Cov lus qhia luv luv ntawm PDC laum ntsis

Cov lus qhia luv luv ntawm PDC laum ntsis

Polycrystalline pob zeb diamond compact (PDC) laum cov khoom yog tsim nrog cov khoom siv pob zeb diamond cutters nyob rau hauv cov hlau los yog matrix lub cev khoom.PDC laum cov khoom hloov pauv kev lag luam drilling nrog ntau daim ntawv thov ntau yam thiab muaj peev xwm nkag siab (ROP) siab.

PDC Bits yog tsim thiab tsim raws li:

§Matrix-lub cev me ntsis

§Steel-lub cev khoom

MATRIX-IB

Matrix yog ib qho nyuaj thiab nkig sib xyaw cov khoom uas muaj tungsten carbide nplej metallurgically sib raug zoo nrog softer, tougher, metallic binder. Nws yog erosion-resistant ntau dua li hlau. Lawv nyiam nyob rau hauv cov ntsiab lus siab-cov ntsiab lus drilling av nkos.

Qhov zoo-

1. Matrix yog qhov tsim nyog raws li cov khoom me me ntawm cov hlau vim tias nws cov tawv tawv tuaj yeem tiv taus xeb thiab yaig.

2. Nws muaj peev xwm tiv taus qhov hnyav hnyav.

3. Rau cov pob zeb diamond-impregnated khoom, tsuas yog siv cov matrix-lub cev siv tau.

Qhov tsis zoo-

1. Piv nrog cov hlau, nws muaj qhov tsis zoo rau kev cuam tshuam kev thauj khoom.

2. Qhov cuam tshuam qis dua ntawm lub matrix txwv qee qhov matrix-ntsis nta, xws li hniav qhov siab.

STEEL-lub cev

Hlau yog metallurgically opposite ntawm matrix. Steel bodied khoom feem ntau nyiam rau cov mos mos thiab tsis-abrasive formations thiab loj qhov loj. Txhawm rau txo qhov kev yaig ntawm lub cev me ntsis, cov khoom siv tawv tawv nrog cov khoom siv txheej txheej uas tiv taus corrosion ntau dua thiab qee zaum tau txais kev kho mob los tiv thaiv pob zeb rau cov pob zeb nplaum heev xws li shales.

Qhov zoo-

1. Cov hlau yog ductile, tawv, thiab muaj peev xwm tiv taus kev cuam tshuam ntau dua.

2. Nws muaj peev xwm tiv taus qhov hnyav hnyav, tab sis kuj yog mos thiab, tsis muaj kev tiv thaiv, yuav ua tsis tau sai los ntawm kev puas tsuaj thiab yaig.

3. Vim tias cov khoom siv steel muaj peev xwm, cov txheej txheem me me thiab cov qauv hydraulic tau ua tau thiab yooj yim rau kev tsim ntawm ntau lub axis, lub tshuab computer-ntaus tswj milling.

Qhov tsis zoo-

1. Lub cev hlau tsis tshua muaj kev yaig-resistant dua li cov matrix thiab, yog li ntawd, muaj kev cuam tshuam ntau dua los ntawm cov kua dej abrasive.

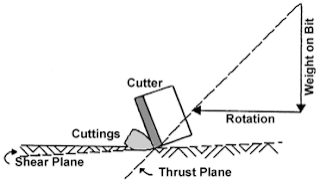

PDC cov khoom xyaum feem ntau yog shearing. Lub zog ntsug nkag los ntawm kev siv qhov hnyav ntawm me ntsis thiab kab rov tav quab yuam los ntawm lub rooj teb yog xa mus rau hauv cov cutters. Lub resultant quab yuam txhais lub dav hlau ntawm thrust rau lub cutter. Cuttings yog txiav tawm ntawm qhov pib lub kaum sab xis ntawm lub dav hlau ntawm thrust, uas yog nyob ntawm pob zeb lub zog.

Daim ntawv thov dav rau PDC cov khoom yuav tsum tau tshwj xeeb PDC cutter thev naus laus zis kom tau txais txiaj ntsig zoo tshaj plaws hauv txhua daim ntawv thov. Optimal cutter portfolio yuav ua kom muaj kev ua tau zoo tshaj plaws hauv txhua qhov kev sib tw drilling.

Tiv tauj peb ntawmwww.zzbetter.comYog xav paub ntxiv txog peb PDC cutter rau PDC laum ntsis.