Indlela yokuthuthukisa impilo yesevisi yomdwebo wezintambo uyafa

Indlela yokuthuthukisa impilo yesevisi yomdwebo wocingo uyafa?

1. Zama ukukhetha ukucubungula okufanele futhi ukhiqize umdwebo we-carbide wire dies.

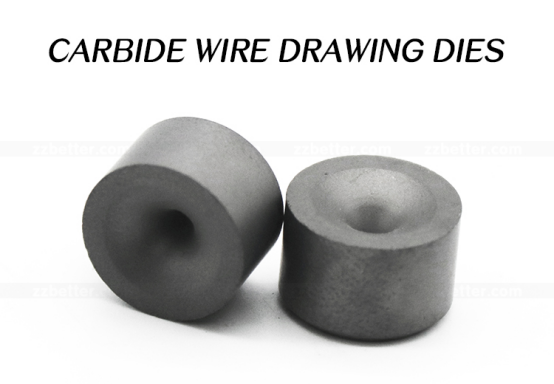

Umdwebo wocingo uyafa okhiqizwe yi-ZZBETTER uyacindezelwa futhi wakhiwe ngokucindezela ongeniswe kwamanye amazwe futhi ufakwe esithandweni somlilo esicindezela kakhulu. Futhi sebenzisa isibonakhulu esikhethekile ukuze uhlole ukufa komdwebo wocingo ukuze uhlole ukuphela kwendawo.

2. Khetha i-wire drawing die ekhiqizwa ezintweni ezingavuthiwe

Njengamanje, abakhiqizi abaningi basebenzisa izinto ezigaywe kabusha zokukhiqiza ukuze bonge izindleko. Umdwebo uyafa okhiqizwe ezintweni ezigaywe kabusha ushibhile, kodwa kunezinkinga ngokumelana nokugqoka kanye nempilo yesevisi. Wonke amabhizinisi kufanele abheke ngokucophelela lapho ukuthenga umdwebo kufa. Umdwebo wocingo uyafa okhiqizwe yi-ZZBETTER sebenzisa i-tungsten powder eluhlaza ngokuhlanzeka okungaphezu kuka-99.95% njengento eluhlaza eyinhloko, enokungcola okuphansi futhi akukho ukuthosa. Kusetshenziswa ubuchwepheshe befomula obukhethekile kanye nokwengeza izinto ezingagugi, impilo yesevisi yomdwebo wezintambo ithuthukiswa kakhulu.

3. Ukufakwa nokusetshenziswa komshini wokudweba ngocingo kufanele kube okunengqondo

(1) Isisekelo sokufakwa komshini wokudweba ucingo sidinga ukuzinza kakhulu ukugwema ukudlidliza;

(2) Ngesikhathi sokufakwa, i-axis eqinile yocingo kufanele ilingane nomugqa omaphakathi wembobo yokufa ngokususa iphutha ukuze ukucindezelwa kocingo kanye nomdwebo wocingo kufane.

(3) Gwema ukuqala nokumisa njalo phakathi nenqubo yokudweba ucingo ngoba ukungqubuzana okubangelwa ukucindezeleka okuqinile ekuqaleni komdwebo kukhulu kakhulu kunokungqubuzana phakathi nokudweba okuvamile, okuzokwandisa nakanjani ukuguga kwesikhunta.

4. Ucingo olusetshenziselwa ukudweba kufanele lufakwe ngaphambili

(1) Ukwelashwa kwangaphambili komhlaba: ngocingo olunendawo engcolile nokungcola okuningi, kufanele luhlanzwe futhi lomiswe ngaphambi kokudweba; ocingweni olunesikali se-oxide ngaphezulu, kufanele lufakwe emanzini anosawoti futhi lomiswe kuqala. Bese uyikhipha; ezintanjeni ezixebukayo, ezigobhozayo, esikhumbeni esinzima, nezinye izenzakalo ezingaphezulu, kufanele zigaywe ngomshini wokupholisha ngaphambi kokudonsa;

(2) Ukwelashwa kokushisa: Ocingweni olunobulukhuni obudlulele noma ubulukhuni obungalingani, ubulukhuni kufanele buncishiswe ngokufaka i-anneal noma ukushisa kuqala, futhi ucingo kufanele lugcine ubulukhuni obuhle ngaphambi kokudweba.

