Ukwethulwa komdwebo we-Tungsten Carbide Wire Dies

Ukwethulwa komdwebo we-Tungsten Carbide Wire Dies

Umdwebo we-carbide wire uyafa usebenzisa i-tungsten carbide yekhwalithi ephezulu njengomongo, onobulukhuni obuphezulu, ukuguquguquka okuhle kwe-thermal, kanye ne-coefficient ephansi yokungqubuzana. Umdwebo wocingo lwe-Tungsten carbide uyafa kulula ukuwukhiqiza ngendlela evikela ukugqwala, ukumelana nokuthinteka, kanye nezindleko eziphansi, ezinesici esivelele salo mkhiqizo. Ifanele izinsimbi ezisansimbi, izintambo ezinosayizi omkhulu, kanye nezikhathi ezinezimo ezingezinhle zokudweba ngocingo.

Ukudweba ngocingo kuyinqubo yokukhiqiza yokunciphisa noma yokushintsha ingxenye enqamulayo yocingo lwensimbi ngokusebenzisa uchungechunge lwamapuleti aluliwe noma isikhunta. I-Carbide wire drawing die iwuhlobo lwe-tungsten carbide efayo ngokusetshenziswa okubanzi emikhakheni ehlukahlukene.

I-YG6X: Ifanele ukukhiqizwa kwe-carbide iyafa ngokudweba izimbobo zangaphakathi ezincane kuno-Φ6.00mm.

I-YG6: Isetshenziselwa ibha eyindilinga yensimbi engeyona insimbi, enezimbobo ezidwetshiwe ezingaphakathi ezincane kuno-Φ20mm, futhi umdwebo uyafa, onezimbobo ezingaphakathi ezincane kuno-Φ 10mm.

YG8, YG10: Applied for drawing steel and the production of non-ferrous metal round bars & pipes.

I-YG15: Isetshenziselwa izinti zensimbi namapayipi anokuncipha okuphezulu.

I-Tungsten carbide wire drawing dies inezici ezilandelayo eziqinisekisa ukuqina okuphezulu:

1. Ukumelana namandla okuqinile

2. Ukumelana nokugqoka okuhle kakhulu

3. Ukuqina okwanele kokushisa

4. Ikhono elihle kakhulu lenqubo

Izindaba ezidinga ukunakwa nokunakekelwa komdwebo we-carbide wire ziyafa:

1. Qinisekisa ukuzinza komshini wokudweba

Ngesigubhu sokudweba ngasinye, iziqondiso ze-over-line kufanele zibe bushelelezi, ziguquguquke, futhi zilawulwe ngokuqinile ukuze zikwazi ukushaya ukubekezelelana. Uma isigubhu sitholakala, isondo lomhlahlandlela linomsele ogugile, futhi umdwebo uyafa kufanele ulungiswe ngesikhathi.

2. Ukugcoba okuhle

Ukugcoba okuhle kubalulekile ukuze kuqinisekiswe izinga eliphezulu locingo futhi kwandise impilo yesevisi yesikhunta. Inkomba yokugcoba kufanele ihlolwe njalo, isuse impushana yethusi, nokungcola ku-lubricant, ukuze imbobo yemishini ingangcoliswa. Uma i-lubrication ingasebenzi, kufanele ishintshwe ngesikhathi futhi ihlanzwe.

3. I-allotype enengqondo

I-allotype enengqondo iwukuqinisekisa ikhwalithi engaphezulu yentambo nokulawula ukunemba kosayizi, ukwehlisa ukuguga kwesigubhu sokudweba izintambo nomthwalo wokusebenza kwempahla. Ngemishini yokudweba ngocingo olushelelayo, kuyadingeka ukuthi uzijwayeze nokwelulwa kwemishini kwemishini. I-coefficient eshelelayo ikhethwe ngokufanele, okuyisinyathelo esiyinhloko sokufaka isikhunta.

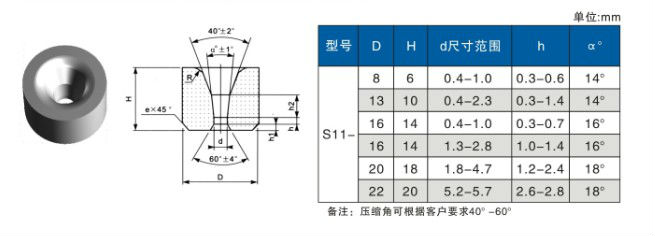

4. Ukulungiswa okufanele kosayizi we-engeli yokucindezela

Izinga lokunciphisa indawo yomdwebo ngamunye kanye nezinto zocingo oludwetshiwe nazo zihlotshaniswa eduze ne-engeli yokucindezela yesikhunta esifanele. Usayizi we-engeli yokucindezela ulungiswa ngokufanelekile ngokuya ngosayizi wezinga lokunciphisa indawo.

5. Ukushintshwa okufika ngesikhathi komdwebo wokuguga kuyafa

Uma umdwebo ufinyelela impilo yesevisi, sicela uyishintshe kusenesikhathi ukuze ulungise ukwelashwa ukuze ugweme ukudaleka ngokweqile kocingo.

I-tungsten carbide wire drawing dies isetshenziswa kabanzi ukudweba ezimbonini ezahlukahlukene. Inokuqina okuphezulu, ukuzinza okuhle kakhulu kokushisa, ukuqina okuphezulu, nempilo ende yesevisi futhi ingenye yezinto ezihamba phambili zokubumba.

Uma unentshisekelo emikhiqizweni ye-tungsten carbide futhi ufuna ulwazi olwengeziwe nemininingwane, UNGATHI XHUMANA NATHI ngocingo noma nge-imeyili kwesokunxele, noma SITHUMELE IMEYILI ezansi nekhasi.