Izinzuzo, ukungalungi, kanye nomehluko phakathi kwensimbi enesivinini esikhulu ne-carbide enosimende

Izinzuzo, ukungalungi, kanye nomehluko phakathi kwensimbi enesivinini esikhulu ne-carbide enosimende

1. Insimbi enesivinini esikhulu:

Insimbi enesivinini esiphezulu iyinsimbi enekhabhoni ephezulu ne-alloy. Ngokusho kokwakheka kwamakhemikhali, ingahlukaniswa ngochungechunge lwe-tungsten nensimbi yochungechunge lwe-molybdenum, futhi ngokusho kokusika ukusebenza, ingahlukaniswa ngensimbi evamile enesivinini esiphezulu kanye nensimbi esebenza ngesivinini esiphezulu. Insimbi enesivinini esikhulu kufanele iqiniswe ngokuphathwa ukushisa. Esimeni sokucisha, i-iron, i-chromium, ingxenye ye-tungsten, nekhabhoni kufomu lensimbi yesivinini esikhulu i-carbides eqinile kakhulu, engathuthukisa ukumelana nokugqokwa kwensimbi (ukuqina bungafinyelela ku-HRC64-68).

Enye ingxenye ye-tungsten incibilika ku-matrix futhi inyusa ubulukhuni obubomvu bensimbi. Ubulukhuni obubomvu bensimbi enesivinini esiphezulu bungafinyelela kuma-degree angu-650. Insimbi enesivinini esikhulu inamandla amahle kanye nokuqina. Ngemuva kokucija, umkhawulo wokusika ubukhali futhi ikhwalithi izinzile. Ngokuvamile isetshenziselwa ukwenza amathuluzi amancane, amise okuyinkimbinkimbi.

2. I-carbide enosimende:

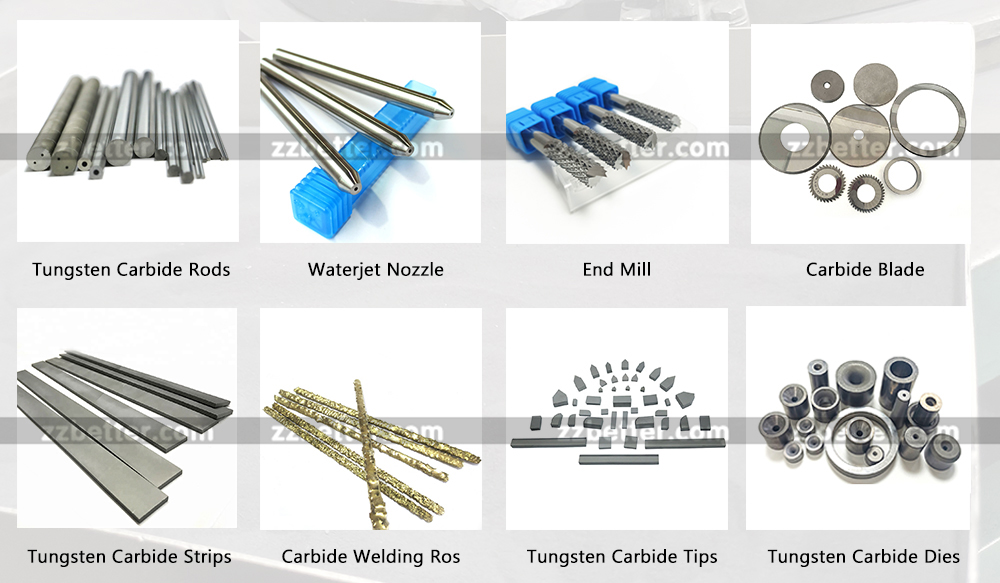

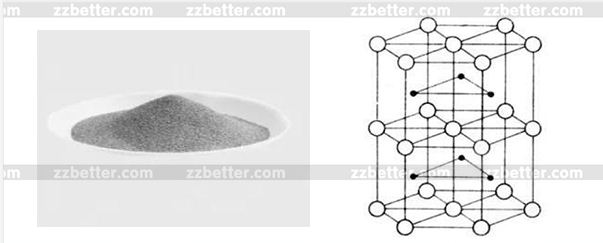

I-Cemented carbide iyi-micron-order refractory high-hardness metal carbide powder, eyenziwa ngokudubula ngezinga lokushisa eliphezulu kanye nokucindezela okukhulu nge-cobalt, i-molybdenum, i-nickel, njll. njenge-binder. Okuqukethwe kwama-carbide okushisa aphezulu ku-carbide enosimende kudlula okwensimbi enesivinini esikhulu, enobunzima obuphezulu (HRC75-94) nokumelana nokugqokwa okuhle.

Ubulukhuni obubomvu be-alloy bungafinyelela ku-800-1000 degrees. Ijubane lokusika le-carbide enosimende liphakeme izikhathi ezi-4-7 kunelensimbi enesivinini esikhulu. High ukusika ukusebenza kahle.

I-carbide enosimende inokuqina okuphezulu, amandla, ukumelana nokuguga, nokungagqwali, futhi yaziwa ngokuthi "amazinyo ezimboni". Isetshenziselwa ukwenza amathuluzi okusika, imimese, amathuluzi e-cobalt, nezingxenye ezingagugi, futhi isetshenziswa kabanzi kwezempi, i-aerospace kanye nezindiza, ukucutshungulwa komshini, i-metallurgy, ukumba uwoyela, amathuluzi ezimayini, ezokuxhumana nge-elekthronikhi, ezokwakha neminye imikhakha, ngokuthuthukiswa kwezimboni ezansi nomfula, isidingo semakethe ye-carbide enosimende siyaqhubeka nokukhula. Futhi esikhathini esizayo, ukukhiqizwa kwezikhali nemishini yobuchwepheshe obuphezulu, ukuthuthuka kwesayensi nobuchwepheshe obusezingeni eliphezulu, kanye nokuthuthukiswa ngokushesha kwamandla enuzi kuzokwandisa kakhulu isidingo semikhiqizo ye-carbide enobuchwepheshe obuphezulu, kanye nezinzile. .