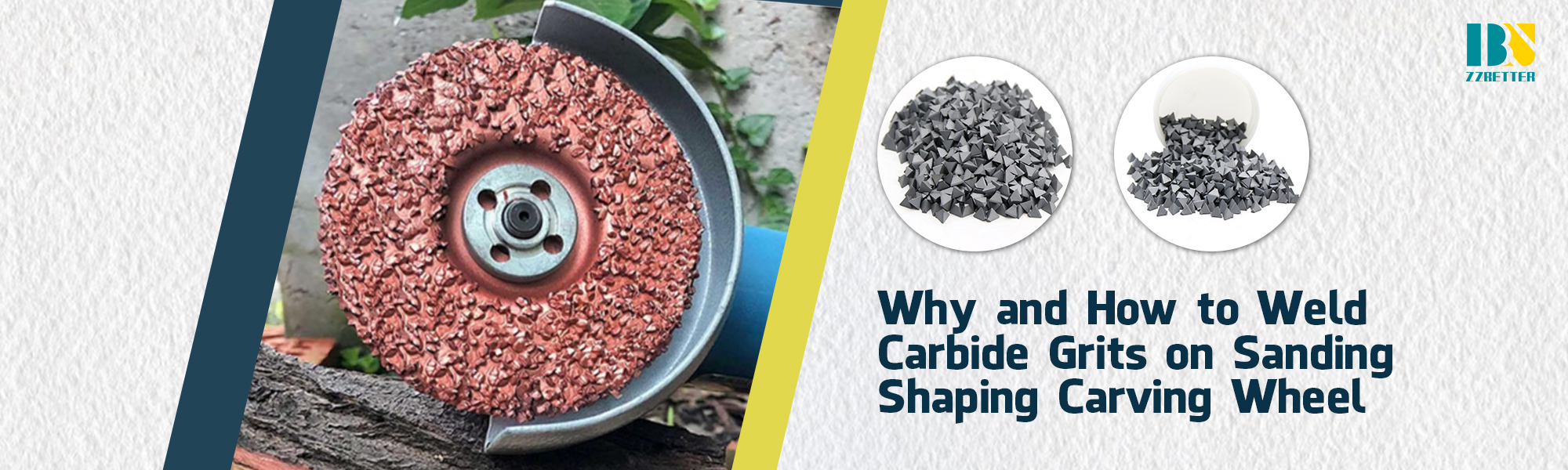

I-Welding carbide grits kwi-sanding, i-shaping, okanye ivili lokukrola ibonelela ngeenzuzo ezithile. I-Carbide yinto enzima kunye neyomeleleyo, eyenza ukuba ilungele ukusetyenziswa kwe-abrasive. Xa iigrits zecarbide zidityaniselwe kwivili, zenza indawo erhabaxa ekwaziyo ukusika, ukusila, okanye ukubumba izinto ezahlukeneyo, ezinjengomthi, isinyithi, okanye ilitye.

I-carbide grits edibeneyo ibonelela ngokuphucuka kokusebenza kokusika kunye nokuphila ixesha elide xa kuthelekiswa namavili abrasive amasiko. Ziyakwazi ukumelana namaqondo obushushu aphezulu kwaye azifane ziguge ngokukhawuleza. Oku kubenza basebenze ngakumbi kwimisebenzi efuna ukususwa kwezinto ezinzima okanye ukusetyenziswa ixesha elide.

Nanga amanyathelo aqhelekileyo okuwelda iigrits zecarbide kwivili:

1. Khetha ivili elilungileyo: Khetha ivili elilungele usetyenziso oluthile kunye nezinto oza kusebenza ngazo. Qwalasela izinto ezifana nobukhulu bevili, umlinganiselo wesantya, kunye nokuhambelana neegrits zecarbide.

2. Lungisa ivili: Coca umphezulu wevili ngocoselelo ukususa nabuphi na ubumdaka, inkunkuma, okanye iigrits ezindala. Eli nyathelo liqinisekisa ukunamathela kakuhle phakathi kwegrits carbide kunye nevili.

3. Faka imathiriyeli ye-welding: Ngokuxhomekeke kwindlela ethile yokuwelda esetyenziswayo, kunokufuneka ukuba ufake i-welding material okanye i-agent kumphezulu wevili. Esi sixhobo sisebenza njengento yokudibanisa i-carbide grits kwivili.

4. Beka iigrits ze-carbide: Beka ngononophelo iigrits ze-carbide kumphezulu wevili. Iigrits kufuneka zihlulwe ngokulinganayo kwaye zicwangciswe ngendlela efunwayo okanye uqwalaselo.

5. Unyango lobushushu: Faka ubushushu kwivili ukuze uvule imathiriyeli ye-welding kwaye uququzelele inkqubo yokudibanisa. Ubushushu obuthile kunye nobude bonyango lobushushu luya kuxhomekeka kwindlela ye-welding kunye nezixhobo ezisetyenzisiweyo.

6. Vumela ukuba kuphole kwaye uhlole: Nje ukuba inkqubo yokuwelda igqityiwe, vumela ivili liphole. Hlola ibhondi phakathi kwe-carbide grits kunye nevili ukuze uqinisekise ukuba yomelele kwaye ikhuselekile. Naziphi na iigrits ezikhululekileyo okanye ezingaqhotyoshelwanga kakuhle kufuneka zilungiswe okanye zitshintshwe.

Nceda uqaphele ukuba ubuchule be-welding obuchanekileyo kunye nezixhobo zinokuhluka ngokuxhomekeke kwisixhobo esithile kunye nokusetyenziswa. Kubalulekile ukuba ulandele iiprothokholi ezifanelekileyo zokhuseleko kunye nezikhokelo zomenzi ngexesha lenkqubo ye-welding ukuze kuqinisekiswe ibhondi eyimpumelelo nethembekileyo phakathi kwegrits ye-carbide kunye nevili.

Ukuba unomdla kwiCarbide Grits kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, UNGAQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ngasekhohlo, okanye SITHUMELE MAIL emazantsi ephepha.