Yuav Ua Li Cas Txiav Tungsten Carbide Qws?

Yuav Ua Li Cas Txiav Tungsten Carbide Qws?

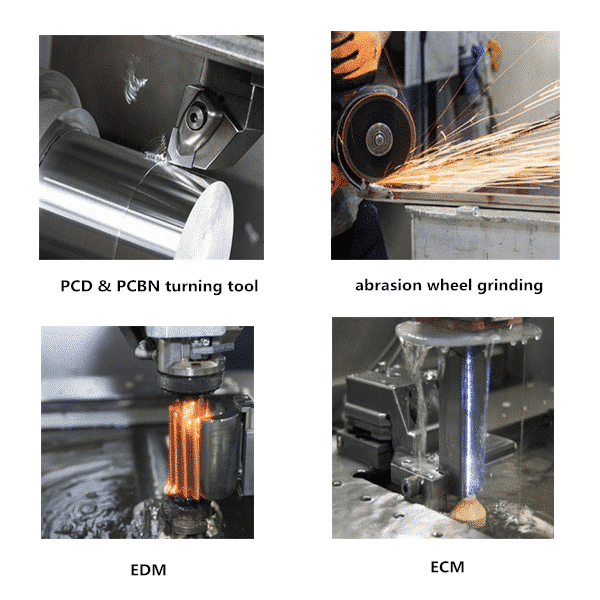

Peb paub tias lub hardness ntawm cov cuab yeej siv nws tus kheej yuav tsum siab tshaj qhov hardness ntawm lub workpiece yuav tsum machined. Rockwell hardness ntawm cemented carbide feem ntau nyob ib ncig ntawm HRA78 txog HRA90. Yog tias koj xav tau qhab nia lossis txiav tawm tungsten carbide rods zoo, 4 txoj hauv qab no tuaj yeem ua haujlwm, uas yog kev sib tsoo log, kev ua haujlwm los ntawm cov khoom siv tawv tawv, electrolytic machining (ECM), thiab hluav taws xob tawm machining (EDM).

1. Txiav carbide pas nrig los ntawm lub log sib tsoo

Txij li tam sim no, cov ntaub ntawv uas tuaj yeem ua cov carbide blanks feem ntau yog xa mus rau poly-crystalline cubic boron nitride (PCBN) thiab poly-crystalline pob zeb diamond (PCD).

Cov ntaub ntawv tseem ceeb rau kev sib tsoo log yog ntsuab silicon carbide thiab pob zeb diamond. Txij li kev sib tsoo ntawm silicon carbide yuav ua rau muaj kev ntxhov siab ntau tshaj qhov kev txwv lub zog ntawm cov cemented carbide, cov kab nrib pleb tshwm sim ntau heev, uas ua rau silicon carbide tsis yog qhov kev xaiv zoo tshaj plaws los ua qhov chaw uas tuaj yeem lav tau.

Txawm hais tias PCD sib tsoo lub log yog tsim nyog ua tiav tag nrho cov dej num los ntawm kev ntxhib los ua kom tiav ntawm carbide blanks, txhawm rau txo qhov poob ntawm kev sib tsoo log, carbide blanks yuav ua ntej ua tiav los ntawm txoj kev siv hluav taws xob, tom qab ntawd ua tiav ib nrab thiab nplua- ua tiav los ntawm kev sib tsoo lub log thaum kawg.

2. Txiav carbide bar los ntawm milling thiab tig

Cov ntaub ntawv ntawm CBN thiab PCBN, npaj los ua ib txoj hauv kev los txiav cov hlau dub nrog cov tawv tawv, xws li cov hlau tawv tawv thiab cov hlau cam (hlau). Boron nitrite muaj peev xwm tiv taus qhov kub thiab txias ntawm qhov cuam tshuam (siab dua 1000 degrees) thiab tuav hardness ntawm 8000HV.Qhov khoom no ua rau nws sib npaug rau kev ua cov carbide blanks, tshwj xeeb tshaj yog rau cov qauv tsim muaj xws li carbide core thiab steel casing nyob rau hauv ib qho kev cuam tshuam haum.

Txawm li cas los xij, thaum lub hardness ntawm cemented carbide qhov siab siab dua HRA90, tag nrho tawm ntawm boron nitrite cov pab koomtes txiav, tsis tas yuav hais ntxiv rau PCBN thiab CBN cov cuab yeej.peb tuaj yeem tig mus rau pob zeb diamond PCD cutters los hloov raws li qhov xwm txheej no.

Peb tseem tsis tuaj yeem pom qhov tsis zoo ntawm PCD ntxig, nws tsis muaj peev xwm kom tau txais cov npoo ntse heev thiab qhov tsis yooj yim los tsim cov chipbreakers. Yog li, PCD tsuas yog siv tau rau kev txiav cov hlau tsis muaj hlau thiab cov hlau tsis muaj hlau, tab sis tsis tuaj yeem ua tiav ultra-precision iav-txiav ntawm carbide blanks, tsawg kawg tseem tsis tau.

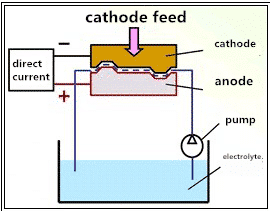

3. Electrolytic Machining (ECM)

Electrolytic processing yog kev ua haujlwm ntawm cov khoom los ntawm lub hauv paus ntsiab lus uas carbide tuaj yeem yaj hauv electrolyte (NaOH). Nws xyuas kom meej tias qhov chaw ntawm carbide workpiece tsis tau cua sov. Thiab lub ntsiab lus yog tias ECM kev ua haujlwm ceev thiab kev ua haujlwm zoo yog ywj siab ntawm lub cev ntawm cov khoom yuav tsum tau ua.

4. Hluav taws xob tawm machining (EDM)

Lub hauv paus ntsiab lus ntawm EDM yog raws li qhov tshwm sim ntawm hluav taws xob corrosion ntawm lub cuab yeej thiab lub workpiece (zoo thiab tsis zoo electrodes) thaum lub sij hawm pulse txim tawm kom tshem tawm cov carbide ntau dhau los ua kom tau raws li qhov yuav tsum tau ua ua ntej rau qhov loj, cov duab thiab qhov zoo ntawm lub workpiece. . Tsuas yog tooj liab-tungsten electrodes thiab tooj liab-nyiaj electrodes tuaj yeem ua cov carbide blanks.

Nyob rau hauv luv luv, EDM tsis siv txhua yam lub zog, tsis nyob ntawm txiav quab yuam kom tshem tawm cov hlau, tab sis ncaj qha siv hluav taws xob lub zog thiab cua sov kom tshem tawm cov carbide ib feem.