Kev tswj zoo ntawm PDC cutters

Kev tswj zoo ntawm PDC cutters

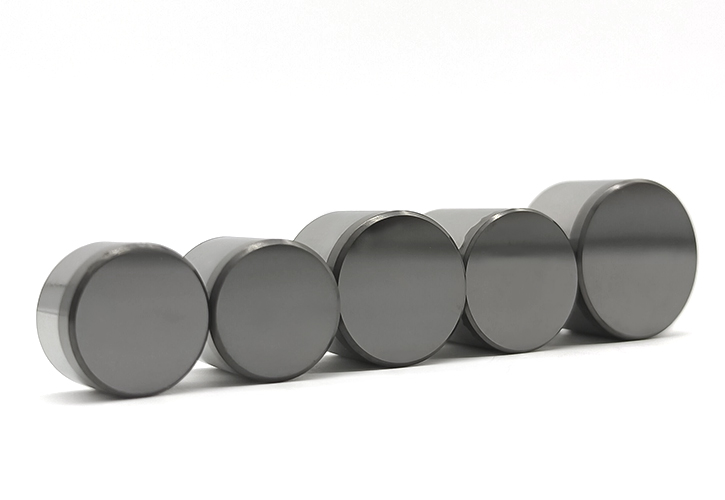

PDC cutters muaj Polycrystalline Pob zeb diamond txheej thiab carbide substrate. PDC cutters tseem hu ua Polycrystalline Pob zeb diamond Compact cutters, uas yog ib hom khoom siv tawv heev. Kev siv polycrystalline pob zeb diamond compact (PDC) cutters yog dav dav niaj hnub no vim lawv cov kev ua tau zoo thiab ua haujlwm ntev hauv qhov chaw hnyav.

Qhov tseem ceeb tshaj plaws rau PDC cutters hauv oilfield drilling daim ntawv thov yog qhov zoo thiab sib xws. Kuv ntseeg tias sawv daws yuav pom zoo. Tab sis yuav ua li cas tswj qhov zoo?

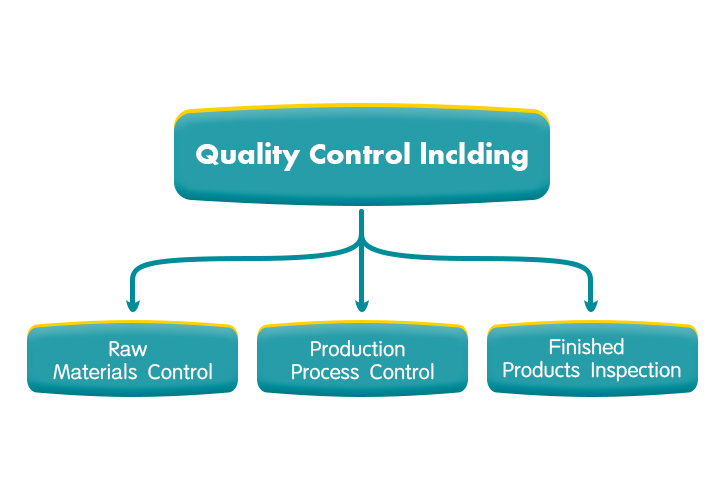

Txhawm rau kom ntseeg tau tias txhua daim PDC cutter tuaj txog ZZZoo duacov neeg siv khoom txhais tes nrog cov khoom zoo, ZZZoo duatau tsim kom muaj kev tswj xyuas nruj, suav nrog kev tswj cov khoom siv raw, kev tswj cov txheej txheem ntau lawm, thiab kev tswj cov khoom tiav. Peb cov neeg ua haujlwm tau txais kev cob qhia zoo thiab muaj kev tshaj lij thiab mob siab rau. Txhua PDC cutter yog tsim los nrog cov neeg ua haujlwm tau txais kev cob qhia thiab kev tswj xyuas lub siab ntawm presses thaum sintering.

