Theknoloji ea Welding ea PDC

Theknoloji ea Welding ea PDC

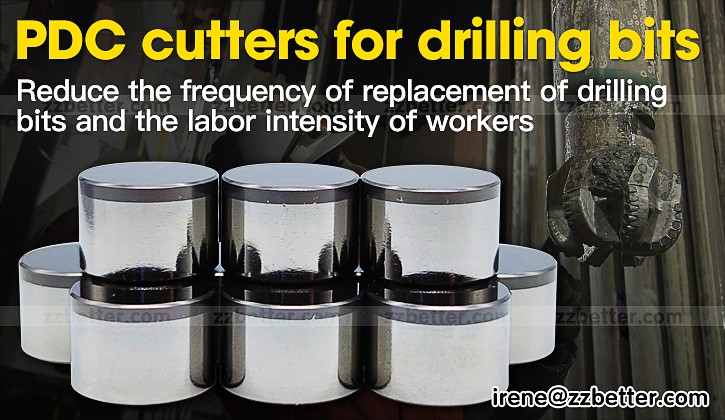

Li-cutters tsa PDC li na le boima bo phahameng, khanyetso e phahameng ea daemane, le ho tiea ho matla ha carbide e entsoeng ka samente. E 'nile ea sebelisoa haholo ho cheka jeoloji, ho cheka oli le khase, le lisebelisoa tsa ho seha. Mocheso oa ho hloleha ha lera la daemane la polycrystalline ke 700 ° C, kahoo mocheso oa lera la daemane o tlameha ho laoloa ka tlase ho 700 ° C nakong ea ts'ebetso ea welding. Mokhoa oa ho futhumatsa o phetha karolo ea bohlokoa ts'ebetsong ea brazing ea PDC. Ho latela mokhoa oa ho futhumatsa, mokhoa oa brazing o ka aroloa ka ho chesoa ha lelakabe, brazing ea vacuum, vacuum diffusion bonding, high-frequency induction brazing, laser beam welding, joalo-joalo.

PDC e chesa lelakabe

Flame brazing ke mokhoa oa ho cheselletsa o sebelisang lelakabe le hlahisoang ke khase bakeng sa ho futhumatsa. Ntlha ea pele, sebelisa lelakabe ho futhumatsa 'mele oa tšepe, ebe u tsamaisa lelakabe ho PDC ha phallo e qala ho qhibiliha. Mokhoa o ka sehloohong oa ho chesoa ha lelakabe o kenyelletsa phekolo ea pele ho weld, ho futhumatsa, ho boloka mocheso, ho pholisa, phekolo ea post-weld, joalo-joalo.

PDC vacuum brazing

Vacuum brazing ke mokhoa oa ho tjheseletsa o futhumatsang sesebediswa sa mosebetsi sebakeng sa vacuum sepakapakeng ntle le khase e oxidizing. Vacuum brazing ke ho sebelisa mocheso oa ho hanyetsa oa workpiece e le mohloli oa mocheso ha nako e ntse e ea sebakeng sa heno e pholisa lera la taemane la polycrystalline ho kenya ts'ebetsong ea mocheso o phahameng oa mocheso. Ho sebelisa metsi a pholileng a tsoelang pele nakong ea ts'ebetso ea brazing ho netefatsa hore mocheso oa lera la daemane o laoloa ka tlase ho 700 ° C; tekanyo ea vacuum sebakeng se batang sa brazing e hlokeha ho ba tlase ho 6. 65 × 10-3 Pa, 'me tekanyo ea vacuum sebakeng se chesang e ka tlaase ho 1. 33 × 10-2 Pa. Ka mor'a ho tjheseletsa, beha workpiece. ka incubator bakeng sa ho boloka mocheso ho felisa khatello ea mocheso e hlahisoang nakong ea ts'ebetso ea brazing. Matla a ho kuta a li-vacuum brazing joints a batla a tsitsitse, matla a kopane a phahame, 'me matla a ho kuta a ka fihla ho 451.9 MPa.

PDC vacuum diffusion bonding

Vacuum diffusion bonding ke ho etsa hore bokaholimo ba lisebelisoa tse hloekileng tsa ho sebetsa ka har'a vacuum haufi le tse ling ka mocheso o phahameng le khatello e phahameng, liathomo li arohane ka sebaka se batlang se le nyane, ka hona li kopanya likarolo tse peli hammoho.

Karolo ea bohlokoa ka ho fetisisa ea ho kopanya li-diffusion:

1. motsoako oa metsi o entsoeng ka har'a seame sa brazing nakong ea mokhoa oa ho futhumatsa oa brazing

2. motsoako oa metsi o bolokoa nako e telele mocheso o phahameng ho feta mocheso o tiileng oa tšepe ea brazing filler e le hore e tiisetsoe ka isothermally ho etsa seam sa brazing.

Mokhoa ona o sebetsa haholo bakeng sa karoloana ea PDC e samente ea carbide le daemane, tse nang le li-coefficients tse fapaneng tsa katoloso. Ts'ebetso ea ho kopanya vacuum diffusion e ka hlola bothata boo PDC e leng bonolo ho oela ka lebaka la ho theoha ho hoholo ha matla a tšepe ea brazing filler. (nakong ea ho cheka, mocheso oa eketseha, 'me matla a tšepe ea tšepe a tla theoha haholo.)

Haeba o khahlehela li-cutters tsa PDC 'me u batla lintlha le lintlha tse ling, u ka ITHUTA KA HO THUSA KA mohala kapa ka poso ka letsohong le letšehali, kapa U RE THUSE MAIL botlaaseng ba leqephe.