How to Weld Snow Plow with Tungsten Carbide

How to Weld Snow Plow with Tungsten Carbide

Keywords: snow plow teeth; tungsten carbide; snow plow shovel; cemented carbide

This article mainly describes the process of snow plow shovel teeth and tungsten carbide welding. First, a square groove for inlaying cemented carbide bars is machined at the top of the shoveling teeth embryo, and auxiliary hydraulic pressure is carried out by shoveling hydraulic welding tools so that the square groove at the top of the shoveling teeth embryo is hydraulically formed into an arc. The bottom surface of the arc groove is low in the middle and high on both sides. Then, the brazing filler metal melting cemented carbide strip and shovel tooth blank material welded into a body to form the shovel teeth, through the medium frequency induction brazing machine for welding.

snow plow shovel teeth are widely used in the wear-resistant front of the snow plow shovel of shovel equipment, requiring high wear resistance and flatness. The existing snow plow shovel teeth are generally made of carbon steel, alloy steel or die steel, which has poor wear resistance and great influence on service life. Carbide has the highest hardness, and the best wear resistance of the material, composed of hardness carbide and alloy, has high wear resistance, but the toughness is poor, and the welding process is easy to crack. Through a large number of experiments, we found that using the existing common welding process will cause steel plate deformation, alloy cracking, and other problems.

Operation steps:

1. Cut the whole ordinary carbon steel plate into the shape of the blank material of the snow plow shovel teeth.

2. At the top of the snow tooth blank, a square groove for inlaying cemented carbide strips is machined.

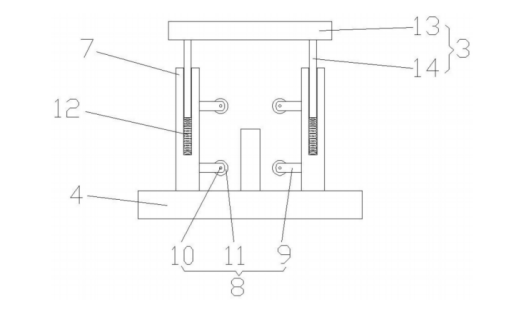

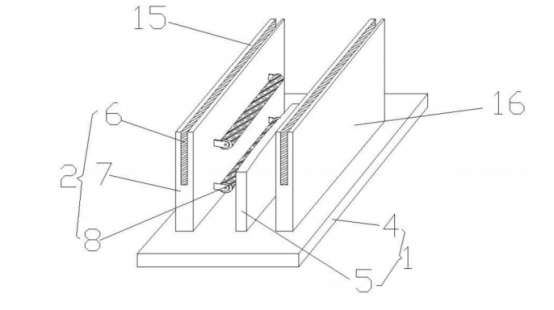

3. Make the shovel gear hydraulic welding tool, put the shovel gear embryo into the shovel gear hydraulic welding tool for hydraulic pressure so that the square groove at the top of the shovel gear embryo is the hydraulic arc groove, the bottom surface of the arc groove is low in the middle and high on both sides of the arc surface.

4. Add the filler metal to the bottom of the arc groove at the top of the snow tooth blank material, and then insert the cemented carbide strip into the arc groove, so that the filler metal is located between the cemented carbide strip and the bottom of the arc groove.

5. The medium frequency induction brazing machine is used for welding, and the cemented carbide strip is connected with the snow plow shovel tooth blank material by melting the brazing metal to form the snow plow shovel tooth.

6. After welding, cool the welded shovel teeth to room temperature.

Conclusion:

To solve the deformation and alloy cracking problems between the shovel teeth and the cemented carbide strip after welding, the invention adopts a novel slotted arc hydraulic welding technology. Firstly, a square groove for inlaying cemented carbide strips is machined at the top of the blank material of the shovel teeth, and auxiliary hydraulic pressure is carried out by the shovel teeth hydraulic welding tool. The square groove at the top of the snow plow shovel tooth embryo is hydraulically formed into an arc groove.

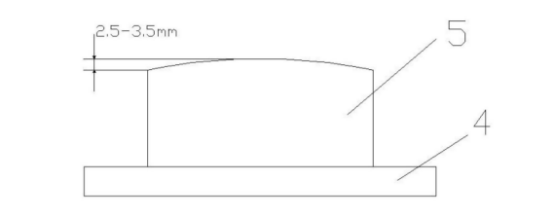

The bottom surface of the arc groove is an arc surface with low middle and high sides. The difference between the lowest point in the middle of the arc surface and the highest point on both sides is 2.5 to 3.5mm. Then through the medium frequency induction brazing machine for welding, through the brazing filler metal melting cemented carbide strip and shovel tooth blank material welded into a body to form the shovel teeth.

Through the slotted arc hydraulic welding process, the deformation amount of the arc groove can be accurately controlled, so that the hydraulic pretension and the welding internal stress of the snow plow shovel tooth embryo and the cemented carbide strip can offset each other, and the reverse deformation amount and the welding deformation amount can offset each other, thus greatly reducing the deformation probability of the snow plow shovel tooth and the welding cracking probability of cemented carbide. At the same time, it also greatly improves the flatness, wear resistance, and service life of the shovel teeth.

The cemented carbide bar welded at the front end of the shovel teeth is an alloy material made of refractory metal and bonded metal through the powder metallurgy process, with high hardness, wear resistance, strength and toughness, heat resistance, corrosion resistance and a series of excellent properties, especially its high hardness and wear resistance, even at 500℃ temperature is basically unchanged.

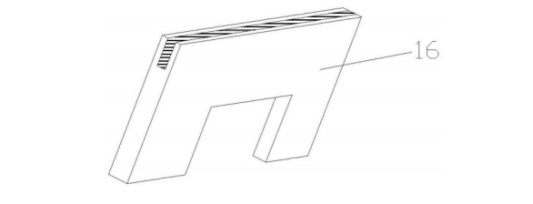

Figure 1

Figure 2

Figure 3

Figure 4

Some contents of this article are quoting and translating from a Chinese report of an Invention patent. Hope this information is helpful to you, and welcome to leave your comments and questions below. ZZBETTER provides various tungsten carbide products at appropriate prices. We are waiting for your inquiry if you need anything related to cemented carbide, just give us your drawings, we can make the right one for you.