Liphello tsa Chamfer ho PDC Cutters

Liphello tsa Chamfer ho PDC Cutters

Li-cutters tsa PDC (Polycrystalline diamond compact) li bapala karolo ea bohlokoa ts'ebetsong ea likotoana tsa PDC ho cheka oli le khase. Ho bohlokoa haholo ho ithuta mokhoa oa ho pshatla mafika bakeng sa li-bits tsa PDC ho sebetsana le libopeho tse phephetsang, haholo-holo ha liliba li fetoha nako e telele le tse rarahaneng.

Har'a lintlha tsohle tse susumetsang ts'ebetso ea ho itšeha, chamfer e bonolo ho hlokomolohuoa lithutong tsa theory le tsa liteko.

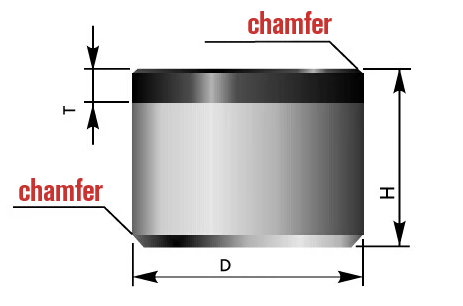

Chamfer ke moeli oa nakoana pakeng tsa lifahleho tse peli tsa ntho. Li-cutters tsa PDC hangata li na le chamfer ka bobeli ka tlase le lera la daemane.

Bohareng ba lilemo tsa bo-1990, theknoloji ea chamfering e ile ea qala ho sebelisoa haholo ho li-cutters tsa PDC, 'me theknoloji ea multi-chamfering e ile ea amoheloa ka mokhoa oa patent ka 1995. Haeba mokhoa oa chamfering o sebelisoa ka nepo, ho hanyetsa ho robeha ha sehaho nakong ea ho cheka ho ka khoneha. e ka ntlafatsoa ka 100%. Khampani ea Baker Hughes e atlehile ho sebelisa theknoloji ea chamfer habeli ka meno lilemong tsa morao tjena.

PDC cutter ea habeli-chamfer ke theknoloji e ncha e kopanyang chamfer ea mantlha e nang le moeli oa bobeli, e nolofalletsang ho chekoa litšoantšo tse kholo ntle le ho senya sekhahla sa ho kenella (ROP). Ho tloha ka 2013, ho se ho entsoe lithunya tse fetang 1,500 tse nang le li-bits tse sebelisang theknoloji ea chamfer habeli Oklahoma. Boemo bo sa hlakang bo ile ba ntlafala haholo, bo bakileng ho fokotsoa ha melumo, ho ntšoa ha core out, le tšenyo e 'ngoe e mpe.

Li-cutters tsa Chamfering polycrystalline diamond compact (PDC) li na le phello e ntle ho tšoarellang nako e telele le bophelo bo bolelele ka kakaretso. Mohopolo ona ha o so fetohe ho feta lilemo tse mashome ho tloha ha li-cutters tsa PDC li hlahisoa. Lipatlisiso tse ngata li entsoe ka phetoho e le 'ngoe ho bophahamo ba chamfer kapa angle ea chamfer kapa ka li-geometri tse kopaneng.

Ho ile ha fumanoa hore angle e nyane e bolela ROP e phahameng empa e na le tšekamelo ea ho senya le ho senya ho feta angle e kholo. A angle e kholo e bolela li-cutters tse tšoarellang ho feta empa ROP e tlase. Boleng ba angle bo tlameha ho ntlafatsoa ho ea ka mefuta ea sebopeho se tloaelehileng se lokelang ho chekoa.

Bakeng sa moreki, thekenoloji e ntlafetseng ea li-cutter e entse hore ho bolokoe litšenyehelo tse ngata le ho itšepa haholoanyane bophelong ba lisebelisoa, ho etsa hore ho be le mamello le ho tšoarella nako e telele. Qetellong, thekenoloji e ncha ea ho cheka e thusa ho fokotsa litšenyehelo tsa ho cheka le ho bula meeli e mengata ea ho cheka eo pele e neng e se na phaello.

Rea u amohela ho re fumana ka li-cutters tsa PDC, li-cutters tsa PDC tse peli li teng.

Haeba u thahasella lihlahisoa tsa tungsten carbide 'me u batla boitsebiso bo eketsehileng le lintlha tse ling, u ka RE THUTA ka mohala kapa ka poso ka ho le letšehali, kapa U RE THUSE MAIL botlaaseng ba leqephe.