Ndeupi Musiyano Pakati Pekuomarara Uye Kuvhara

"Zvakaoma" uye "kupfeka" mazwi maviri anowanzoshandiswa zvakafanana, chaizvo iwo akasiyana maapplication.Hardfacing inzira yewelding inoshandisa nzvimbo yakapfekwa yepamusoro kuwedzera kudzivirira uye kuwedzera hupenyu hwechinhu. ine carbides uye, kazhinji, iyi i cemented carbide.Inoita senge boka rema beads akaiswa pasi padivi nepadivi.

Kuvhara ndiko kuiswa kwesimbi isina kufanana pamusoro peimwe simbi. Kuvhara kunowanzo shandisa zvinhu zvakafukidzwa zvakafanana neyakagadzika zvinhu asi kazhinji zvinoshandisa chimwe chinhu chakasiyana kupa chivakwa chinobatsira kune icho chikamu chechikamu, senge kuomarara kwakanyanya, kusaita ngura, kana kungosangana nebasa rekugadzirisa. Sezvineiwo nekupfeka, laser hardfacing haigone kugadzirwa uye inofanirwa kuvhurika.

Hardfacing VS. Cladding process

Zvakadaro kuomarara uye kuvharika maitiro epamusoro pepamusoro pemaitiro akasiyana mune zvenyama zvinhu zvinosangana nezvinodiwa zvakasiyana, ese ari maviri anogona kuwanikwa uchishandisa maitiro akafanana:

