Vim li cas stainless hlau cov ntaub ntawv nyuaj rau txheej txheem?

Vim li cas stainless hlau cov ntaub ntawv nyuaj rau txheej txheem?

Stainless hlau, Ameslikas hu ua rustless steel, yog ib qho ntawm ib pawg ntawm ferrous alloys uas muaj qhov tsawg kawg nkaus ntawm kwv yees li 11% chromium, muaj pes tsawg leeg uas tiv thaiv cov hlau los ntawm xeb thiab kuj muab cov khoom cua sov.

Piv nrog rau cov "mos" hlau xws li txhuas, stainless hlau yog qhov nyuaj heev rau tshuab. Qhov no yog vim cov hlau tsis muaj hlau yog cov hlau alloy uas muaj zog thiab zoo plasticity. Thaum lub sij hawm machining txheej txheem, cov khoom yuav nyuaj thiab ua kom muaj cua sov ntau. Qhov no ua rau cov cuab yeej txiav nrawm dua. Ntawm no yog 6 lub ntsiab yog vim li cas:

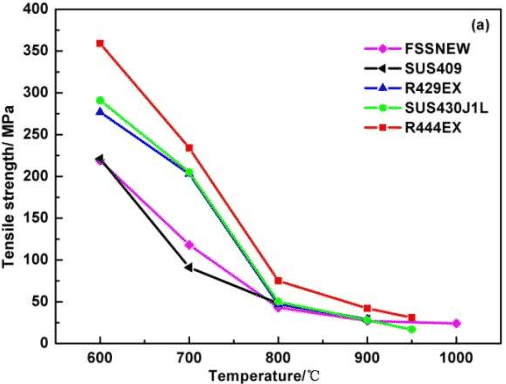

1. Kev kub siab lub zog thiab kev ua haujlwm hardening nyiam

Piv nrog rau cov hlau zoo tib yam, stainless hlau muaj lub zog nruab nrab thiab hardness. Txawm li cas los xij, nws muaj ntau cov ntsiab lus xws li Cr, Ni, thiab Mn, thiab muaj cov yas zoo thiab cov tawv tawv, lub zog kub, thiab kev ua haujlwm siab ua haujlwm siab uas yog li ua rau cov khoom txiav. Tsis tas li ntawd, nyob rau hauv austenitic stainless hlau thaum lub sij hawm txiav cov txheej txheem, ib co carbide yog precipitated nyob rau hauv, uas ua rau kom cov nyhuv khawb ntawm lub cutter.

2. Loj txiav quab yuam yuav tsum tau

Stainless hlau muaj cov yas loj deformation thaum txiav, tshwj xeeb tshaj yog austenitic stainless hlau (lub elongation ntau tshaj 1.5 npaug ntawm 45 steel), uas ua rau kom cov txiav quab yuam.

3.Chip thiab cov cuab yeej sib txuas phenomenon yog ib yam

Nws yog ib qho yooj yim rau kev tsim-up ntug thaum txiav, uas cuam tshuam rau qhov chaw roughness ntawm machined nto thiab yooj yim ua rau saum npoo ntawm cov cuab yeej tev tawm.

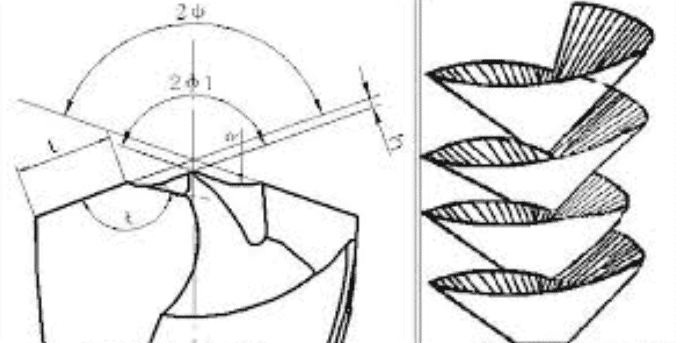

4. Cov nti yog ib qho yooj yim rau curl thiab tawg

Rau kaw thiab semi-kaw chip cutters, nti clogging yog ib qho yooj yim rau tshwm sim, ua rau muaj zog nto roughness thiab cov cuab yeej chipping

Fig.2. Qhov zoo tshaj plaws nti zoo ntawm stainless hlau

5. Qhov loj coefficient ntawm linear expansion

Nws yog kwv yees li ib thiab ib nrab npaug ntawm cov kab tawm nthuav dav coefficient ntawm carbon steel. Nyob rau hauv qhov kev txiav txim ntawm qhov kub thiab txias, lub workpiece yog ua rau thermal deformation thiab cuam tshuam rau qhov tseeb qhov tseeb.

6. Me me thermal conductivity

Feem ntau, nws yog hais txog 1/4 ~ 1/2 ntawm thermal conductivity ntawm nruab nrab carbon steel. Qhov ntsuas kub yog siab thiab lub cuab yeej hnav nrawm.

Yuav ua li cas rau machining stainless hlau?

Raws li peb cov kev coj ua thiab kev paub dhau los, peb ntseeg tias cov lus qhia hauv qab no yuav tsum tau ua raws li cov khoom siv stainless hlau machining:

1. Kev kho cua sov ua ntej machining, Cov txheej txheem kev kho cua sov tuaj yeem hloov qhov hardness ntawm stainless hlau, ua rau nws yooj yim rau tshuab.

2.Kev lubrication zoo heev, Cov dej txias lubricating tuaj yeem tshem tawm cov cua sov ntau thiab lubricate cov khoom saum npoo tib lub sijhawm. Peb feem ntau siv cov roj nplaum sib xyaw ua ke ntawm nitrogen tetrafluoride thiab cov roj cav. Kev xyaum tau ua pov thawj tias cov roj nplua nyeem no yog qhov tsim nyog rau kev ua haujlwm tsis muaj steel hlau nrog cov npoo du.

3.Siv cov cuab yeej txiav cov cuab yeej zoo kom tau qhov chaw du thiab kam rau me me thaum txo lub sij hawm hloov cov cuab yeej.

4. Tsawg txiav ceev. Xaiv qhov kev txiav qis qis tuaj yeem txo qhov tsim hluav taws xob thiab pab txhawb kev tawg.

Xaus

Tag nrho cov nyob rau hauv tag nrho, stainless hlau yog ib qho ntawm cov khoom nyuaj tshaj plaws rau tshuab. Yog tias lub khw muag khoom muaj peev xwm tshuab aluminium, tooj liab, thiab carbon hlau zoo heev, qhov no tsis txhais tau hais tias lawv tuaj yeem siv cov hlau tsis muaj hlau zoo heev.