Taw qhia ntawm Tungsten Carbide Hlau Drawing Tuag

Taw qhia ntawm Tungsten Carbide Hlau Drawing Tuag

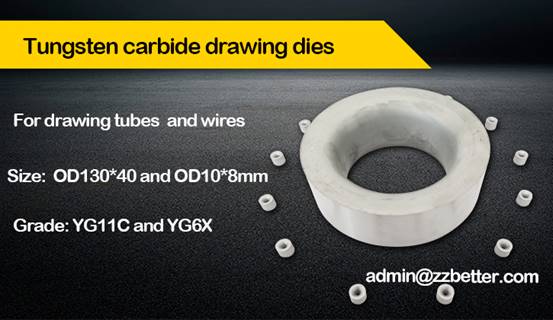

Carbide hlau daim duab tuag txais yuav zoo tungsten carbide ua cov tub ntxhais, uas muaj siab hardness, zoo thermal conductivity, thiab tsis tshua muaj kev sib txhuam coefficient. Tungsten carbide hlau daim duab tuag yog qhov yooj yim los tsim nrog corrosion-resistant, cuam tshuam-resistant, thiab tus nqi qis, uas muaj cov yam ntxwv zoo ntawm cov khoom no. Nws yog qhov tsim nyog rau cov hlau ferrous, cov xaim loj loj, thiab lub sijhawm nrog cov hlau tsis zoo.

Hlau daim duab yog cov txheej txheem tsim los txo lossis hloov cov ntu ntu ntawm cov hlau xaim los ntawm kev siv cov ntawv sib txuas los yog cov pwm. Carbide hlau kos duab tuag yog ib hom tungsten carbide tuag nrog kev siv dav hauv ntau qhov chaw.

YG6X: Tsim nyog rau kev tsim cov carbide tuag nrog kos duab puab qhov uas me duaΦ6.00mm.

YG6: Siv rau cov hlau tsis-ferrous puag ncig bar, uas muaj cov duab puab qhov me dua Φ20mm, thiab cov duab kos tuag, uas muaj qhov sab hauv me dua Φ 10mm.

YG8, YG10: Applied for drawing steel and the production of non-ferrous metal round bars & pipes.

YG15: Siv rau cov pas nrig steel thiab cov kav dej uas muaj qhov shrinkage siab.

Tungsten carbide hlau kos duab tuag muaj cov yam ntxwv hauv qab no uas ua kom lub siab ntev:

1. Muaj zog tsis kam

2. Zoo heev hnav tsis kam

3. Txaus thermal stability

4. Muaj peev xwm ua tau zoo heev

Cov teeb meem xav tau kev saib xyuas thiab kev saib xyuas ntawm carbide hlau kos duab tuag:

1. Ua kom muaj kev ruaj ntseg ntawm lub tshuab kos duab

Rau txhua daim duab nruas, cov lus qhia tshaj kab yuav tsum du, hloov tau, thiab tswj nruj me ntsis rau kev ua siab ntev. Yog tias pom lub nruas, phau ntawv qhia lub log muaj lub trench hnav, thiab cov duab tuag yuav tsum tau kho raws sijhawm.

2. Zoo lubrication

Kev lubrication zoo yog qhov tseem ceeb los xyuas kom meej qhov zoo ntawm cov hlau thiab txuas ntxiv lub neej kev pab cuam ntawm pwm. Lub lubrication Performance index yuav tsum tau xyuas ntau zaus, tshem cov hmoov tooj liab, thiab impurities nyob rau hauv lub lubricant, thiaj li hais tias cov khoom lub qhov yuav tsis polluted. Yog tias lub lubrication tsis ua haujlwm, nws yuav tsum tau hloov lub sijhawm thiab ntxuav.

3. Tsim nyog allotype

Ib qho tsim nyog allotype yog los xyuas kom meej qhov zoo ntawm cov hlau thiab tswj qhov tseeb ntawm qhov loj me, txo qhov hnav ntawm cov hlau nqus nruas thiab cov khoom siv khiav haujlwm. Rau zawv zawg hlau kos tshuab, nws yog ib qho tsim nyog yuav tsum paub koj tus kheej nrog cov khoom siv elongation. Cov zawv zawg coefficient yog tsim nyog xaiv, uas yog thawj kauj ruam ntawm kev haum pwm.

4. Kev kho kom haum ntawm qhov loj rau lub kaum sab xis compression

Tus nqi txo qhov saum npoo ntawm txhua daim duab thiab cov khoom ntawm cov hlau rub tawm kuj zoo sib xws nrog lub kaum sab xis compression ntawm cov pwm. Qhov luaj li cas ntawm lub kaum sab xis compression yog tsim nyog raws li qhov loj ntawm qhov txo tus nqi.

5. Lub sij hawm hloov ntawm cov laus daim duab tuag

Thaum daim duab tuag mus txog qhov kev pab cuam lub neej, thov hloov nws nyob rau hauv lub sij hawm rau kev kho cov kev kho mob kom tsis txhob ntau dhau ua rau seem hlau.

Lub tungsten carbide hlau kos duab tuag yog dav siv rau kev kos duab hauv ntau yam lag luam. Nws muaj cov hardness siab, zoo thermal stability, siab durability, thiab kev pab lub neej ntev thiab yog ib qho ntawm cov khoom pwm zoo tshaj plaws.

Yog tias koj txaus siab rau cov khoom lag luam tungsten carbide thiab xav paub ntau ntxiv thiab cov ntsiab lus, koj tuaj yeem tiv tauj peb hauv xov tooj lossis xa ntawv ntawm sab laug, lossis xa mus rau US MAIL hauv qab ntawm nplooj ntawv.