• Ma laser

• Thermal spray

• Flux-cored arc welding kana FCAW

• Plasma Transfer Arc [PTA] welding

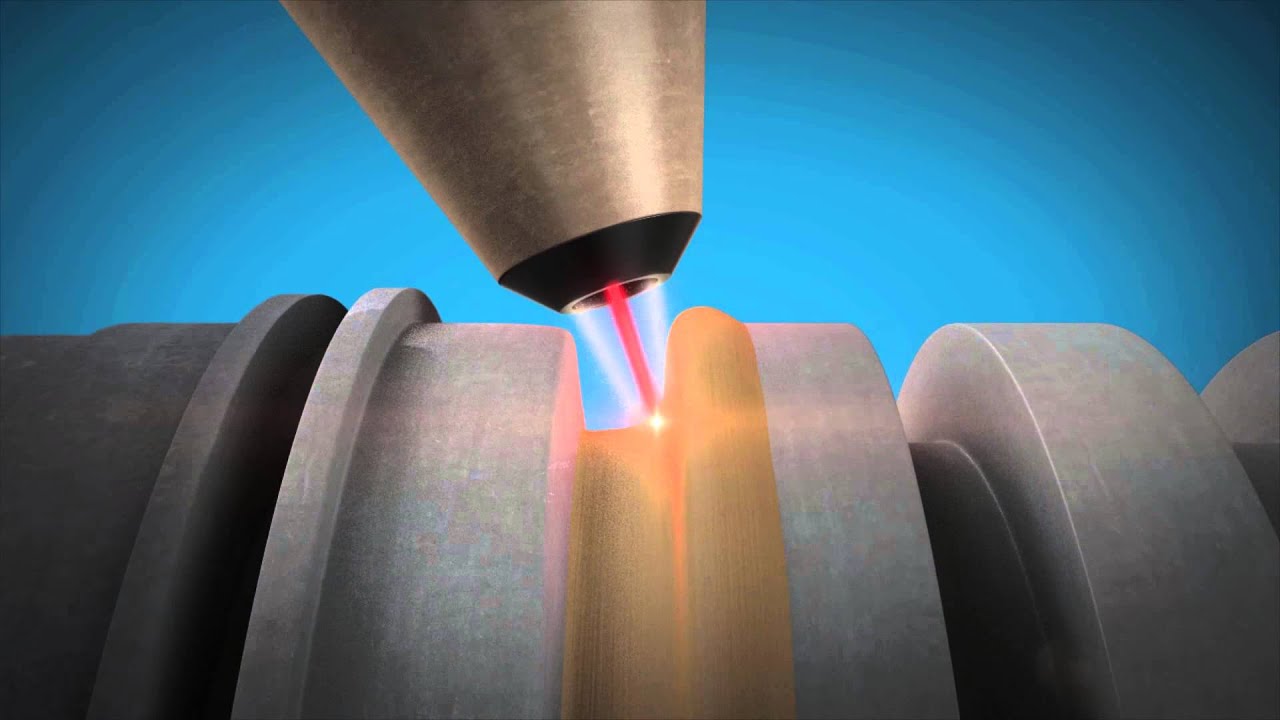

Sarudzo pakati pekuomesera nekupfeka inodzika pasi kune hunhu hwaunoda kupa, zvinhu zvinosanganisirwa, uye nekunzwisisa kwezvakatipoteredza izvo zvepamusoro zvinoiswawo. Mukuomarara, iyo inorema, isingapfekeki-inodzivirira carbide/simbi dhipoziti inogona kuiswa nelaser, kupisa kwemafuta, spray-fuse, kana welding. Kupfapfaidza kwekushisa kwakanakira zvinhu zvinonzwa nekukanganiswa kwekupisa, kusiyana nespray-fuse inoda kupfapfaidza murazvo uye kusanganisa netochi. Thermal spray haisi ye welding process; saka, chisungo simba yakadzikira zvikuru kana zvichienzaniswa neyakaiswa welded kana brazed overlay. Traditional weld hardfacing inogona kushandiswa kuisa dhizaini yakakora (kusvika 10's yemamm) yezvinhu zvisingapfeke. Laser hardfacing ine mabhenefiti pamusoro pemamwe maitiro zvakanyanya nekuti inzira yewelding ine kupisa kwakadzikira, kuderera kwekudzikira, uye kushomeka kwecarbide. Izvi zvese zvinogonesa kugona kuwana yakanyanya kutetepa hardfacing overlays.

Cladding inzira yeWeld overlay process inoburitsa hutsva hutsva hunogona kushandiswa nemhando hombe yezvekufukidza zvinhu nenzira dzakasiyana senge hupfu, waya, kana cored waya. Uyezve, maitiro echinyakare ekufukidza anogona kushandiswa sezvakanyorwa pamusoro. Kungofanana nelaser hardfacing, laser cladding ine mabhenefiti pamusoro pemamwe maitiro zvakanyanya nekuti inzira yewelding ine kupisa kwakadzikira uye kuderedzwa kwakadzika. Izvi zvese zvinogonesa kugona kuwana yakanyanya kutetepa yakafukidzwa.

Laser hardfacing uye cladding anoshandiswa munenge ese indasitiri musika ane maapplication akadai:

• Mafuta negasi

• Zvemotokari

• Midziyo yekuvaka

• Zvekurima

• Kuchera

• Mauto

• Kugadzira magetsi

• Kugadziriswa nekuvandudzwa kwezvishandiso, mabladhi eturbine, neinjini

Laser hardfacing uye laser cladding zvese zvinopa zvakanakira kudiki kukanganiswa kwemafuta, kugadzirwa kwakanyanya, uye mutengo-kushanda.

Lasers In Hardfacing uye Cladding Maitiro

Kushandisa lasers sesosi yekupisa mukuomarara uye kupfekedza kunopa huchokwadi uye hushoma huwandu hwemakemikari dilution kuti weld zvinhu zviviri. Inopa nzira inodhura yekushandisa isingadhure substrate zvinhu nekuisa weld overlay, iyo inopa ngura, oxidation, kupfeka, uye tembiricha kuramba. Iyo yakanyanya kugadzirwa mwero iyo zvigadzirwa zvinogona kupedzwa zvakasanganiswa nemutengo wezvinhu zvakanakira kuita laser cladding uye hardfacing sarudzo yakakurumbira kune akawanda maindasitiri.