PDC cutter zoo tswj:

1. Cov khoom nyoos

2. Cov txheej txheem ntau lawm

3. Kev tshuaj xyuas cov khoom tiav

1. Raw khoom tswj

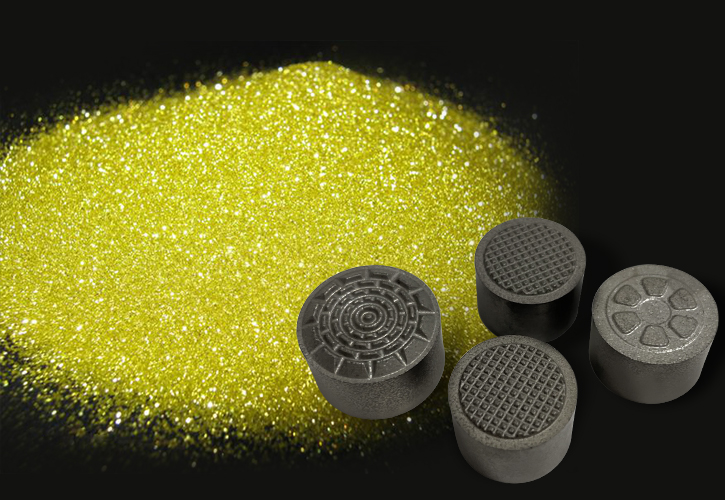

1.1 Rau kev ua PDC cutter oilfield drilling daim ntawv thov peb siv cov pob zeb diamond txawv teb chaws. Peb kuj yuav tsum tau zuaj thiab ua kom nws rov zoo dua, ua rau cov particle loj dua qub. Peb kuj yuav tsum tau ntxuav cov khoom siv pob zeb diamond.

1.2 Peb siv Laser Particle Size Analyzer los tshuaj xyuas qhov loj me me, purity thiab loj rau txhua pawg pob zeb diamond hmoov.

1.3 Rau tungsten carbide substrate peb siv qib zoo nrog rau kev ua haujlwm siab.

2. Cov txheej txheem ntau lawm

2.1 Peb muaj cov kws tshaj lij thiab cov chaw tshaj lij los tsim PDC cutters

2.2 Thaum lub sijhawm tsim khoom peb yuav kuaj xyuas qhov kub thiab txias hauv lub sijhawm tiag tiag thiab kho lub sijhawm. Qhov kub yog 1300-1500℃. Lub siab yog 6 - 7 GPA. Nws yog HTHP nias.

Rau kev tsim ib daim ntawm PDC Cutters yuav tsum tau nyob ib ncig ntawm 30 feeb nyob rau hauv tag nrho.

Rau txhua pawg ntawm PDC cutters, thawj daim yog qhov tseem ceeb heev. Ua ntej qhov ntau lawm, peb yuav tshuaj xyuas thawj daim kom pom seb nws puas ua tau raws li cov neeg siv khoom xav tau rau qhov loj me thiab kev ua tau zoo.

3.Kev tshuaj xyuas cov khoom tiav

Txhawm rau kom txhua tus PDC cutters tsim nyog thiab zoo ib yam, peb yuav tsum tsis yog nruj me ntsis tswj cov ntaub ntawv raw kev tshuaj xyuas thiab kev tswj cov khoom ntws thiab kev txhim kho cov txheej txheem, peb kuj yuav tsum tau cog lus los tsim lub chaw soj ntsuam nrog cov chaw sim siab heev kom ua raws li cov txheej txheem drilling thiab sim PDC cutters ntawm lub Hoobkas. ua ntej xa mus rau peb cov neeg siv khoom.

Rau kev tswj cov khoom tiav peb yuav ua los ntawm cov hauv qab no:

Kev tshuaj xyuas qhov loj thiab qhov pom

Internal tsis xws luag tswj

Kev xeem ua haujlwm

3.1 Kev tshuaj xyuas qhov loj thiab qhov pom:txoj kab uas hla, qhov siab, pob zeb diamond thickness, chamfer, qhov ntau thiab tsawg geometric, tawg, qhov chaw dub, thiab lwm yam.

