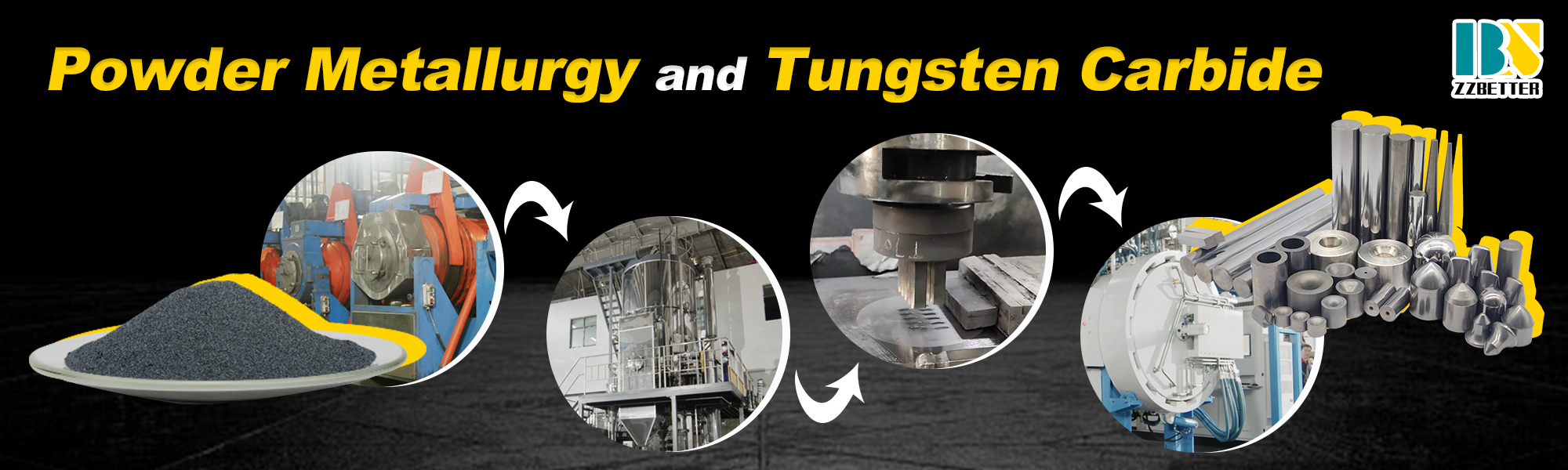

I-Powder Metallurgy ne-Tungsten Carbide

I-Powder Metallurgy ne-Tungsten Carbide

Embonini yesimanje, imikhiqizo ye-tungsten carbide yenziwa ikakhulukazi nge-powder metallurgy. Ungase ube nemibuzo eminingi mayelana ne-powder metallurgy ne-tungsten carbide. Iyini i-powder metallurgy? Iyini i-tungsten carbide? Futhi Yenziwa kanjani i-tungsten carbide nge-powder metallurgy? Kulesi sihloko eside, uzothola impendulo.

Okuqukethwe okuyinhloko kwalesi sihloko kungokulandelayo:

1.I-powder metallurgy

1.1Isingeniso esifushane se-powder metallurgy

1.2 Umlando we-powder metallurgy

1.3Impahla ezokwenziwa ngempushana yensimbi

1.4Inqubo yokukhiqiza nge-powder metallurgy

2.I-tungsten carbide

2.1 Ukwethulwa kafushane kwe-tungsten carbide

2.2 Izizathu zokusebenzisa i-powder metallurgy

2.3 Inqubo yokukhiqiza ye-tungsten carbide

3.Summary

1.I-powder metallurgy

1.1Isingeniso esifushane se-powder metallurgy

I-powder metallurgy iyinqubo yokukhiqiza yokwenza izinto noma izingxenye ngokuhlanganisa impushana ibe yisimo esithile bese uyicwilisa ngaphansi kwezinga lokushisa elingaphansi kwamaphuzu ancibilikayo. Le ndlela ayibonwa njengendlela ephakeme kakhulu yokukhiqiza izingxenye zekhwalithi ephezulu kuze kube yikota yekhulu leminyaka edlule. Inqubo ye-tungsten carbide ngokuyinhloko ihlanganisa izingxenye ezimbili: enye ihlanganisa i-powder ku-die, kanti enye ishisa i-compact endaweni evikelekile. Le ndlela ingasetshenziswa ukukhiqiza izingxenye eziningi ze-structural powder metallurgy, i-self-lubricating bear, namathuluzi okusika. Phakathi nale nqubo, i-powder metallurgy ingasiza ukulahlekelwa kwezinto ezibonakalayo futhi inciphise izindleko zemikhiqizo yokugcina. Ngokuvamile, i-powder metallurgy ifanele ukukhiqiza leyo mikhiqizo ezobiza kakhulu ngenye inqubo noma ehlukile futhi engenziwa kuphela nge-powder metallurgy. Enye yezinzuzo ezinkulu ze-powder metallurgy ukuthi inqubo ye-powder metallurgy iguquguquka ngokwanele ukuvumela ukuthungwa kwezimpawu ezibonakalayo zomkhiqizo ukuze zivumelane nempahla yakho ethile kanye nezidingo zokusebenza. Lezi zici zomzimba zihlanganisa isakhiwo esiyinkimbinkimbi nesimo, i-porosity, ukusebenza, ukusebenza ekucindezelekeni, ukumuncwa kokudlidliza, ukunemba okukhulu, ukuqedwa okuhle kwendawo, uchungechunge olukhulu lwezicucu ezinokubekezelelana okuncane, kanye nezakhiwo ezikhethekile ezinjengobulukhuni nokumelana nokugqoka.

1.2 Umlando we-powder metallurgy

Umlando we-powder metallurgy uqala nge-metal powder. Eminye imikhiqizo yempushana yatholakala emathuneni aseGibhithe ekhulwini lesithathu BC, futhi izinsimbi ezingenayo insimbi nensimbi zatholakala maphakathi neMpumalanga, zabe sezisakazekela eYurophu nase-Asia. Izisekelo zesayensi ze-powder metallurgy zatholwa usosayensi waseRussia uMikhail Lomonosov ngekhulu le-16. Ungowokuqala ukutadisha inqubo yokuguqula izinsimbi ezihlukahlukene, njengomthofu, zibe yizimo eziyimpuphu.

Nokho, ngo-1827, omunye usosayensi waseRussia uPeter G. Sobolevsky wethula indlela entsha yokwenza ubucwebe nezinye izinto ngezimpushana. Ekuqaleni kwekhulu lamashumi amabili, izwe lashintsha. Kusetshenziswa ubuchwepheshe be-powder metallurgy, futhi ngokuthuthukiswa kwe-electronics, inzalo yanda. Ngemuva kwekhulu lama-21, imikhiqizo ekhiqizwa yi-powder metallurgy yanda kakhulu.

1.3 Izinto ezizokwenziwa nge-powder metallurgy

Njengoba sesishilo ngaphambili, i-powder metallurgy ilungele ukukhiqiza leyo mikhiqizo ezobiza kakhulu ngenye inqubo noma ehlukile futhi ingenziwa kuphela nge-powder metallurgy. Kule ngxenye, sizokhuluma ngalezi zinto ngokuningiliziwe.

A.Materials ezibiza kakhulu ngenye inqubo

Izingxenye zesakhiwo nezinto ezinama-porous yizinto ezibiza kakhulu ngezinye izindlela. Izingxenye zesakhiwo zihlanganisa ezinye izinsimbi, njengethusi, ithusi, ithusi, i-aluminium, njalonjalo. Angenziwa ngezinye izindlela. Kodwa-ke, abantu bathanda ukwenza i-powder metallurgy ngenxa yezindleko eziphansi. Izinto ezinama-porous ezifana nokugcina uwoyelaama-bearings ngokuvamile enziwa yi-powder metallurgy. Ngale ndlela, ukusebenzisa i-powder metallurgy kunganciphisa izindleko zokuqala.

B. Izinto eziyingqayizivele ezingenziwa kuphela nge-powder metallurgy

Kunezinhlobo ezimbili zezinto eziyingqayizivele ezingakwazi ukukhiqizwa ngezinye izindlela. Ziyizinsimbi eziphikisayo nezinto eziyinhlanganisela.

Izinsimbi eziphikisayo zinezindawo eziphakeme zokuncibilika futhi kunzima ukuzikhiqiza ngokuncibilika nokujikijela. Eziningi zalezi zinsimbi nazo ziyabola. I-Tungsten, i-molybdenum, i-niobium, i-tantalum, ne-rhenium ingezalezi zinsimbi.

