Isingeniso Of Hardbanding

Isingeniso Of Hardbanding

![]()

I-Hardbanding iwukunamathela kwensimbi ukumelana nokuguga I-Hardbanding iyinqubo yokubeka phezu kwento enamathelayo noma phezu kwensimbi eqinile] engxenyeni yensimbi ethambile. Kusetshenziswa i-gas metal arc welding endaweni yangaphandle yamajoyinti ethuluzi lepayipi lokubhoboza ukuze kukhuliswe amalunga ethuluzi lepayipi lokubhoboza, amakholola, nempilo yesevisi yamapayipi okubhola anesisindo esisindayo kanye nokunciphisa ukuguga kwentambo ye-casing kusukela ekugugeni okuhambisana nezinqubo zokumba.

I-Hardbanding isetshenziswa lapho ukungqubuzana okujikelezayo kanye ne-axial okuhlotshaniswa nokubhola nokukhubeka kudala ukuguga okweqile phakathi kwentambo yokubhoboza ne-casing noma phakathi kwentambo yokubhoboza nedwala. Imbondela ye-Hard alloy isetshenziswa kumaphuzu okuthintana kakhulu. Ngokuvamile, i-hardbanding isetshenziswa ekuhlanganyeleni kwethuluzi njengoba kuyingxenye ebanzi kakhulu yentambo yokubhoboza futhi izothintana ne-casing kaningi.

Ekuqaleni, izinhlayiya ze-tungsten-carbide zaphonswa ku-matrix yensimbi ethambile, ehlala indinganiso yemboni iminyaka eminingi. Kodwa-ke, abanikazi bemithombo basheshe baqaphela ukuthi nakuba ithuluzi elihlangene lalivikeleke kahle, izinhlayiya ze-tungsten-carbide zazivame ukusebenza njengethuluzi lokusika ngokumelene ne-casing, okubangela izinga elibi kakhulu lokuguga kanye nokwehluleka okuphelele kwekesi ngezikhathi ezithile. Ukuze kubhekwane nesidingo esibalulekile somkhiqizo we-hardbanding ovumela i-casing-friendly ongavikela ngokwanele amalunga amathuluzi namanye amathuluzi omgodi.

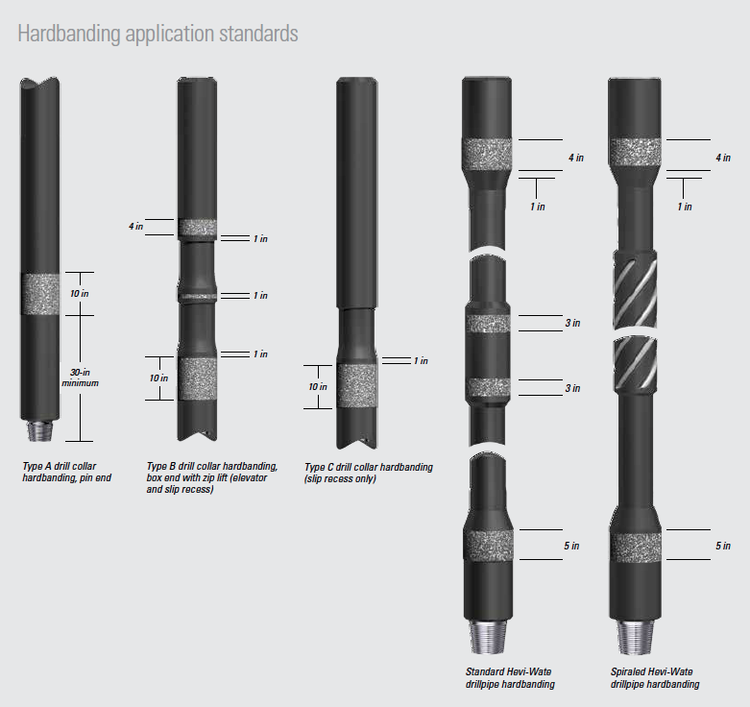

Izinhlobo ze-hardbanding:

1. I-hardbanding ephakanyisiwe (IYAQHOSHA)

2. I-Flush hardbanding (FLUSH)

3. I-Hardbanding ekuphazamisekeni okumaphakathi kwe-Drill Collar kanye ne-Heavy Weight Drill Pipe

Imisebenzi ye-Hardbanding:

1. Ivikela ithuluzi lepayipi lokubhoboza ekuhutsheni nasekugugekeni futhi inwebe impilo yesevisi ye-DP.

2. Ivikela amalunga ethuluzi ekuqhekekeni okushisayo.

3. Yehlisa ukuguga kwe-casing.

4. Yehlisa ukulahleka kokungqubuzana kokumba.

5. I-Hardbanding ivumela ukusetshenziswa kwamajoyinti amathuluzi ashiselwe i-OD emincane.

Izicelo ze-Hardbanding:

1. I-Hardbanding iyasebenza ekubhoboleni amapayipi abo bonke osayizi namabanga.

2. I-Hardbanding ingase isetshenziswe ku-u sed tubular entsha.

3. I-Hardbanding ingasetshenziswa ekuhlanganiseni kwethuluzi lamapayipi okubhoboza okwenziwe nge-GOST R 54383-2011 ngayinye kanye ne-GOST R 50278-92 noma ngemininingwane yobuchwepheshe yezigayo zamapayipi kazwelonke, nasemajoyintini ethuluzi lamapayipi okubhola enziwe ngokwe-API Spec 5DP.

4. Ibhande eliqinile lingase lisetshenziswe kumapayipi okubhoboza anezinhlobo ezahlukene zamajoyinti amathuluzi, okuhlanganisa amathuluzi anamahlombe amabili.

5. Ibhande eliqinile lingase lisetshenziswe kumapayipi okubhoboza angakwazi ukumelana nokubanda kanye ne-DP yesevisi emuncu.

I-Hardbanding ingasetshenziswa kuma-tubular wezinhlobo ezilandelayo namasayizi:

1. Umzimba wepayipi OD 60 kuya ku-168 mm, ubude bufika ku-12 m, i-OD yamajoyinti amathuluzi ashiselwe ngokwemibhalo ye-DP ngayinye.

2. I-Hardbanding isetshenziswa ekuphazamisekeni kwe-HWDP, ezindaweni ezihlangene zamathuluzi e-HWDP, kanye ne-DC yazo zonke izinhlobo nosayizi.

3. I-Hardbanding iphinde isetshenziswe ekuphazamisekeni okuphakathi kwe-HWDP ne-DC.

4. Ibhande eliqinile lingasetshenziswa emajoyini amathuluzi ngaphambi kokuba ashiselwe epayipini lokubhoboza.

Ukonga okukhiqizwa ngokusebenzisa ipayipi lokubhoboza eline-hardbanding:

1. Impilo yesevisi yepayipi lokubhoboza inwetshwa izikhathi ezi-3.

2. Ukugqoka ngokuhlanganyela kwamathuluzi kuncipha ngo-6-15 % kuye ngohlobo lwe-hardbanding esetshenzisiwe.

3. Ukuguga kwezindonga ze-casing kwehliswe ngo-14–20 % uma kuqhathaniswa nokuguga okubangelwa amalunga amathuluzi angenalutho.

4. Yehlisa ukulahleka kokungqubuzana kwemithombo.

5. I-torque ye-rotary edingekayo iyancipha, ngaleyo ndlela inciphisa ukusetshenziswa kwamandla.

6. Ithuthukisa ukusebenza kokumba.

7. Yehlisa isikhathi sokumba.

8. Yehlisa imvamisa yentambo yokubhoboza nokuhluleka kwentambo ye-casing emisebenzini yokumba.