Ukulawulwa kwekhwalithi yabasiki be-PDC

Ukulawulwa kwekhwalithi yabasiki be-PDC

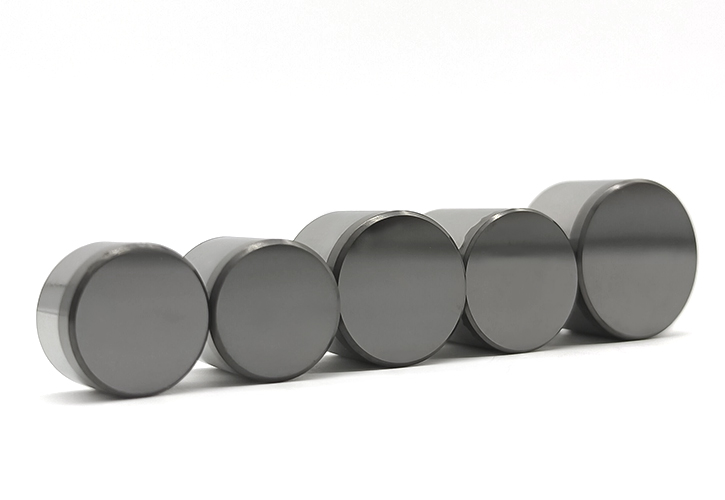

Abasiki be-PDC bahlanganisa isendlalelo se-Polycrystalline Diamond kanye ne-carbide substrate. Abasiki be-PDC baphinde baqanjwe ngokuthi abasiki be-Polycrystalline Diamond Compact , okuwuhlobo lwempahla eqinile kakhulu. Ukusetshenziswa kwezisiki ze-polycrystalline diamond compact (PDC) kusabalale kabanzi namuhla ngenxa yokusebenza kwazo okuphezulu nokuqina ezindaweni ezinokhahlo.

Izinto ezibaluleke kakhulu zabasiki be-PDC ekusetshenzisweni kokumba endaweni kawoyela kuyikhwalithi nokuvumelana. Ngikholwa ukuthi wonke umuntu uzovuma. Kodwa kanjani ukulawula izinga?

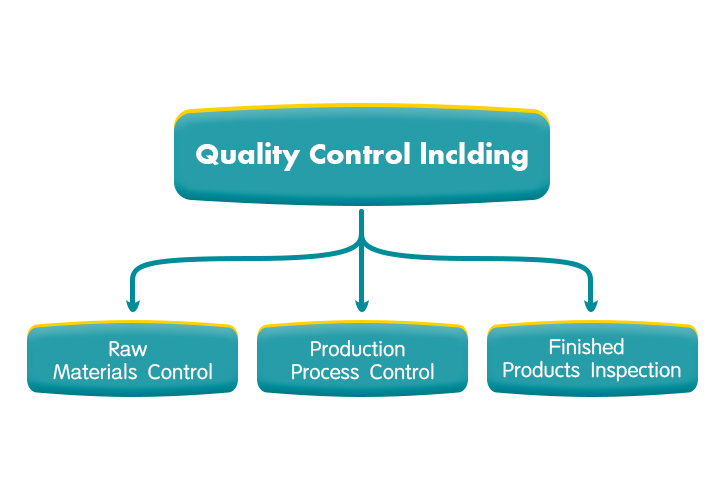

Ukuqinisekisa ukuthi yonke isiqephu se-PDC cutter siyafika ZZNGCONOizandla zekhasimende ezinekhwalithi ephezulu, ZZNGCONOisungule uhlelo oluqinile lokulawula ikhwalithi, okuhlanganisa ukulawula impahla eluhlaza, ukulawulwa kwenqubo yokukhiqiza, nokulawula imikhiqizo eqediwe. Umsebenzi wethu uqeqeshwe kakhulu futhi uchwepheshe kakhulu futhi uzinikele. Umsiki ngamunye we-PDC wakhiwe ngama-opharetha aqeqeshwe kakhulu futhi ingcindezi ilawulwa emishinini yokunyathelisa ngesikhathi se-sintering.

