Inqubo Yokukhiqiza kanye Nenqubo Yokwenza I-Cemented Carbide Rod

Inqubo Yokukhiqiza kanye Nenqubo Yokwenza I-Cemented carbide rod

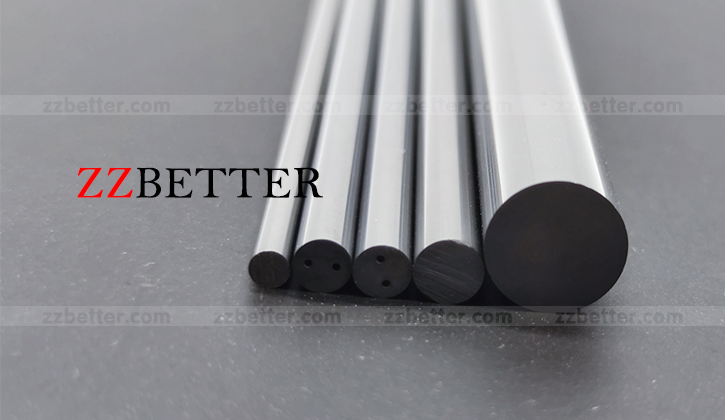

Imigoqo ye-carbide enosimende iyizinti eziyindilinga ze-carbide zikasimende. I-carbide enosimende iyinhlanganisela eyenziwe ngenhlanganisela yensimbi ephikisayo (isigaba esiqinile) kanye nensimbi yokubopha (isigaba sokubopha) ekhiqizwa yimpushana yensimbi.

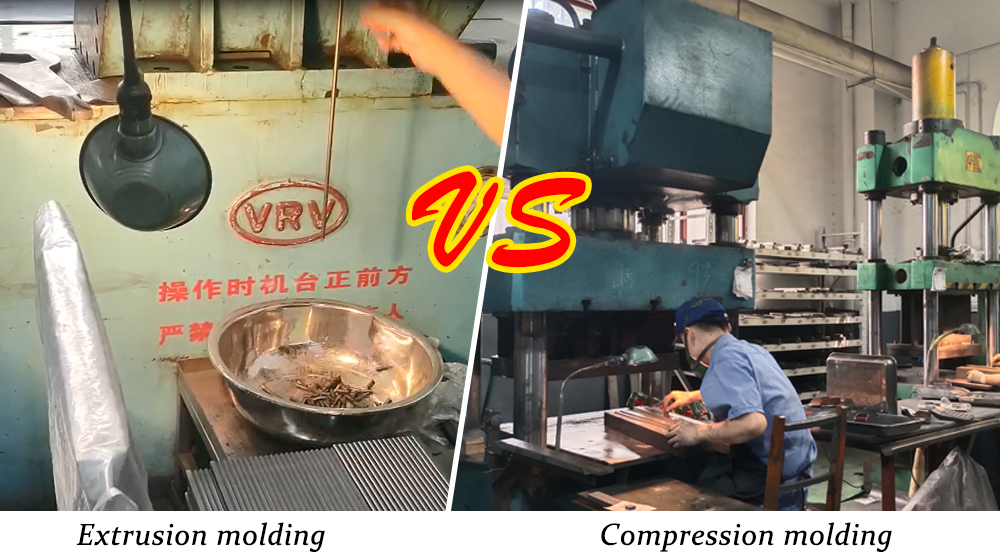

Kunezindlela ezimbili zokwakha izinti eziyindilinga ze-carbide zikasimende. Enye indlela ukwakhiwa kwe-extrusion, okuyindlela efanelekile yokukhiqiza izinduku ezinde eziyindilinga. Lolu hlobo lwezinduku ze-carbide ezinosimende zingasikwa zibe yinoma yibuphi ubude obufunwa ngumsebenzisi ngesikhathi senqubo yokukhipha. Nokho, ubude bubonke abunakudlula u-350mm. Enye i-compression molding, okuyindlela efanelekile yokukhiqiza ibha emifushane. Njengoba igama lisho, i-carbide powder enosimende icindezelwa ibe yisikhunta.