3.2 Internal defects tswj

Rau kev tswj tsis raug sab hauv peb yuav siv cov khoom siv tshuaj ntsuam xyuas ultrasonic C-san siab heev. Rau cov roj foob PDC cutters peb yuav tsum luam tawm txhua daim.

Nrog C-scanning system, ultrasonic nthwv dej tuaj yeem nkag mus rau PDC txheej thiab kuaj pom nws qhov delamination lossis kab noj hniav tsis zoo. C-scanning system tuaj yeem pom qhov loj thiab txoj haujlwm ntawm qhov tsis xws luag thiab qhia lawv ntawm PC screen. Nws yuav siv sijhawm li 20 feeb los kuaj xyuas ib zaug.

3.3 PDC Cutter qhov kev ua tau zoo sampling test:

hnav tsis kam

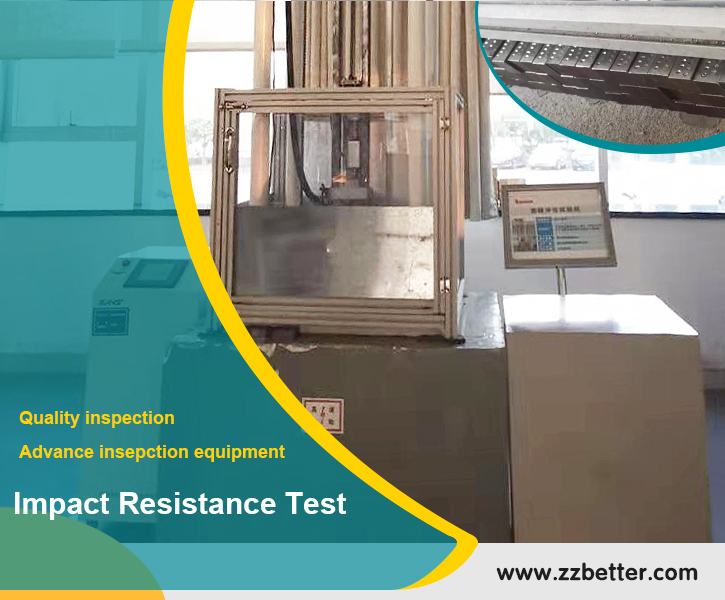

cuam tshuam tsis kam

thermal stability.

3.3.1 Wear Resistance Testing:los ntawm kev ntsuas pes tsawg qhov hnyav poob tom qab PDC cutters av granite nyob rau hauv ib lub sij hawm ntawm lub sij hawm, peb tau txais ib tug hnav-off piv. Nws yog qhov poob loj ntawm PDC cutters thiab granite. Qhov siab dua qhov piv, qhov hnav tsis kam PDC Cutters yuav ntau dua.

3.3.2Kev cuam tshuamKev Ntsuas Kev Ntsuas:Peb kuj hu nws Drop-Weight test, siv lub tshuab dhos ntsug ntawm qee qhov siab hammering mus rau PDC Cutter txiav profile, feem ntau muaj qee qhov degree (15-25 degree) swb. Qhov hnyav ntawm lub tshuab dhos ntsug thiab nws qhov siab preset yuav qhia tias qhov cuam tshuam tiv thaiv qhov PDC cutter yuav ua li cas.

3.3.3 Thermal Stability Test:Nws yog tsom rau kev sim yog tias PDC Cutters muaj thermal ruaj khov txaus nyob rau hauv qhov kub thiab txias ua haujlwm. Hauv chav kuaj, peb muab PDC cutters hauv qab 700-750℃nyob rau hauv 10-15 feeb thiab tshuaj xyuas pob zeb diamond txheej mob tom qab ntuj txias hauv huab cua. Feem ntau cov txheej txheem no yuav nrog rau lwm qhov hnav tsis kam thiab cuam tshuam rau kev sib piv PDC cutter qhov zoo ua ntej kuaj thiab tom qab kuaj.

Txais tos kom ua raws peb lub tuam txhab nplooj ntawv:https://lnkd.in/gQ5Du_pr

Kawm ntxiv:WWW.ZZBETTER.COM