Indlela yokushisela i-Snow Plow nge-Tungsten Carbide

Indlela yokushisela i-Snow Plow nge-Tungsten Carbide

Amagama angukhiye: amazinyo okulima iqhwa; i-tungsten carbide; ifosholo igeja iqhwa; i-carbide enosimende

Lesi sihloko sichaza ngokuyinhloko inqubo yamazinyo efosholo okulima iqhwa kanye ne-tungsten carbide welding. Okokuqala, i-square groove yokufaka imigoqo ye-carbide enosimende yenziwa ngomshini phezulu kwe-embryo yamazinyo efosholo, futhi umfutho we-hydraulic osizayo wenziwa ngokufaka amathuluzi wokushisela we-hydraulic ngefosholo ukuze i-square groove phezulu kwamazinyo efosholo i-embryo yakhelwe ngamanzi. i arc. Indawo engaphansi ye-arc groove iphansi phakathi futhi iphakeme nhlangothi zombili. Bese, i-brazing filler metal encibilikisa umucu we-carbide kasimende kanye nezinto ezingenalutho zezinyo lefosholo ezishiselwa emzimbeni ukuze zakhe amazinyo efosholo, ngomshini wokushisela ophakathi kwamafrikhwensi wokushisela.

amazinyo efosholo okulima iqhwa asetshenziswa kakhulu ngaphambili kwefosholo elingagqoki leqhwa lezinto zefosholo, ezidinga ukumelana nokugqoka okuphezulu kanye nokucaba. Amazinyo efosholo akhona kakade enziwe ngensimbi ye-carbon steel, i-alloy steel noma i-die steel, enokumelana nokugqokwa okubi kanye nomthelela omkhulu empilweni yesevisi. I-Carbide inobunzima obuphakeme kakhulu, futhi ukumelana okungcono kakhulu kokugqoka kwempahla, okwakhiwe i-hardness carbide kanye ne-alloy, inokumelana nokugqoka okuphezulu, kodwa ukuqina akulungile, futhi inqubo yokushisela kulula ukuqhekeka. Ngokusebenzisa inani elikhulu lokuhlola, sithole ukuthi ukusebenzisa inqubo evamile yokushisela kuzodala ukuwohloka kwepuleti lensimbi, ukuqhekeka kwe-alloy, nezinye izinkinga.

Izinyathelo zokusebenza:

1. Sika ipuleti lensimbi elivamile lekhabhoni libe sesimweni sezinto ezingenalutho zamazinyo efosholo leqhwa.

2. Phezulu kwezinyo leqhwa elingenalutho, i-groove yesikwele yokufaka imicu ye-carbide enosimende yenziwa ngomshini.

3. Yenza ithuluzi lokushisela lefosholo le-hydraulic, faka umbungu wegiya lefosholo ethuluzini lokushisela le-hydraulic lefosholo ukuze uthole umfutho we-hydraulic ukuze i-square groove phezulu kwegiya lefosholo i-embryo ibe yi-hydraulic arc groove, indawo engaphansi ye-arc. i-groove iphansi phakathi nendawo futhi iphakeme kuzo zombili izinhlangothi ze-arc surface.

4. Faka insimbi yokugcwalisa phansi kwe-arc groove phezulu kwezinyo leqhwa elingenalutho, bese ufaka umugqa we-carbide kasimende emseleni we-arc, ukuze insimbi yokugcwalisa ibe phakathi komugqa we-carbide osikiwe naphansi. we-arc groove.

5. Umshini wokugqamisa i-medium frequency induction brazing usetshenziselwa ukushisela, futhi umugqa we-carbide kasimende uxhunywe nefosholo lefosholo leqhwa izinyo elingenalutho ngokuncibilikisa insimbi yokubhula ukwenza izinyo lefosholo leqhwa.

6. Ngemva kokushisela, pholisa amazinyo efosholo ashiselwe ekamelweni lokushisa.

Isiphetho:

Ukuxazulula izinkinga zokuqhekeka kwe-deformation kanye ne-alloy phakathi kwamazinyo efosholo kanye nomugqa we-carbide osikiwe ngemuva kokushisela, okusunguliwe kusebenzisa ubuchwepheshe bokushisela be-arc hydraulic. Okokuqala, i-groove yesikwele yokufaka imichilo ye-carbide enosimende yenziwa ngomshini phezulu kwento engenalutho yamazinyo efosholo, futhi umfutho we-hydraulic osizayo wenziwa yithuluzi lokushisela i-hydraulic lamazinyo efosholo. I-square groove phezulu kwezinyo lezinyo lephosholo leqhwa lakhiwe ngogesi libe yi-arc groove.