5. Gcina izinga elifanelekile lokunciphisa indawo yokudweba

Umdwebo we-carbide wire die ngokwawo unezici zokuqina nokuqina. Uma isetshenziselwa umdwebo wokunciphisa ububanzi ngezinga elikhulu lokunciphisa indawo, kulula ukubangela ukufa ukuthi imelane nokucindezeleka futhi kuphuke futhi kukhishwe. Ngakho-ke, kuyadingeka ukukhetha ucingo olufanele ngokusho kwezakhiwo zemishini yocingo. Isilinganiso sokunciphisa indawo siyathathwa. Intambo yensimbi engagqwali idwetshwa nge-carbide die enosimende, futhi izinga lokushwabana kwendawo yokudlula eyodwa ngokuvamile alibi ngaphezu kwama-20%.

6. Sebenzisa izinto zokugcoba ezinezakhiwo ezinhle zokugcoba

Phakathi nenqubo yokudweba, ikhwalithi kanye nokunikezwa okwanele kwe-lubricant kuzothinta impilo yesevisi yokufa komdwebo wocingo. Ngakho-ke, kuyadingeka ukuthi isisekelo sikawoyela wokuthambisa sizinze, sibe nokumelana okuhle kwe-oxidation, ukuthambisa okuhle kakhulu, ukupholisa, nokuhlanza izindawo, futhi ngaso sonke isikhathi sigcine isimo esihle sokugcoba kuyo yonke inqubo yokukhiqiza ukuze kwakhiwe ungqimba olungamelana nokucindezela okuphezulu ukonakala. Ifilimu inganciphisa ukungqubuzana endaweni yokusebenza futhi ithuthukise impilo yesevisi yesikhunta. Phakathi nenqubo yokusetshenziswa, isimo samafutha okugcoba kufanele sigcinwe ngokuqhubekayo. Uma amafutha okugcoba anombala noma impushana yensimbi, kufanele ashintshwe noma ahlungwe, okungagwema i-oxidation kanye nokuwa okuncane phakathi nenqubo yokudweba. Izinhlayiya zensimbi zilimaza isikhunta.

7. Ukugcinwa njalo nokulungiswa komdwebo kuyafa

Ngesikhathi sokusetshenziswa kwesikhathi eside komdwebo wocingokufa, udonga olufayo lungaphansi kokungqubuzana okuqinile nokuguguleka kwentambo yensimbi, okuzobangela ukuguga nakanjani. I-ring groove ye-wire-donsa die yenza kube nzima ukuguga kwembobo yokufa ngenxa yokuthi i-core material iyaxebuka. I-ring groove evulekile ilethwa endaweni yokusebenza kanye nendawo yokulinganisa yembobo yokufa ngocingo lwensimbi, olusebenza njenge-abrasive futhi lungene emgodini wokufa. Ucingo lufana nezinaliti zokugaya, okwenza kube nzima ukuguga kwembobo yokufa. Uma ingashintshwa futhi ilungiswe ngesikhathi, i-groove ring izoqhubeka nokukhula ngesivinini esisheshayo, okwenza ukulungisa kube nzima nakakhulu, futhi kungase kube nokuqhekeka engxenyeni ejulile ye-groove ring, okubangela ukuba isikhunta siphuke ngokuphelele futhi. elahliwe.

Kusukela kokuhlangenwe nakho, kubiza kakhulu ukwenza isethi yamazinga, ukuqinisa ukunakekelwa kwansuku zonke, nokulungisa isikhunta njalo. Uma isikhunta sesinokugqoka okuncane, ukupholisha okufika ngesikhathi kuzothatha isikhathi esincane ukubuyisela isikhunta esimweni saso sokupholishwa, futhi usayizi wembobo yokubumba ngeke ushintshe kakhulu.

Uma unentshisekelo emikhiqizweni ye-tungsten carbide futhi ufuna ulwazi olwengeziwe nemininingwane, UNGATHI XHUMANA NATHI ngocingo noma nge-imeyili kwesokunxele, noma SITHUMELE IMEYILI ezansi nekhasi.