Yuav ua li cas txhawm rau txhim kho qhov hnav tsis kam ntawm Carbide Wear Parts?

Yuav ua li cas txhawm rau txhim kho qhov hnav tsis kam ntawm Carbide Wear Parts?

Kev hnav ua haujlwm ntawm tungsten carbide cuam tshuam los ntawm kev siv ib puag ncig thiab kev ua haujlwm ntawm cov hlau. Kev hnav tsis kam yog tsuas yog txiav txim siab los ntawm microstructure thiab tshuaj muaj pes tsawg leeg. Cov txheej txheem tseem ceeb ntawm cov cemented carbide yog cov nplej loj thiab cov ntsiab lus ntawm kev sib koom ua ke. Kev hnav kuj tseem cuam tshuam los ntawm cov khoom ntxiv xws li barium.

Hauv kev tsim khoom, ntau yam khoom siv kho tshuab tseem ceeb thiab lawv cov khoom siv tshuab yog nyob rau hauv qhov hnyav, xws li kev kub ceev, kev kub ceev, kev kub siab, kev ua haujlwm dhau, thiab lwm yam. Yog li ntawd, kev puas tsuaj rau cov khoom siv kho tshuab feem ntau tshwm sim vim hnav, corrosion, thiab oxidation, uas feem ntau tshwm sim los ntawm qhov chaw.

Cov kev tiv thaiv saum npoo yog siv los ncua thiab tswj kev puas tsuaj, uas tau dhau los ua ib txoj hauv kev zoo rau kev daws qhov hnav ntawm cov khoom siv kho tshuab. Yog li ntawd, ntau yam txheej txheem abrasion nto rau cov khoom siv kho tshuab tau txais, xws li plating, thermos, carburizing, nitriding, permeable hlau, thermal spraying, surfacing, txheej, thiab pasting hardening txheej, siab zog nqaj, thiab lwm yam.

Lub ntiaj teb tsis tshua muaj tau ua tiav hauv cov khoom siv carbide. Thaum lub zog thiab qhov cuam tshuam toughness nce ntau dua 10%, qhov hnav tsis kam ntawm carbide hnav qhov chaw kuj tseem txhim kho.

