Isingeniso Se-Hardfacing kanye Nezinto Zaso Ze-Carbide

Isingeniso Se-Hardfacing kanye Nezinto Zaso Ze-Carbide

Eminyakeni edlule i-hardfacing ibe yinkinga yentuthuko ejulile ehlobene nezicelo ezingezwani nokugqoka. I-Hardfacing, eyaziwa nangokuthi “I-Hardsurfacing”, ukusetshenziswa kwezinsimbi zokushisela ezakhayo noma ezingagugi endaweni yengxenye ngendlela yokushisela noma yokuhlanganisa ukuze imelane nokuhuzuka, ukugqwala, izinga lokushisa eliphezulu, noma umthelela. Ukubekwa kwezingubo eziwugqinsi zezinto eziqinile, ezingagugi endaweni egugile noma entsha engase iguge enkonzweni. Ukufafaza okushisayo, i-spray-fuse kanye nezinqubo zokushisela ngokuvamile zisetshenziselwa ukufaka ungqimba oluqinile. Ingxubevange enjalo ingase ifakwe phezulu, onqenqemeni, noma nje iphuzu lengxenye engase igqokwe. Amadiphozi wokushisela angenza izindawo ezingaphezulu zisebenze futhi afune kabusha izingxenye ezinweba impilo yazo yesevisi. Ukushisela ubuchwepheshe obubalulekile bokufeza lezi zidingo kanye nokusebenzisa ama-alloys aqinile. Izingxenye ezibalulekile ezifana nama-crushers zichayeka ekugugileni okukhulu futhi zidinga izinyathelo zokuvikela indawo ezisebenza kahle ukuze zigweme izikhathi zokwehla ezibizayo kanye nokunciphisa izindleko zezingxenye eziyisipele ezibizayo. Le nqubo yamukelwe ezimbonini eziningi ezifana Nosimende, Imayini, Insimbi, I-Petro-chemical, Amandla, umoba kanye Nokudla.

I-Tungsten carbide ingenye yezinto ezinzima kakhulu ezitholakalayo ukuze zisetshenziswe ezimbonini. Angeke incibilikiswe yinoma yiliphi ilangabi elivamile lezinga lokushisa eliphansi. Ibuye ibe brittle. Ngezinhloso eziqinile, ichotshozwa futhi isetshenziswe ngokuhambisana nensimbi "ebophayo". Izinhlayiya ze-tungsten carbide zivame ukuvalwa endongeni yeshubhu yensimbi.

I-ZZBETTER inezinto zokushisela ze-hardfacing ezinjengalezi:

1.I-Tungsten Carbide Wear Insets:

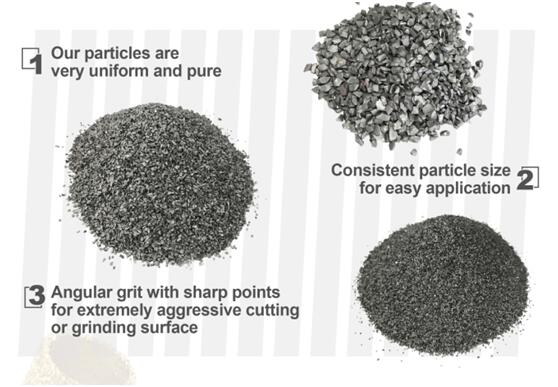

2.I-Tungsten Carbide Grits:I-Tungsten carbide grit ihlinzeka ngokuvikelwa kokugqokwa okuhlala isikhathi eside ezindaweni zokugqokwa okuphezulu kwe-abrasive. Isetshenziselwa ukuvikela izingxenye ezibizayo njengama-bulldozer blades, amazinyo ebhakede, ukugaya izinkuni, izando, amazinyo e-trencher, kanye nezinhlobonhlobo zezinye izinto ezisetshenziswayo. I-Tungsten Carbide grit iyindlela ephumelelayo yokuvikela izingxenye zemishini nemishini ngokunikeza ukwanda okuphawulekayo kobude bokuphila kwalezo zingxenye. Lokhu kunciphisa isikhathi sokuphumula futhi kunciphisa izindleko ezithintekayo nezingxenye ezingavikelekile.

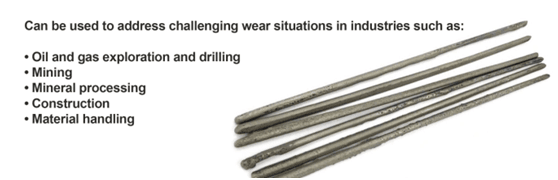

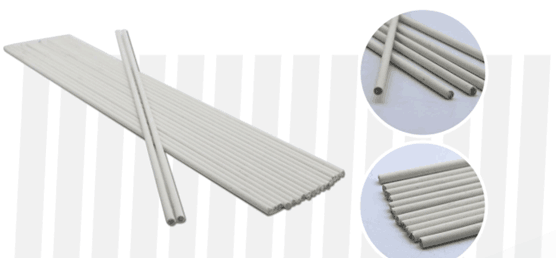

3.Izinduku Ezihlanganisiwe ezine-Carbide Insert: Lezi zinduku eziyinhlanganisela ezisebenza kahle zisebenzisa izinti zethu ze-carbide ezikunikeza imiphetho ebukhali enolaka kanye nokuqina okudingekayo ezindaweni ezibalulekile zethuluzi lakho lokugaya.

