Yadda Ake Samar da Masu yankan PDC

Yadda ake samar da masu yankan PDC

General Electric (GE) ne ya fara ƙirƙira PDC Cutter a cikin 1971. An ƙaddamar da shi ta kasuwanci a cikin 1976 bayan an tabbatar da shi sosai fiye da murkushe ayyukan maɓalli na carbide. PDC bits yanzu sun mamaye fiye da kashi 90% na jimillar faifan hakowa a duniya. Amma kun san yadda ake samar da masu yankan PDC? Ina so in raba wasu bayanai tare da ku anan.

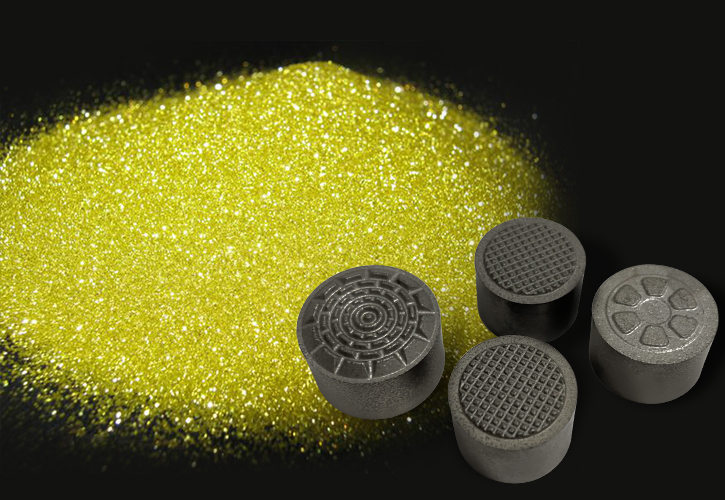

Kayayyaki

zaɓi lu'u-lu'u mai ƙima, murkushe shi kuma sake siffata shi, yana sa girman barbashi ya zama iri ɗaya, yana tsarkake kayan lu'u-lu'u. Domin tungsten carbide substrate muna amfani da babban ingancin budurwa foda da kuma dace carbide sa tare da babban tasiri juriya.

Farashin HTHP

1. ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kayan aiki don samar da masu yanke PDC

2. duba zafin jiki da matsa lamba a cikin ainihin lokaci kuma daidaita cikin lokaci. Zazzabi shine 1300-1500℃. Matsakaicin shine 6-7 GPA.

3. Samar da yanki ɗaya na PDC Cutters zai buƙaci kusan mintuna 30 gabaɗaya.

Farko guda dubawa

Kafin samar da taro, duba yanki na farko don ganin ko ya dace da buƙatun abokin ciniki don girma da aiki.

Nika

1. girma nika: nika waje diamita da tsawo. yi amfani da injin niƙa na silinda don yin niƙa na waje zuwa billet ɗin samfur. Saboda kayan na iya canzawa yayin babban matsi mai girma da haɓakar zafin jiki, samfurin da aka samu bazai da cikakkiyar siffar kuma ya dace da buƙatun bayyanar samfur, kuma dole ne a sami cikakkiyar silinda ta hanyar niƙa na waje.

2. chamfer nika: chamfer ya kamata ya zama kusan 0.1-0.5mm tare da kusurwa na 45; dachamfer na iya zama ƙasa zuwa digiri daban-daban daidai da buƙatun abokin ciniki.

Dubawa na ƙãre kayayyakin

Don tabbatar da duk masu yankan PDC sun cancanta kuma sun daidaita, ya kamata mu bincika masu yankan PDC na ƙarshe. Ya kamata a gudanar da binciken abubuwa kamar bayyanar, girma, da aikin jiki, sannan a rarraba da tattara samfuran bayan an duba su don cancanta. Wannan muhimmin mataki ne don tabbatar da ingancin samfur; Ya kamata a jaddada ma'aunin kauri na lu'u-lu'u polycrystalline yayin binciken samfurin.

Shiryawa

Ya kamata bayyanar da girman samfurin mai fita ya dace da ma'auni na masana'antu, bugu da ƙari, bayyanar samfurin da girma bai kamata ya canza ba yayin sufuri mai nisa. Da farko a cikin akwatin filastik, sannan a cikin kwali. 50 a cikin kowane akwatin filastik.

A ZZbetter, za mu iya bayar da fadi da kewayon takamaiman cutters.