Yimalini oyaziyo malunga nePDC Cutter?

Wazi kangakanani malunga nePDC cutter?

Malunga nePDC (iPolycrystalline Diamond Compact) Umsiki

I-PDC (i-Polycrystalline Diamond Compact) Umsiki luhlobo lwe-superhardizinto ezidibanisa idayimani ye-polycrystalline kunye ne-tungsten carbide substrate kubushushu obuphezulu kunye noxinzelelo.

Ukuveliswa kwePDC cutter yaqhubela phambilii-fixed-cutter bitphambili kushishino lokomba, kwaye ingcamango ngoko nangoko yaduma. Ukususela kwiukuchebaisenzo se-PDC cutters sisebenza ngakumbi kunesenzo sokutyumza iqhosha okanye i-toothed bit, i-cutters fixed- kancincizifunwa kakhulu.

Ngo-1982, i-PDC drill bits ibalelwa kwi-2% kuphela yeenyawo zizonke ezombiweyo. Ngo-2010, i-65% yendawo yonke eyombiweyo yaveliswa yiPDC.

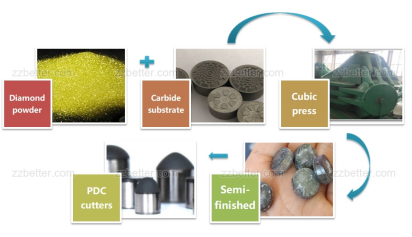

Zenziwa njani ii-PDC Cutters?

I-PDC Cutters zenziwe nge-tungsten carbide substrate kunye ne-synthetic diamond grit. Yenziwe ngokusebenzisa indibaniselwano yobushushu obuphezulu kunye noxinzelelo oluphezulu kunye ne-catalyst ye-cobalt alloy yokunceda i-diamond yebhondi kunye ne-carbide ngexesha lenkqubo ye-sintering. Ngethuba lenkqubo yokupholisa, i-tungsten carbide iyancipha ngesantya se-2.5 ngokukhawuleza kunedayimane, edibanisa iDayimane kunye ne-Tungsten Carbide kunye kwaye emva koko yenza i-PDC Cutter.

Iimpawu kunye nezicelo

Kuba ii-PDC Cutters ziquka igrit yedayimane kunye ne-tungsten carbide substrate, idibanisa izibonelelo zazo zombini idayimani kunye ne-tungsten carbide.:

1. HInganyangeki kwi-abrasion

2. HUkumelana nefuthe

3. Hisitali se-thermal

Ngoku ii-PDC Cutters zisetyenziswa ngokubanzi kwindawo yokomba i-oyile, irhasi kunye nophononongo lwejoloji, ukumbiwa kwamalahle, kunye nezinye izinto ezininzi zokomba nokungqusha, izixhobo zokusebenza njenge-PDC Drill Bits, ezifana ne-Steel PDC Drill Bits & Matrix PDC Drill Bits yokomba ioli kunye I-Tri-cone PDC Drill Bits kwimigodi yamalahle.

Ukulinganiselwa

Umonakalo wempembelelo, umonakalo wobushushu, kunye nokunxitywa kwe-abrasive konke kunqanda ukusebenza kwesuntswana le-drill kwaye kungenzeka nakweyona ndlela ithambileyo yokwakheka komhlaba. Nangona kunjalo, olona qulunqo lunzima lwe-PDC bit ukugrunjwa luyingozi kakhulu.

Enkulu VS umsiki omncinci

Njengomthetho jikelele, abasiki abakhulu (19mm ukuya kwi-25mm) banobudlova kunabasiki abancinci. Nangona kunjalo, banokunyusa ukuguquguquka kwetorque. Ukongeza, ukuba i-BHA ayenzelwanga ukuphatha ubundlongo-ndlongo obuninzi, ukungazinzi kunokubangela.

Abasiki abancinci (8mm, 10mm, 13mm, kunye ne-16mm) babonakaliswe ukugrumba kwi-ROP ephezulu kunabasiki abakhulu kwizicelo ezithile. Esinye sezicelo ezinjalo yi-limestone.

Kwakhona, amasuntswana ayilwe ngabasiki abancinci kodwa uninzi lwazo lunokumelana nempembelelo ephezulu iyalayisha.

Ukongeza, abasiki abancinci bavelisa iinqumle ezincinci ngelixa abasiki abakhulu bevelisa ukusika okukhulu. Ukusikwa okukhulu kunokubangela iingxaki zokucocwa komngxuma ukuba ulwelo lokugrumba alukwazi ukuthwala ukusika kwi-annulus.

imilo yomsiki

Eyona milo ixhaphakileyo yePDC sisilinda, ngokuyinxenye ngenxa yokuba abasiki be-cylindrical banokucwangciswa ngokulula ngaphakathi komqobo weprofayile enikiweyo ukuphumeza ingxinano enkulu yomsiki. Oomatshini bokukhupha i-Electron banokusika ngokuchanekileyo kwaye bamise iitafile zedayimani zePDC. Ujongano olungacwangciswanga phakathi kwetafile yedayimani kunye ne-substrate inciphisa uxinzelelo olushiyekileyo. Ezi mpawu ziphucula ukuxhathisa kwi-chipling, spalling, kunye ne-diamond table delamination. Olunye uyilo lojongano lwandisa ukuxhathisa impembelelo ngokunciphisa amanqanaba oxinzelelo olushiyekileyo.