Indlela Ohlukumeza Ngayo End Mill

Indlela Ohlukumeza Ngayo End Mill

Izigayo zokuphela kwe-Carbide zimelana nokushisa ngokwedlulele futhi zisetshenziselwa izinhlelo zokusebenza ezinesivinini esikhulu kwezinye zezinto eziqinile njengensimbi ekhonjiwe, izinsimbi ezingenayo insimbi, ama-alloys, namapulasitiki. Kodwa ingabe uyazi ukuthi impilo yesevisi ye-milling cutter izothinteka uma ingasetshenziswa kahle? Nazi ezinye izici okufanele uzikhathalele.

1. Wacosha umshini wokugaya ongafanele.

I-Carbide end Mill enezimbotshana ingakhuphula ukuthambisa, kanye nokugqokwa kwamathuluzi emvelo ahamba kancane, kuyilapho amanye angakhuphula ubulukhuni nokungabambeki kwemihuzuko. Kodwa-ke, akuwona wonke ama-coatings afaneleka kuzo zonke izinto zokwakha, futhi umehluko ubonakala kakhulu ezintweni ezinsimbi nezingenayo insimbi. Isibonelo, i-Aluminium Titanium Nitride (AlTiN) enamathelayo inyusa ubulukhuni nokumelana nezinga lokushisa ezintweni ezisansimbi kodwa inokusondelana okuphezulu ne-aluminium, okubangela ukunamathela kocezu lokusebenza ethuluzini lokusika. Ngakolunye uhlangothi, i-Titanium Diboride (TiB2) enamathelayo inokusondelana okuphansi kakhulu kwe-aluminium, ivimbela ukwakheka okuphambili kanye nokupakishwa kwe-chip, futhi inweba impilo yamathuluzi.

2. Ukusebenzisa ubude obude bokusika ngendlela engafanele.

Nakuba ubude obude bokusika buyadingeka kweminye imisebenzi, ikakhulukazi ekuqedeni imisebenzi, kunciphisa ukuqina namandla ethuluzi lokusika. Njengomthetho ojwayelekile, ubude bethuluzi lokusika kufanele bube isikhathi eside njengoba kudingekile ukuze kuqinisekiswe ukuthi ithuluzi ligcina ingxenye yalo yokuqala eningi ngangokunokwenzeka. Lapho ubude bethuluzi bokusikwa buthatha isikhathi eside, kuba lula ukuphambuka, bese kuncipha impilo yamathuluzi asebenzayo futhi kwandise amathuba okuphuka.

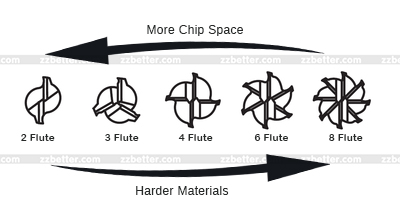

3. Ukukhetha umtshingo ongafanele.

Isibalo somtshingo wethuluzi sinomthelela oqondile futhi ophawulekayo ekusebenzeni kwawo namapharamitha asebenzayo. Nokho, izinga eliphezulu lomtshingo alihlali lingcono. Izibalo zomtshingo eziphansi zivame ukusetshenziswa kuzinto ze-aluminiyamu nezingezona ayoni, ngenxa yokuthi ukuthamba kwalezi zinto kuvumela ukuguquguquka okwengeziwe kwamazinga akhuphukayo okususwa kwensimbi kodwa nangenxa yezakhiwo zama-chips azo. Izinto ezingezona insimbi ngokuvamile zikhiqiza ama-chips amade, ama-stringier, kanye nenani eliphansi lomtshingo lisiza ukunciphisa ukusika kabusha kwe-chip. Amathuluzi wokubala umtshingo ophezulu ngokuvamile ayadingeka ezintweni ezisansimbi eziqinile, kokubili ngenxa yamandla azo akhulayo futhi ngenxa yokuthi ukunqanyulwa kwe-chip akuyona into ekhathazayo njengoba lezi zinto zivame ukukhiqiza amashiphu amancane kakhulu.

Sisebenza ngokukhethekile ekukunikezeni izigayo zekhwalithi ephezulu ze-carbide futhi sisekela isevisi yomhlaba wonke yokulethwa okusheshayo ye-oda lakho.

Uma unentshisekelo kumishini yokuphela kwe-tungsten carbide futhi ufuna ulwazi olwengeziwe kanye nemininingwane, UNGATHINTA NGOcingo noma ngemeyili kwesokunxele, noma SITHUMELE I-MEyili ezansi ekhasini.