I-alloy material yenziwe ngensimbi ephikisayo kanye nensimbi ebophayo ngokusebenzisa inqubo ye-powder metallurgy. I-carbide enosimende inochungechunge lwezakhiwo ezinhle kakhulu njengokuqina okuphezulu, ukumelana nokugqoka, amandla amahle nokuqina, ukumelana nokushisa, nokumelana nokugqwala. ikakhulukazi ubulukhuni bayo obuphezulu nokumelana nokugqoka, okuhlala kungashintshile ngisho nasezingeni lokushisa elingu-500 °C, futhi kusenokuqina okuphezulu ku-1000 °C. I-Carbide isetshenziswa kabanzi njengezinto zamathuluzi, njengamathuluzi okuguqula, abasiki bokugaya, amapulani, izinsimbi, amathuluzi ayisicefe, njll. futhi ingasetshenziselwa ukusika Ukugaywa okumanzi kwezinto okunzima ukuzilungisa njengensimbi engashisi, insimbi engagqwali, insimbi yemanganese ephezulu, insimbi yamathuluzi (isigayo sebhola, ikhabethe elomisayo, i-Z-type mixer, igranulator)---ukucindezela (ngokucindezela kwe-hydraulic hydraulic eseceleni noma i-extruder)-- - I-Sintering (isithando somlilo esishisayo, isithando somlilo esihlanganisiwe noma isithando somlilo esinomfutho ophansi we-HIP)

Izinto ezisetshenziswayo zigaywa ngamanzi, zomisiwe, zixutshwe neglue ngemva kokulinganisa, bese zomiswa futhi zinciphise ukucindezeleka ngemva kokubunjwa noma ukukhushulwa, futhi i-alloy yokugcina engenalutho yenziwa ngokukhipha amafutha kanye ne-sintering.

Ububi bokukhiqizwa kwe-round bar extrusion ukuthi umjikelezo wokukhiqiza mude. Ukunwetshwa kwemigoqo eyindilinga enobubanzi obuncane ngaphansi kuka-3mm, ukusika iziphetho zombili kuzomosha inani elithile lempahla. Uma ubude bebha eyindilinga enobubanzi obuncane be-carbide enosimende, buba bubi nakakhulu ukuqondisa kokungenalutho. Yiqiniso, izinkinga zokuqondisa nokujikeleza zingathuthukiswa ngokugaya i-cylindrical esigabeni sakamuva.

Enye i-compression molding, esetshenziselwa ukukhiqiza imigoqo emifushane. Njengoba igama lisho, kunesikhunta esicindezela i-carbide powder enosimende. Inzuzo yale ndlela yokwenza ibha ye-carbide enosimende: ingakhiwa ngesikhathi esisodwa futhi inciphise imfucuza. Lula inqubo yokusika ucingo futhi ulondoloze umjikelezo wezinto ezomile wendlela ye-extrusion. Isikhathi esifushane esingenhla singonga izinsuku ezingu-7-10 kumakhasimende.

Ukukhuluma ngokuqinile, ukucindezela kwe-isostatic nakho kungokokubumba. Ukucindezela kwe-Isostatic kuyindlela enhle kakhulu yokwakha yokukhiqiza amabha ayindilinga amakhulu namade e-carbide. Ngokuvala amapiston angaphezulu naphansi, iphampu yokucindezela ijova uketshezi oluphakathi kwesilinda esinengcindezi ephezulu kanye nerabha ecindezelweyo, futhi ukucindezela kudluliselwa ngerabha ecindezelwe ukwenza i-carbide powder press-molded.

Uma unentshisekelo emikhiqizweni ye-tungsten carbide futhi ufuna ulwazi olwengeziwe nemininingwane, UNGATHI XHUMANA NATHI ngocingo noma nge-imeyili kwesokunxele, noma SITHUMELE IMEYILI ezansi nekhasi.