Advantages of Tungsten Carbide Segment Dies

Advantages of Tungsten Carbide Segment Dies

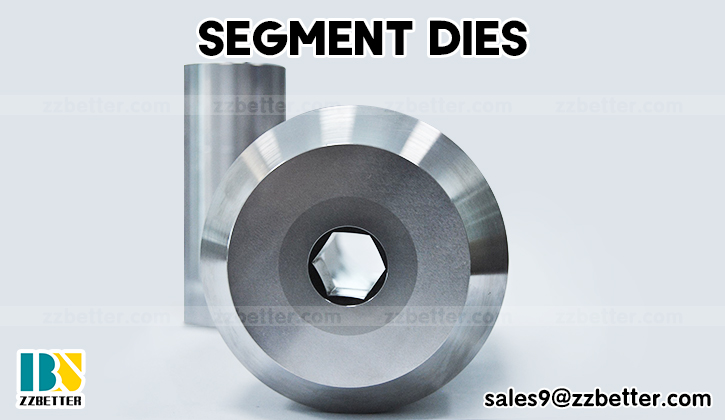

Introducing Segmented Dies

Tungsten carbide segmented die is a typical tablet press die table that is separated into many dies and dies lock screws, each of which needs to be individually installed when setting up a steel jacket. Such segmented die design can reduce the number of components that need installation by splitting the die table into segments. Depending on the type of tablet press needed, each dies only requires 3 to 5 segments, which are secured into place by two fastening bolts. These design characteristics drastically decrease the time and complexity of assembly and disassembly with some facilities saving up to a 70% reduction in setup times.

Applying this segmented design is especially helpful when using shaped dies because it eliminates the need for manual alignment of individual dies. Additionally, the segment provides more consistent alignment, which reduces the risk of human error and the associated costs.

Replacing conventional die tables with our patented segments may also increase production yields. Although highly variable and dependent on your existing tooling, increases in output are possible as employing segments allows machines to accommodate more tablet stations within the same pitch circle diameter.

Advantages of Segmented Dies

When used in place of conventional dies and die lock screws, segmented dies provide several benefits. These include:

Reduced cleaning and setup times. Decreasing the number of individual components reduces the total time spent on installation and removal during setup and cleaning operations.

Increased productivity. Consolidating dies into segments maximizes the use of space between cavities, enabling a greater number of cavities to fit within a turret and, therefore, a higher possible output for each turret.

Improved yield. Segments can achieve smoother station-to-station transition, as the components are formed from a single piece of tool steel and can be installed with zero clearance between themselves and product scrapers. The lack of spacing between these parts improves the efficiency of scrapers and recirculation components, which can increase production yield and reduce the amount of wasted product.

Increased durability. Even standard segments boast a Rockwell hardness level that is significantly higher than that found in conventional die steel. Additionally, segments are available with carbide inserts to increase their durability and wear resistance. The addition of the insert can increase the life span of segments by up to 10 times compared to a standard segment.

Compatibility with existing equipment. Our segmented dies can be integrated into virtually any Fette press manufactured after 1991 without the need for any mechanical or operating software modifications.

Zhuzhou Better Tungsten Carbide Company is a comprehensive tungsten carbide provider for over 15 years. We offer many tungsten carbides die blanks/nibs for dies with jackets.

If you are interested in tungsten carbide rods and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.