Chii chinonzi hardfacing?

Chii chinonzi hardfacing

Hardfacing ndiko kuiswa kwejira gobvu rezvinhu zvakaoma, zvisingapfekere pachinhu chakasakara kana chitsva chinopfekwa.ne welding, kupfapfaidza nemafuta, kana maitiro akafanana. Thermal spraying, spray-fuse uye welding maitiro anowanzo shandiswa kuisa iyo yakaoma-yakatarisana layer. Zvinowanzoshandiswa zvinhu zvinosanganisira cobalt-based alloys (senge tungsten carbide), nickel-based alloys,chromium carbidealloys, etc. Hardfacing dzimwe nguva inoteverwa nekupisa kutsika kugadziridza chikamu kana kuwedzera ruvara kana ruzivo rwekuraira kune chikamu. Mafoiri kana mafirimu anogona kushandiswa kutaridzika kwesimbi kana kumwe kudzivirira

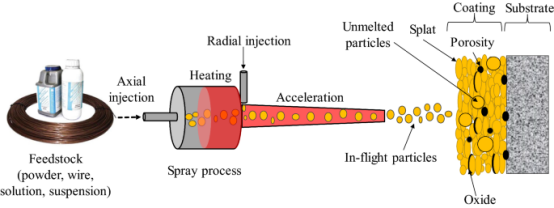

Thermal spraying inosarudzwa kune zvikumbiro zvinoda kushoma kwekupisa kwekukanganisa kwechikamu uye yakanaka maitiro ekutonga. Zvakajairwa zvekuomesa zvinhu zvakaiswa nekupfapfaidza zvinopisa zvinosanganisira macermets akadai seWC-Co uye alumina-based ceramics. Aya machira anoiswa kune ukobvu hunosvika 0.3mm.

Kupfapfaidza-fuse machira anonziwo seanozvifambisa pamusoro pemachira, anotanga kuiswa kune chikamu chepamusoro uchishandisa murazvo wekupfapfaidza maitiro uye wozosanganiswa uchishandisa oxyacetylene torch kana RF induction coil. Iyo yakasanganiswa coating inonyorovesa iyo substrate pamusoro kuti ibudise iyo yakasungwa nesimbi kune substrate uye isina porosity. Kune marudzi akasiyana-siyana alloy anoshandiswa nespray-fuse process, iyo inonyanya kukosha inobva paNi-Cr-B-Si-C alloy system. Zvichienderana nekuumbwa vanonyungudika muhupamhi hwe980 kusvika 1200°C.

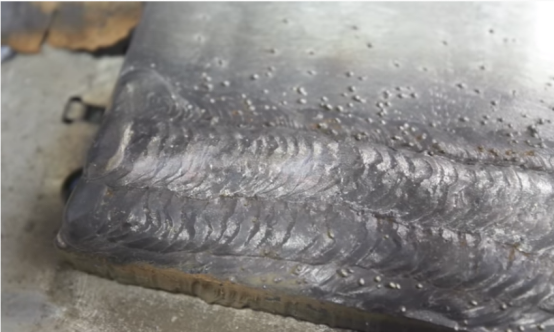

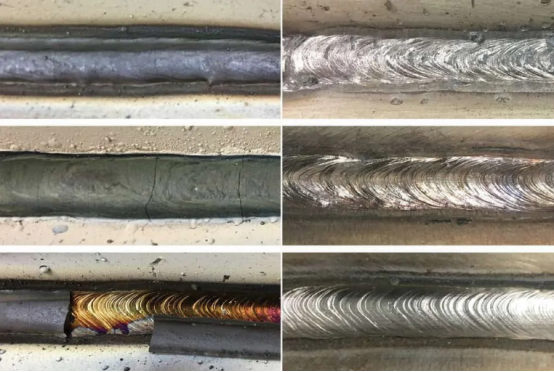

Weld yakaoma yakatarisana inoshandiswa kuisa yakakora kwazvo (1 kusvika 10mm) mitsetse yakakora yezvinhu isingapfeki uye yakasimba bond simba. Yakasiyana-siyana welding matekiniki anogona kushandiswa, kusanganisira simbi-inert gasi (MIG), tungsten inertgasi (TIG), plasma inotamiswa arc (PTA), yakadzika arc (SAW), uye manual metal arc (MMA). Rudzi rwakafara kwazvo rwezvokupfeka runogona kuiswa. Zvinosanganisira cobalt-based alloys (tungsten carbide nezvimwe.), martensitic uye high-speed steels, nickel alloys uye WC-Co cemented carbides. Mushure mekuiswa nechero ipi yeapamusoro welding maitiro, zvinowanzodiwa kupedzisa chikamu chepamusoro.

Hardfacing inogona kuiswa nenzira dzakasiyana dzewelding:

·Shielded metal arc welding

·Gasi simbi arc welding, kusanganisira ese ari maviri gasi-akadzivirirwa uye akavhurika arc welding

·Oxyfuel welding

·Kunyura mumvuraarc welding

·Electroslag welding

·Plasma yakatamiswa arc welding, inonziwo poda plasma welding

·Thermal spraying

·Cold polymer compounds

·Laser cladding

·Hardpoint