4.I-Nickel Carbide Composite Rods: Izinti eziyinhlanganisela ye-nickel carbide beziwukuqina kanye nokulungiswa kwezingcezu zokusika ezingaguquki futhi zisetshenziswa njengesivikelo sokugqokwa kwezinzinzisi nama-reamers embonini kawoyela negesi. Ama-pellets amakhulu e-tungsten carbide ahlinzeka ukumelana nokuhuzuka kuyilapho ama-pellets amahle avikela i-matrix ekugugeni nasekugugulekeni. I-nickel matrix inikeza ukumelana nokugqwala okusezingeni eliphezulu, ivikela umzimba omncane futhi ivumele ukulungiswa komsiki kanye nokuphinda kusetshenziswe ikhanda lokubhoboza.

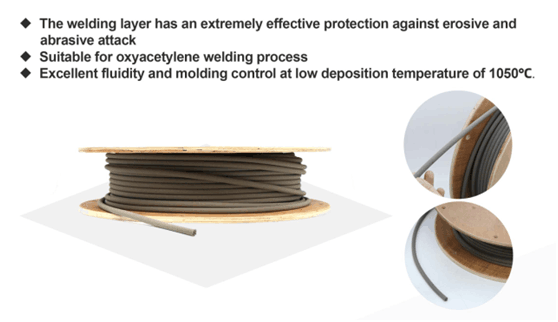

5.Intambo Yokushisela Eguquguqukayo: Intambo yokushisela eguquguqukayo yenziwe nge-cast tungsten carbide, i-spherical cast tungsten carbide noma ingxube yakho kokubili njengesigaba esiqinile, i-self-fluxing nickel alloy powder yesigaba sokubopha, ngokuya ngengxenye ethile yokuhlanganisa okuxubile, ukubumba kwe-extrusion, ukomisa, bese kukhiqizwa ngocingo lwe-nickel.

6.I-Nickel Silver Tinning Rods: Izinti ze-nickel silver tinning ziyizinduku ze-oxyacetylene zenhloso evamile zokushisela izinsimbi ezihlukahlukene ezinensimbi nezingezona ayoni, njengensimbi, i-cast iron, ironableable, namanye ama-alloys e-nickel. Avame ukusetshenziselwa ukushisela okuhlanganisiwe kwethusi, ithusi, nama-alloys ethusi kanye nokwakha izindawo ezigugile.

7.Faka i-Tungsten Carbide powder: I-Cast tungsten carbide powder, evame ukubizwa ngokuthi i-W2C, iyinto eqinile kakhulu esetshenziselwa izinhlelo zokusebenza ezihlukahlukene. Ngesakhiwo se-eutectic, indawo ephezulu yokuncibilika nobulukhuni, obungasiza ekuvikelweni kokugqoka kanye nezakhiwo zokumelana nokugqoka. Impahla ikhiqizwaisuka engxubeni ye-carbon, tungsten ne-tungsten carbide powder futhi iyisiliva/mpunga ngombala nokuma kwezinhlayiyana ezicijile.

8.I-Tungsten Carbide Pellet Welding Rods: Uma kuqhathaniswa ne-cast tungsten carbide powder, amapellets e-tungsten carbide anomthelela ongcono nokumelana nokugqoka. Inezici ze-welding yesikhathi esisodwa ngaphandle kwe-reflow soldering. Ama-pellets ayindilinga; i-coefficient ye-friction incane, enganciphisa ukuguga kwe-casing futhi ingabizi.

Umbuzo: Ingabe i-hardfacing iwufanele?

I-Hardfacing ingenziwa ngokusebenzisa izinqubo ezihlukahlukene, kokubili esitolo nasensimini, okwenza kube nezinto ezihlukahlukene kakhulu futhi kungabizi kakhulu. Ukwengeza, ukusebenzisa le nqubo ezingxenyeni ezintsha kunganweba impilo yesevisi ngama-300%. Noma kunjalo, uma izingxenye ezigqokwe eziqinile, ungonga kufika ku-75% uma kuqhathaniswa nezindleko zokushintshwa.

Ukuphetha, i-hardfacing iyinqubo eguquguqukayo kakhulu yokuthuthukisa impilo yengxenye egugile; i-hardfacing iyindlela engcono kakhulu ekhethiwe kulezi zinsuku yokunciphisa izindleko zokushintshwa; i-hardfacing inciphisa isikhathi sokuphumula ngoba izingxenye zihlala isikhathi eside futhi ukuvalwa okumbalwa kuyadingeka ukuze kuthathelwe indawo; hardfacing kungenziwa kunoma iyiphi impahla steel usebenzisa anhlobonhlobo izinqubo Welding.

Uma uthanda imikhiqizo ye-tungsten carbide futhi ufuna ulwazi olwengeziwe kanye nemininingwane, UNGAXHUMANA NATHI ngocingo noma nge-imeyili kwesokunxele, noma SITHUMELE IMEYILI ezansi kwaleli khasi.