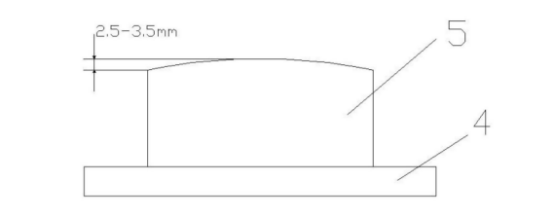

Indawo engezansi ye-arc groove iyi-arc enezinhlangothi eziphansi eziphakathi nendawo eziphakeme. Umehluko phakathi kwephuzu eliphansi phakathi nendawo ye-arc kanye nephuzu eliphakeme kunazo zonke ezinhlangothini zombili ngu-2.5 kuya ku-3.5mm. Bese kuthi ngomshini ophakathi nendawo ongenisa i-frequency brazing wokushisela, ngokusebenzisa i-brazing filler metal encibilika umucu we-carbide usimende kanye nezinto ezingenalutho zezinyo lefosholo ezishiselwe emzimbeni ukuze zakhe amazinyo efosholo.

Ngokusebenzisa inqubo yokushisela i-arc hydraulic welding, inani le-deformation le-arc groove lingalawuleka ngokunembile, ukuze i-hydraulic pretension kanye nokucindezeleka kwangaphakathi kwe-snow plovel slovel tooth embryo kanye nomugqa we-carbide osikiwe kukwazi ukuhlukana, futhi okuphambene. inani le-deformation kanye nenani le-welding deformation lingakwazi ukuqedana, ngaleyo ndlela kunciphise kakhulu amathuba okuguqulwa kwezinyo lefosholo leqhwa kanye nethuba lokuqhekeka kwe-welding ye-carbide enosimende. Ngesikhathi esifanayo, iphinde ithuthukise kakhulu ukucaba, ukumelana nokugqoka, kanye nempilo yesevisi yamazinyo efosholo.

Ibha ye-carbide enosimende eshiselwe ekupheleni kwamazinyo efosholo iyingxubevange eyenziwe ngensimbi ephikisayo nensimbi eboshwe ngenqubo ye-powder metallurgy, enobunzima obuphezulu, ukumelana nokugqoka, amandla nokuqina, ukumelana nokushisa, ukumelana nokugqwala kanye nochungechunge lwe izakhiwo ezinhle kakhulu, ikakhulukazi ubulukhuni bayo obuphezulu nokumelana nokugqoka, ngisho naku-500 ℃ izinga lokushisa alishintshile.

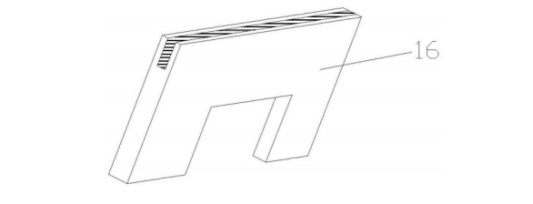

Umfanekiso 1

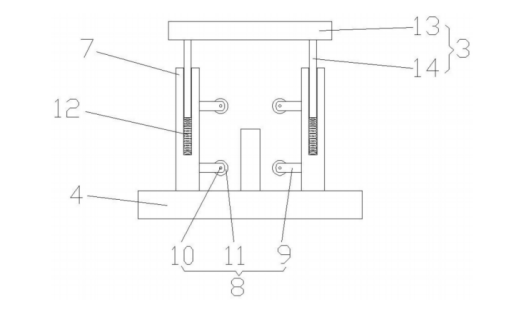

Umfanekiso 2

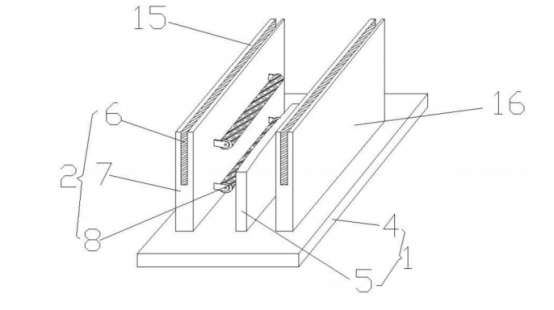

Umfanekiso 3

Umfanekiso 4

Okunye okuqukethwe kwalesi sihloko kucaphuna futhi kuhumusha okuvela embikweni waseShayina welungelo lobunikazi Lokusungula. Sethemba ukuthi lolu lwazi luwusizo kuwe, futhi wamukelekile ukushiya imibono nemibuzo yakho ngezansi. I-ZZBETTER inikeza imikhiqizo ehlukahlukene ye-tungsten carbide ngamanani afanele. Silindele uphenyo lwakho uma udinga noma yini ehlobene ne-carbide enosimende, vele usinike imidwebo yakho, singakwazi ukwenza okulungile kuwe.