Ungayikhetha Kanjani Ikhwalithi ephezulu ye-Tungsten Carbide Rotary Burr

Ungayikhetha Kanjani Ikhwalithi ephezulu ye-Tungsten Carbide Rotary Burr

Ama-tungsten carbide rotary burrs asetshenziswe kabanzi ekwakhiweni kwemikhumbi, ekuthuthweni kwenjini ye-auto, nasekwakhiweni kwesisekelo. Ngejubane layo eliphezulu elijikelezayo nobulukhuni, i-tungsten carbide rotary burr ingakwazi umshini izinto ezihlukene, njengensimbi ekhonjiwe, insimbi ye-carbon, insimbi ye-alloy, kanye nezinto ezingezona insimbi. Isevisi yempilo ephezulu yomkhiqizo iqinisekisa impahla eluhlaza enhle kakhulu, okungenye yezinto ezibaluleke kakhulu empilweni ye-carbide burr. I-Carbide rotary burrs ingasetshenziswa kuwo womabili amathuluzi aphethwe ngesandla anamandla kagesi nasebenza emoyeni ukuze asike izinto ezihlanganisa i-aluminium, ithusi, ama-titanium alloys, insimbi yokusansimbi, nethusi. Zingasetshenziswa kakhulu ku-pneumatic, amathuluzi okushayela kagesi. Ngakho-ke indlela yokukhetha i-tungsten carbide rotary burr yekhwalithi ephezulu ibaluleke kakhulu kubaqhubi nabasebenzi bokuthenga. Nazi izindlela ezimbalwa zokukhetha i-tungsten carbide rotary burr yekhwalithi ephezulu.

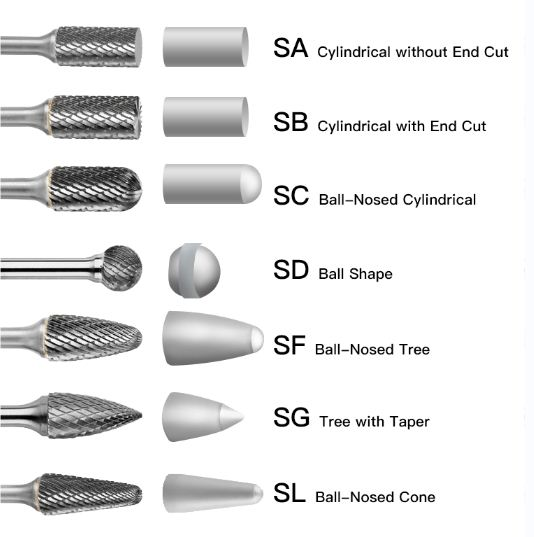

1. Khetha umumo we-tungsten carbide rotary burrs

Ukuma kwesigaba se-cemented carbide rotary burr cutter kufanele kukhethwe ngokuma kwe-workpiece okufanele icutshungulwe ukuze izimo zezingxenye ezimbili zihambisane. I-semi-circular burr noma i-burr eyindilinga (ucezu lokusebenza oluwububanzi obuncane) kufanele kukhethwe ukucubungula indawo ye-arc yangaphakathi, ama-triangular burrs ukuze kucutshungulwe indawo yangaphakathi yekhona, kanye ne-burr eyisicaba noma i-square burr yendawo engaphakathi kwesokudla. Uma i-burr eyisicaba isetshenziselwa ukusika indawo engaphakathi ye-engeli yesokudla, kuyadingeka ukwenza indawo encane (unqenqema olubushelelezi) ngaphandle kwamazinyo eduze kweyodwa ye-engeli engaphakathi kwesokudla ukuze ugweme ukulimaza i-engeli elungile.

2. Khetha ubukhulu bezinyo be-carbide rotary burr

Ubukhulu bamazinyo e-burr kufanele bukhethwe ngokuya ngosayizi wemvume ye-workpiece, ukunemba komshini, kanye nezakhiwo zezinto ezibonakalayo. I-coarse-tooth carbide burr ifanele izingcezu zokusebenza ezinemvume enkulu, ukunemba kwe-dimensional ephansi, isimo esikhulu nokubekezelela isikhundla, inani elikhulu lokuma okungaphezulu, nezinto ezithambile; ngaphandle kwalokho, kufanele kukhethwe i-fine-tooth carbide burr. Uma isetshenziswa, kufanele ikhethwe ngokuya ngemvume yomshini, ukunemba kwe-dimensional, kanye nobukhulu obungaphezulu obudingwa isiqeshana sokusebenza.

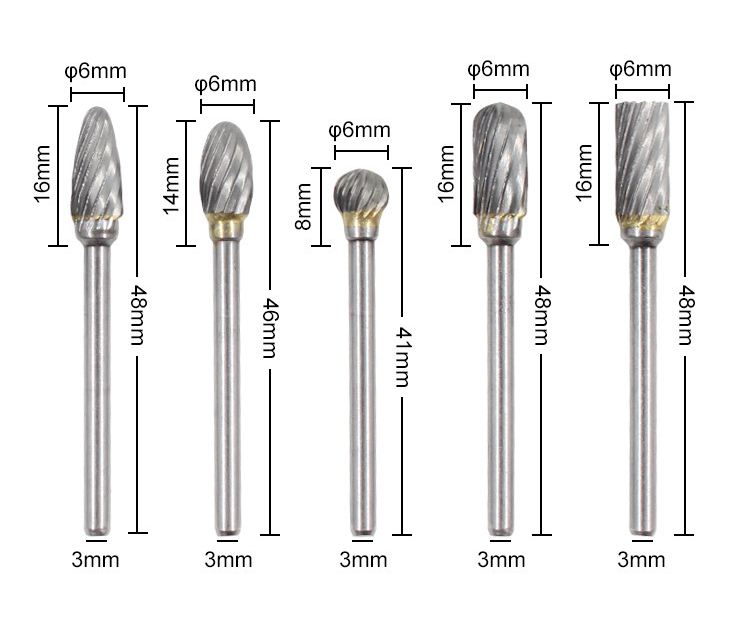

3. Khetha usayizi kanye nokucaciswa kwe-carbide burr

Usayizi nokucaciswa kwe-cemented carbide rotary burr kufanele kukhethwe ngokuya ngosayizi wesiqeshana sokusebenza kanye nemvume yomshini. Uma usayizi womshini futhi imvume inkulu, kufanele kukhethwe i-carbide rotary burr enosayizi omkhulu, noma kufanele kukhethwe i-tungsten carbide rotary burr enosayizi omncane.