- Intonga ye-tungsten ye-carbide eyenziwe nge-cemented carbide tips kunye ne-Ni / Ag (Cu) ialloy. Iingcebiso ze-carbide zihlala ziyi-tungsten carbide grits etyumkileyo, ukufaka i-carbide yokunxiba, njengokufakela imilo ye-carbide

- Ubunzima yi-89-91 HRA, i-binder metal yi-Ni kunye ne-alloy yobhedu, amandla angafikelela kwi-690MPa, ubunzima be-HB≥160.

Inkcazo

Sinomzi-mveliso okhethekileyo kwi-tungsten carbide, sibonelela nangezinye iimveliso ezininzi esingenako ukuzivelisa. uzibophelele kwiimveliso ezizezona ziluncedo kumntu ofuna ukufumana umgangatho olungileyo kunye neemveliso zamaxabiso angcono.

Inkcazo:

Intonga ye-tungsten ye-carbide eyenziwe nge-cemented carbide tips kunye ne-Ni / Ag (Cu) ialloy. Iingcebiso ze-carbide zihlala ziyi-tungsten carbide grits echotshoziweyo, i-carbide wear inserts, efana ne-carbide star shape inserts, i-carbide pyramid shape inserts, ukufaka imilo yokrebe njalo njalo. Ngamanye amaxesha, iingcebiso ze-carbide zinokuba yi-tungsten carbide powder. Ukhetho lwezoqoqosho yi-tungsten carbide grits etyumkileyo. Ukuba ufuna ukuhlala ixesha elide kune-carbide grits, ukufakwa kwe-carbide kungcono. Nangona kunjalo i-carbide enesamente / i-carbide etyumkileyo enomphetho obukhali inokumelana okugqwesileyo kunye nokukwazi ukusika.

Ubunzima yi-89-91 HRA, i-binder metal yi-Ni kunye ne-alloy yobhedu, amandla angafikelela kwi-690MPa, ubunzima be-HB≥160.

Ngokufutshane, uninzi lwentonga yeComposite eyenziwe kusetyenziswa iinkozo zeTungsten Carbide ezichotshoziweyo ezidityaniswe ne-nickel matrix yobhedu, (Cu 50 Zn 40 Ni 10) enendawo yokunyibilika ephantsi (870 ° C).

Ubungakanani beengqolowa zegrits ye-carbide:

1/8-1/16 ngaphakathi ( 3.2-1.6 mm)

3/16-1/8 kwi. (4.8-3.2 mm)

1/4-3/16 ngaphakathi (6.3-4.8 mm)

3/8-5/16 ngaphakathi (9.5-7.9 mm)

5/16-1/4 ngaphakathi (7.9 -6.3 mm)

3/8-1/4 ngaphakathi (9.5-6.3 mm)

1/2-5/16 ngaphakathi (12.7-7.9 mm)

Amabanga eentonga ezidibeneyo

Kukho amabakala amabini aphambili axhomekeke kwiCandelo elihlukeneyo legrits ye-tungsten carbide

IBanga

Iintlobo zeekhemikhali(%)

Ukusebenza ngokomzimba

Usetyenziso

WC

Cu+Zn+Sn

Co

BT-Cu-30

64-67

30±2

3.8-4.2

Ukuqina: >160 HB TRS: >690MPa

160 HB TRS: >690MPa

690MPa

Izixhobo zomngxuma ophantsi

Iiplanga

Iishafu

Izixhobo zezolimo/zemigodi

Vlaves

IiBleyi zeTurbineBT-Cu-40

53-56

40±2

4.6-4.8

BT-Cu-45

48-52

45±2

4.2-4.5

BT-Cu-50

44-48

50±2

3.8-4.2

Amalungu esixhobo

Imigqomo ye-Extruder kunye nezikrufuIntoCarbide gr

Appyayo

ubukhulu

ukuphelisa

Ububanzi obukhoyo (mm)

Ubude obukhoyo (mm)

1

1.6-3.2

1/8-1/16

(mm)

(intshi)

280- 450

2

3.2-4.8

3/16-1/8

3

4.8-6.4

1/4-3/16

4

6.4-8.0

5/16-1/4

5

8.0-9.5

3/8-5/16

6

9.5-11.0

7/16-3/8

7

11.0-12.7

1/2-7/16

I-Bare okanye ene-fluxed-coating

(20-22 ) (18-20 ) (10-12)Ubungakanani, ubunzima beyunithi, ubungakanani begrits bunokuba yi-OEM.