Ukulawulwa kwekhwalithi ye-PDC cutter:

1. Impahla eluhlaza

2. Inqubo yokukhiqiza

3. Ukuhlolwa kwemikhiqizo eqediwe

1. Ukulawula impahla eluhlaza

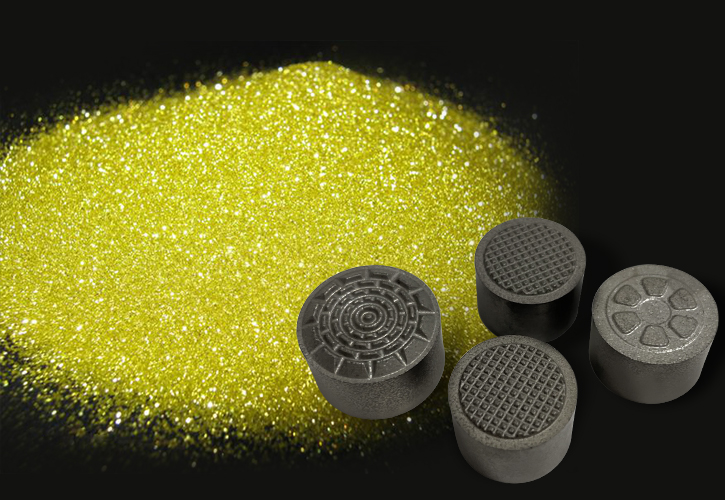

1.1 Ukwenza isicelo sokumba i-PDC cutter oilfield sisebenzisa idayimane elingenisiwe. Kudingeka futhi siyichoboze futhi siyilolonge futhi, senze usayizi wezinhlayiyana ufane. Kudingeka futhi sihlanze impahla yedayimane.

1.2 Sisebenzisa I-Laser Particle Size Analyzer ukuze sihlaziye ukusabalalisa usayizi wezinhlayiyana, ubumsulwa kanye nosayizi weqoqo ngalinye lempushana yedayimane.

1.3 Nge-tungsten carbide substrate sisebenzisa ibanga elilungile elinokumelana nomthelela omkhulu.

2. Inqubo yokukhiqiza

2.1 Sino-opharetha ochwepheshe kanye nezinsiza ezithuthukile zokukhiqiza abasiki be-PDC

2.2 Ngesikhathi sokukhiqiza sizohlola izinga lokushisa nengcindezi ngesikhathi sangempela futhi silungise ngesikhathi. Izinga lokushisa ngu-1300 - 1500℃. Ingcindezi ingu-6 - 7 GPA. I-HTP iyacindezela.

Ukukhiqiza ucezu olulodwa lwe-PDC Cutters uzodinga cishe imizuzu engama-30 isiyonke.

Kuwo wonke ama-batch we-PDC cutters, ucezu lokuqala lubaluleke kakhulu. Ngaphambi kokukhiqiza ngobuningi, sizohlola ucezu lokuqala ukuze sibone ukuthi luyahlangabezana yini nezidingo zekhasimende zobukhulu nokusebenza.

3.Ukuhlolwa kwemikhiqizo eqediwe

Ukuqinisekisa ukuthi bonke abasiki be-PDC bafanelekile futhi abaguquguquki, akufanele silawule kuphela ukuhlolwa kwezinto ezingavuthiwe kanye nokulawulwa kokugeleza kokukhiqiza kanye nokuthuthukiswa kwamasu, kufanele futhi sizibophezele ekwakheni ilabhorethri enezindawo zokuhlola ezithuthukisiwe ukulingisa izimo zokumba inkundla kawoyela nokuhlola abasiki be-PDC efektri. ngaphambi kokudiliva kumakhasimende ethu.

Ukulawula umkhiqizo oqediwe sizokwenza kusuka ezicini ezingezansi:

Ukuhlolwa kosayizi nokubukeka

Ukulawula ukukhubazeka kwangaphakathi

Ukuhlolwa kokusebenza

3.1 Ukuhlolwa kosayizi nokubukeka:ububanzi, ukuphakama, ukujiya kwedayimane, i-chamfer, osayizi bejometri, ukuqhekeka, indawo emnyama, njll.

