3 Minutes to Understand ZZbetter PDC Cutters

3 Minutes to Understand ZZbetter PDC Cutters

![]()

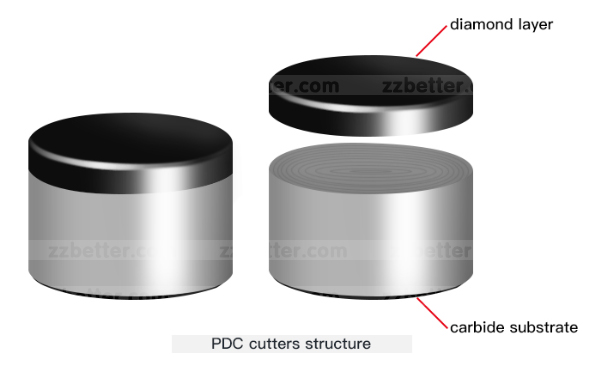

PDC cutter, also named Polycrystalline Diamond Compact cutter, is a kind of super-hard material. The PDC cutter is usually a cylinder with a man-made black diamond cutting face, engineered to withstand the extreme abrasion impact and heat that comes from drilling through rock. The diamond layer and carbide substrate are sintered under ultra-high pressure and ultra-high temperature. The diamond is grown on the carbide substrate, combined with chemical bonding.

Q1:when came to the first piece of PDC cutters?

PDC Cutter was invented first by General Electric (GE) in 1971. The first PDC Cutters for the oil and gas industry were done in 1973 and with 3 years of experimental and field testing, it is introduced commercially in 1976 after it is proven much more efficient than the crushing actions of carbide button bits.

Q2: what’s the application of PDC cutters?

The PDC cutter has the feature of good wear-resistance, impact resistance, and good thermal stability, which is widely used for mining, geological exploration, oil and gas drilling, detail as below:

1. PDC drill bit

2. DTH drill bit

3. Diamond pick

4. Reaming tools

5. Anchor bit

6. Core bit

7. Diamond-bearing element

8. Stone cutting saw blade

Q3: what’s the advantage of PDC cutters?

Compared with a traditional tungsten carbide cutter, the PDC cutter has the following advantages:

1. The service life of a PDC cutter is 6-10 times longer than tungsten carbide, reducing the replacement frequency of the drill bit.

2. Consistent and stable drilling rate effectively protects the construction equipment.

3. PDC cutter has fast footage, and high rock breaking efficiency, which greatly improves drilling efficiency during construction, meanwhile effectively saving drilling cost by 30%-40%.

4. PDC cutters has high wear resistance, ensure the hole size consistency, and also reduce wear of the outer cylinder of the impactor.

Q4: what shape of PDC Cutter does ZZBETTER offer?

1. PDC flat cutter

2. PDC Spherical (dome) button

3. PDC Parabolic button

4. PDC Conical button

5. PDC Square cutters

6. Irregular PDC cutters, like ridged cutter, half-moon cutter, and so on.

Zzbetter has a wide variety of shapes PDC cutters with exceptional performance for down-hole drilling. Whether you are looking for increased ROP, optimized cooling, better depth of cut and formation engagement, or better secondary cutting elements, you can always find solutions at ZZBETTER.

Contact us for the sample at: Irene@zzbetter.com

More info: www.zzbetter.com