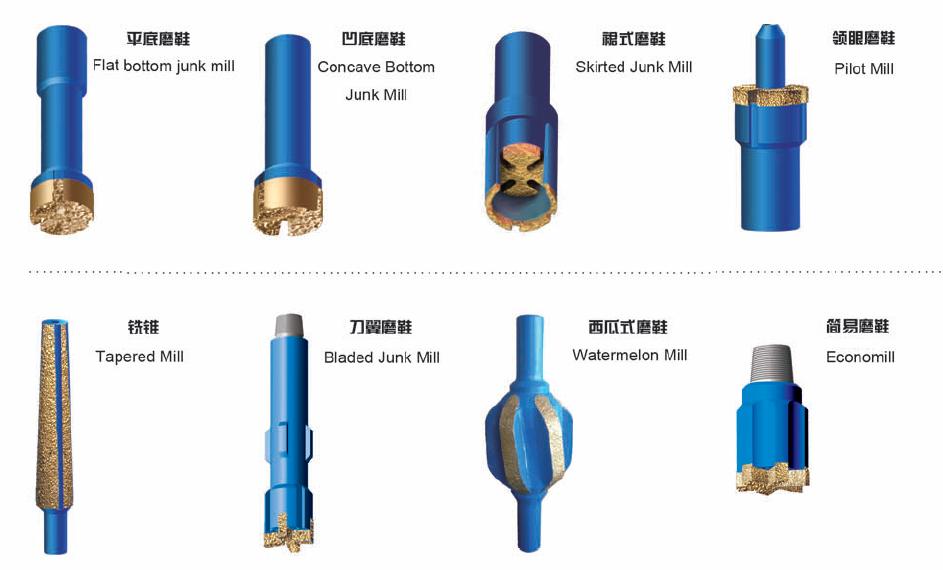

I-Composite rod welding iye yamkelwa kulo lonke uhlobo lwe-oyile yokomba, imigodi kunye neshishini lokwakha kwihlabathi jikelele ngokuqina kwayo okungaphezulu kunye neempawu zokungagugi kakhulu. Usetyenziso lunwenwela nakumashishini amaninzi kwaye kusetyenziswa kakhulu. I-welding yentonga ehlanganisiweyo ineempawu zokunxiba kunye nokusika ezidityaniswe kukuweldability okuphezulu kunye nokuvutha okuphantsi, okuvumela izinto ukuba zisebenzise.

kwizizinzisi, iireamers, udibaniso lwemibhobho yokomba, ukomba wolwakhiwo, ihydraulic-cutter, i-pipe cutter blades, core bit, scraper, twist drill, milling kunye nezihlangu zokusila njl.njl.

FAQ ye-Tungsten carbide composite rod

Umbuzo: Ngaba uyinkampani yokurhweba okanye umenzi?

A: Siyifektri.

Umbuzo: Lingakanani ixesha lokuhambisa kwakho?

A: Ngokubanzi kwiintsuku ze-7 ukuba iimpahla zikhoyo. okanye yi-15-20 iintsuku ukuba iimpahla azikho kwisitokhwe, kunjalo

ngokobungakanani.

Umbuzo: Ngaba uyabonelela ngeesampuli? isimahla okanye yongeziweyo ?

A: Ewe, sinokunikezela ngesampulu yentlawulo yasimahla kodwa ungahlawuli iindleko zothutho.

Q: Ithini imiqathango yakho yentlawulo?

A: Intlawulo

IZhuzhou Ingcono iTungsten Carbide Co., Ltd

Idilesi:B/V 12-305, Da Han Hui Pu Industrial Park, Zhuzhou City, China.

Ifowuni:+86 18173392980

Umnxeba:0086-731-28705418

Ifeksi:0086-731-28510897

imeyile:zzbt@zzbetter.com

Whatsapp/Wechat:+86 181 7339 2980