3.2 Ukulawula ukukhubazeka kwangaphakathi

Ukulawula ukukhubazeka kwangaphakathi sizosebenzisa imishini yokuhlola esezingeni eliphezulu engenisiwe ye-C-san. Ukuze uthole abasiki be-PDC abafakwe uwoyela kufanele siskene zonke izingcezu.

Ngesistimu yokuskena i-C, igagasi le-ultrasonic lingangena ungqimba lwe-PDC futhi lithole ukubola kwalo noma ukungasebenzi kahle komgodi. Isistimu yokuskena i-C ingathola usayizi nendawo yeziphambeko futhi ikubonise esikrinini se-PC. Kuzothatha cishe imizuzu engu-20 ukuhlola isikhathi esisodwa.

3.3 Ukuhlolwa kokusebenza kwesampula kokusebenza kwe-PDC Cutter:

ukumelana nokugqoka

ukumelana nomthelela

ukuzinza okushisayo.

3.3.1 I-Wear Resistance Test:ngokukala ukuthi zingaki izisindo ezilahlekile ngemva kokuba abasiki be-PDC begawula igwadle ngesikhathi esithile, sithola isilinganiso sokuguga. Ukulahlekelwa okukhulu phakathi kwabasiki be-PDC kanye ne-granite. Lapho isibalo siphezulu, ama-PDC Cutters azoba namandla ngokwengeziwe.

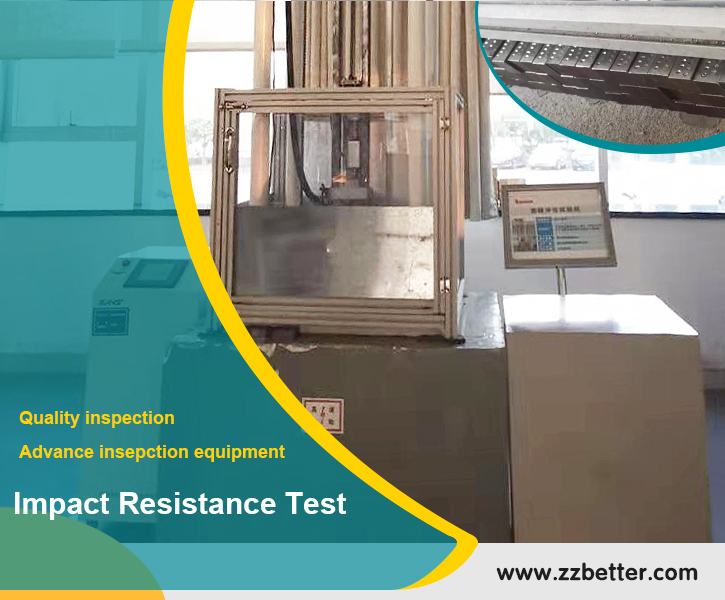

3.3.2UmthelelaUkuhlolwa kokumelana:Siphinde sikubize ngokuthi i-Drop-Weight test, sisebenzisa i-lathe eqondile ekuphakameni okuthile igxilisa iphrofayili yokusika ye-PDC Cutter, ngokuvamile enezinga elithile (15-25 degree) slide. Izisindo zale lathe eqondile kanye nobude bayo obusethiwe kungabonisa ukuthi lesi sisiki se-PDC singamelana kanjani nomthelela.

3.3.3 Ukuhlolwa Kokuqina Kokushisa:Kuhloswe ngayo ukuhlola ukuthi ama-PDC Cutters azinzile yini ngokushisa ngokwanele ngaphansi kwezimo zokushisa eziphezulu zokusebenza. Elabhorethri, sibeka abasiki be-PDC ngaphansi kuka-700-750℃emizuzwini eyi-10-15 bese uhlola isimo sesendlalelo sedayimane ngemva kokupholisa kwemvelo emoyeni. Ngokuvamile le nqubo izohambisana nokunye ukumelana nokugqoka kanye nokumelana nomthelela ukuze kuqhathaniswe ikhwalithi yomsiki we-PDC ngaphambi kokuhlolwa nangemuva kokuhlolwa.

Siyakwamukela ukulandela ikhasi lenkampani yethu:https://lnkd.in/gQ5Du_pr

Funda kabanzi:WWW.ZZBETTER.COM