Izifundo ze-HPGR Nokugcinwa

Izifundo ze-HPGR Nokugcinwa

Okokuqala nje. yini i-HPGR? I-HPGR iphinde ibizwe nge-High-Pressure Grinding Roll. Kunegebe elincane phakathi kwamarola okugaya amabili ukunciphisa izinhlayiya ngokucindezela nokuchoboza okuphakelayo. Ekugayeni, izikhonkwane ze-tungsten carbide zisebenza kahle.

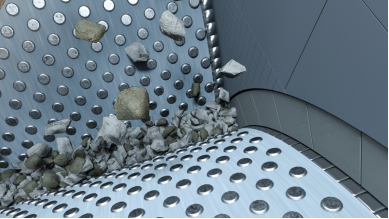

Izikhonkwane ze-HPGR zenziwe nge-tungsten carbide njengengxenye eyinhloko yerola yokugaya enengcindezi ephezulu, eqinile futhi ekwazi ukumelana nokucindezela okuphezulu nomthelela ophezulu. Ngenxa yalezi zinzuzo, asetshenziswa kakhulu ezimayini, isihlabathi namatshe, usimende, i-metallurgy, ubunjiniyela bamandla kagesi, nezinye izimboni.

Njengamanje, ukugcinwa kwe-HPGR roller surface yesigayo se-high pressure roller kusekelwe ikakhulukazi ekushintsheni okwenziwa ngesandla kwe-roller stud. Okokuqala, i-roller stud ephukile isuswa ngesikhathi, futhi i-roller stud entsha ifakwe endaweni yokuqala ye-roller nail ngesikhathi. Izinga lokuguga le-roller surface ye-high pressure roller mill lihlobene kakhulu nobunzima be-ore, ubukhulu be-ore bulukhuni, ukuguga kwe-roller kubi nakakhulu. Ukwengeza, isigayo se-high pressure roller ngokuvamile sifakwe umgqomo ohambisanayo, okwenza ikholomu yezinto ezibonakalayo phakathi kwama-roller amabili, angagwema ngokuphumelelayo ukungqubuzana kwesibili okubangelwa ukuhlala kwezinto endaweni ye-roller ye-high pressure roller mill.

Ngabhala isihloko mayelana nokwethulwa kwe-HPGR carbide studs ngaphambili, futhi ngezansi kwesihloko, othile wabuza:Ungashintsha kanjani izigxobo namabhulokhi wedivayisi ye-HPGR?Nansi impendulo engiyaziyo manje.

Indlela yokushintsha i-Stud:

Lapho i-stud yonakalisiwe, i-stud ingashiswa ibe ngu-180-200 ℃, ukuze okunamathelayo kulahlekelwe yi-viscosity, ngoba i-stud kanye ne-roller surface ye-stud hole iyi-gap fit, kulula ukuyikhipha i-stud eyonakele, futhi esikhundleni. nge-stud entsha, umkhono we-roller ungaqhubeka nokusebenzisa.

Indlela yokulungisa ubuso be-HPGR:

Okokuqala khetha indawo yomshini wokugaywa onengcindezi ephezulu enemigodi okufanele ilungiswe, hlanza imigodi, bese ushisela ungqimba oluwugqinsi luka-3mm ngaphansi kwemigodi, lungisa isigxobo se-carbide esinosimende ngomkhono wensimbi engagqwali, bese uvala ungqimba lwe ungqimba lwe-welding olungagugi kungqimba lwe-welding yokuxhuma phakathi komkhono wensimbi engagqwali ngamunye, uchungechunge lwedizayini yenqubo yokuqinisekisa ukuthi i-carbide stud enosimende kanye nenhlanganisela ye-roller surface iqine kakhulu ngempilo ende yesevisi, ukuze umkhono we-roller uguge kakhudlwana- ukumelana, kulula ukusebenza, ukonga izindleko, futhi kunezinzuzo zokusebenza okulula, ukuklama okunengqondo nokukhanda kalula.