Ulwazi oluSisiseko lwePDC Cutter

Ulwazi oluSisiseko lwePDC Cutter

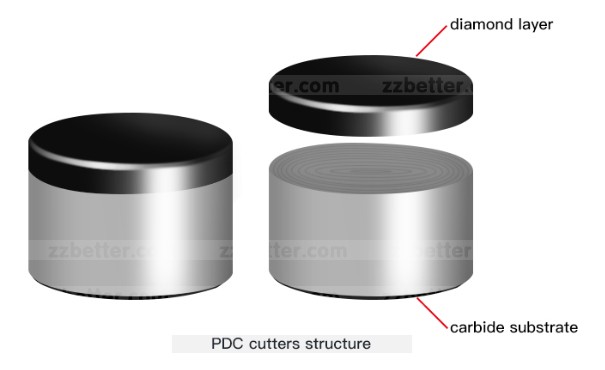

I-PDC imele i-polycrystalline diamond compact. Ngokwenyani, i-PDC bit isebenzisa iwafa yedayimani engqukuva ebotshelelwe kwisiseko se-carbide njengendlela yokuqala yokusika. Idayimani isekelwe kwi-polycrystalline kwaye ineenzuzo zokuhlala ixesha elide kunye nokuzilola.

Idayimani yokwenziwa ixhaphake kangangamaxesha ali-150 ngaphezulu kwe-abrasion kune-carbide. Iphuhliswe yi-GE, ezi dayimani zixhaphakile zibonelelwa njengenxalenye yokwenziwa yokwenziwa ngobuninzi eyenziwe phantsi kobushushu obuphezulu kunye noxinzelelo lokwenza iiwafa zedayimani ezichanekileyo.

Inkqubo yokukhutshwa kweekhemikhali isusa i-cobalt catalyst kwi-microstructure yePDC. I-PDC yedayimani leaching linyathelo elibalulekileyo lenkqubo elonyusa ngokumangalisayo ixesha elide kunye nokusebenza kwebit.

Iiwafers ke zidityaniswa neziseko zekhabhoni. Esi siseko se-carbide sisebenza imisebenzi emibini. Okokuqala, zibonelela ngendlela eyomeleleyo yokuxhasa iiwafa zedayimani. Okwesibini, ibonelela ngendlela yokuncamathisela idayimani kumzimba omncinci kuba awukwazi ukuthengisa okanye ukuwelda iidayimani. Injongo kukubonelela zombini i-cutter ehlala ixesha elide ngelixa ukhulisa amazinga okungena.

Icandelo ledayimane kwi-carbide substrate ye-PDC bit ibizwa ngokuba ngumsiki. Ziza kubukhulu obuthathu obuyi-13mm, 16mm, kunye ne-19 mm. bit PDC ikakhulu isebenzisa 1308 cutter.

Olunye uphawu olubalulekileyo lwabasiki bedayimani yi-chamfer, eyona i-angle ye-edge edge yedayimane. Le engile ibaluleke kakhulu kuyilo lwebit kunye nokusebenza. Akukho zicheri (zero degrees) zisika azisetyenziswanga kwaye ziya kusetyenziswa kuphela kumhlaba othambileyo njengoko ziqhele ukutshiphuza. I-chamfer ye-12-degree yindlela yokungena ngokukhawuleza. Basethanda ukutshiphuza ngokulula. I-Zzbetter inokwenza i-chamfer ngokweemfuno zomthengi.

Isiseko se-carbide sibaluleke kakhulu ekusebenzeni komsiki. Abasiki bezinga eliphezulu baboshwe kwiziseko ezifanelekileyo kunye neegridi ezichanekileyo. Iziseko ezikumgangatho ophantsi ziya kwenza indibano ye-cutter ekumgangatho ophantsi.

Isiseko se-carbide sibaluleke kakhulu ekusebenzeni komsiki. Abasiki bezinga eliphezulu baboshwe kwiziseko ezifanelekileyo kunye neegridi ezichanekileyo, ngelixa iziseko ezisemgangathweni ziya kwenza indibano ye-cutter esemgangathweni.

Umgangatho ophezulu wePDC ugcinwe ngokufanelekileyo kwaye usetyenziswa xa usetyenziswa kwiindawo ezifanelekileyo ezifana nelitye lesanti libhalwe ukuba lihlala ixesha elide kakhulu.

Ukuba unomdla kwiimveliso ze-tungsten carbide kwaye ufuna ulwazi oluthe kratya kunye neenkcukacha, ungaQHAGAMSHELANA NATHI ngefowuni okanye ngeposi ekhohlo, okanye SITHUMELE MAIL emazantsi ephepha.