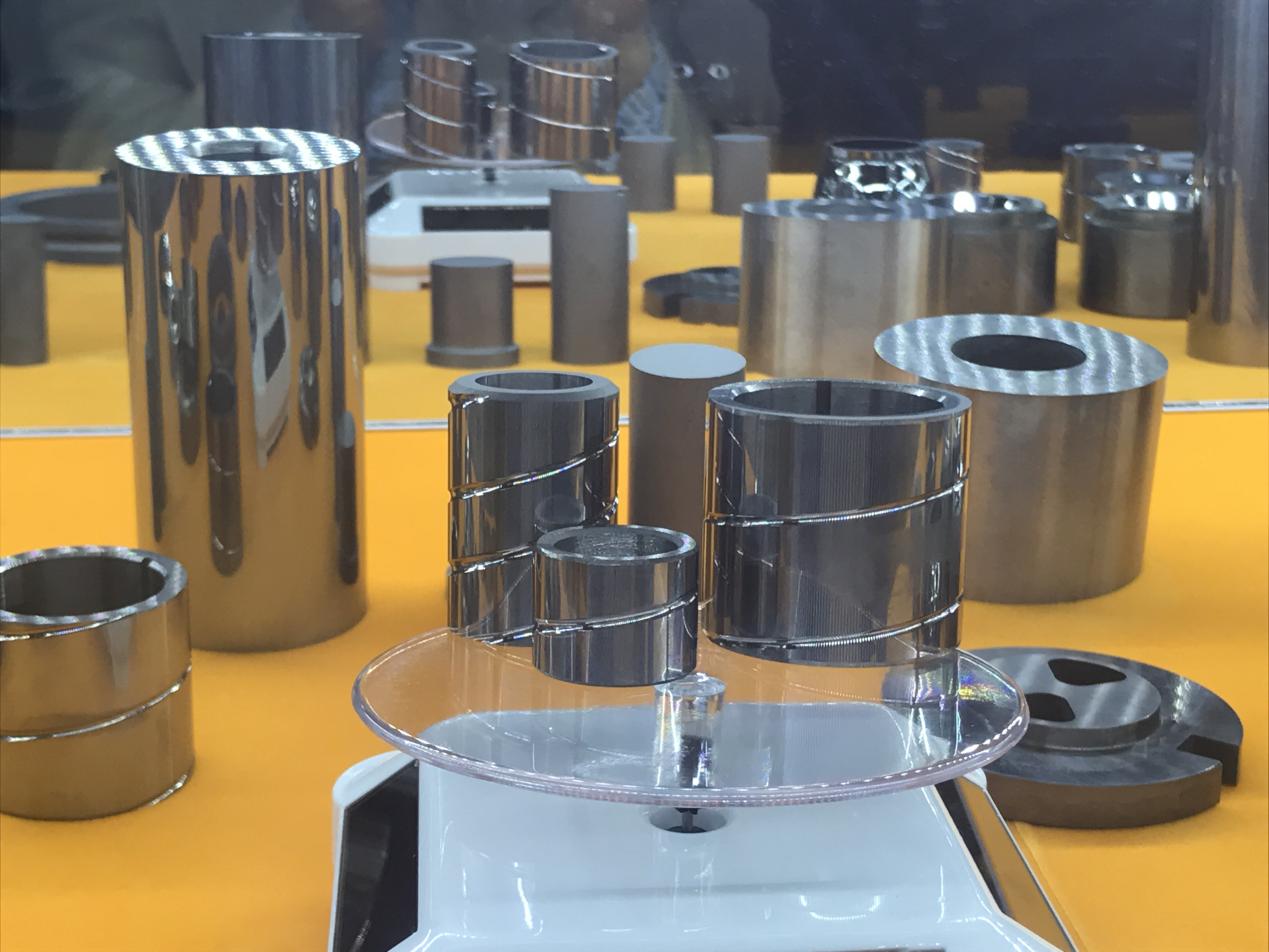

Piv txwv li, tungsten carbide pwm qhov chaw muaj kev ua tau zoo thiab tau siv dav hauv pwm qhov kev lag luam. Txhawm rau kom ua tiav nws cov txiaj ntsig, nws yog ib qho tseem ceeb los txhim kho qhov hnav tsis kam ntawm tungsten carbide pwm qhov chaw.

Feem ntau hais lus, txoj hauv kev zoo tshaj plaws thiab ncaj qha los txhim kho qhov hnav tsis kam ntawm tungsten carbide pwm qhov chaw yog titanium plating ua - lub neej nto, hardening, tus nqi ntxiv thiab hnav tsis kam, corrosion kuj, thiab lwm yam.

Qhov saum npoo ntawm precision hnyav tuag coated nrog lub tshuab nqus tsev txheej tuaj yeem muaj kev sib txhuam coefficient tsawg heev, uas txo cov kev ua haujlwm. Txias stamping thiab kos duab tuag coated nrog lub tshuab nqus tsev txheej tuaj yeem txo kev sib txhuam, khawb, thiab hnav thaum ua haujlwm. Yog li ntawd, nws tuaj yeem ua kom lub neej ntev thiab txo tus nqi ntau.

Qhov zoo:

1. Txo kev sib txhuam coefficient, txo kev ua haujlwm, txhim kho qhov tawv tawv, thiab ua kom lub neej ntev ntev.

2. Hauv kev siv qhov tuag, qhov teeb meem ntawm kev ua tsis tiav thaum ntxov yog feem ntau daws.

3. Ua kom zoo tshaj plaws ntawm cov khoom ua haujlwm kom ua tiav lub luag haujlwm.

4. Ua kom zoo dua qub (xws li nto roughness, raug, thiab lwm yam) thiab kev pab cuam lub neej ntawm pwm qhov chaw, thiaj li ua rau lawv ua si lub peev xwm ntawm cov khoom zoo.

Yog tias koj txaus siab rau cov khoom lag luam tungsten carbide thiab xav paub ntau ntxiv thiab cov ntsiab lus, koj tuaj yeem tiv tauj peb hauv xov tooj lossis xa ntawv ntawm sab laug, lossis xa mus rau US MAIL hauv qab ntawm nplooj ntawv.