Ngokuqondene nezinto ezihlanganisiwe, kunezinto ezihlukahlukene, ezifana nezinto zokuxhumana zikagesi, izinsimbi eziqinile, izinto zokungqubuzana, amathuluzi okusika idayimane, imikhiqizo eminingi eyenziwe, inhlanganisela ethambile kazibuthe, njalonjalo. Lezi zinhlanganisela zezinsimbi ezimbili noma ngaphezulu azincibiliki, kanti ezinye izinsimbi zinamaphuzu aphezulu ancibilika.

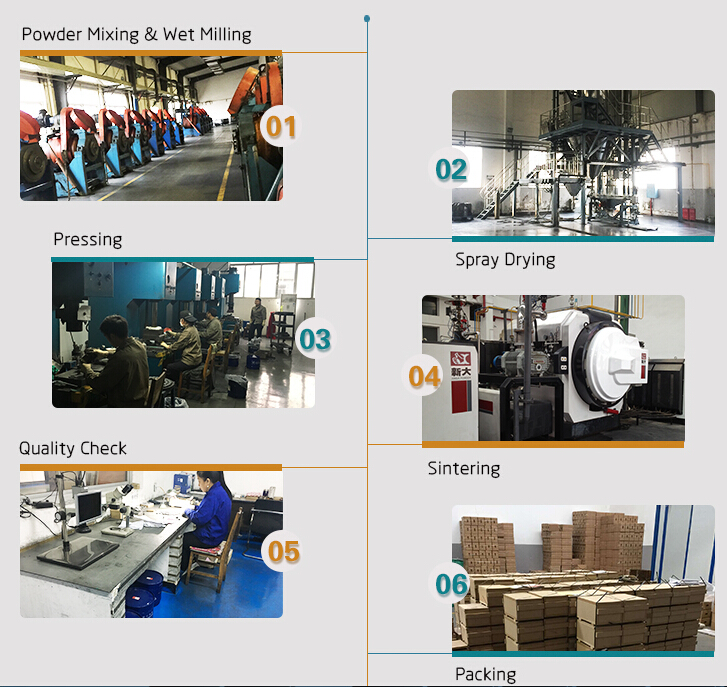

1.4Inqubo yokukhiqiza nge-powder metallurgy

Inqubo eyinhloko yokukhiqiza ku-powder metallurgy ukuxuba, ukuhlanganisa, nokucwilisa.

1.4.1 Ingxube

Hlanganisa impushana yensimbi noma izimpushana. Le nqubo yenziwa emshinini wokugaya ibhola one-binder metal.

1.4.2 Ihlangene

Layisha ingxube ku-die noma isikhunta bese usebenzisa ingcindezi. Kule nqubo, ama-compact abizwa nge-green tungsten carbide, okusho ukuthi i-tungsten carbide engafakiwe.

1.4.3 Umshicileli

Shisisa i-tungsten carbide eluhlaza endaweni evikelayo ezingeni lokushisa elingaphansi kwendawo yokuncibilika yezingxenye eziyinhloko ukuze izinhlayiya zempushana zihlangane futhi zinikeze amandla anele entweni ukuze isetshenziswe. Lokhu kubizwa nge-sintering.

2.I-tungsten carbide

2.1 Ukwethulwa kafushane kwe-tungsten carbide

I-Tungsten carbide, ebizwa nangokuthi i-tungsten alloy, i-hard alloy, insimbi eqinile, noma i-carbide enosimende, ingenye yezinto zamathuluzi anzima kakhulu emhlabeni, kuphela ngemva kwedayimane. Njengenhlanganisela ye-tungsten ne-carbon, i-tungsten carbide izuza ifa lezinto ezimbili zokusetshenziswa. Inezici eziningi ezinhle njengokuqina okuphezulu, amandla amahle, ukumelana nokugqoka, ukumelana nomthelela, ukumelana nokushaqeka, ukuqina, njalonjalo. Amabanga nawo angaba yingxenye yokuthonya ukusebenza kwe-tungsten carbide ngokwayo. Kukhona uchungechunge lwama-grads amaningi, afana ne-YG, YW, YK, njalonjalo. Lolu chungechunge lwebanga luhlukile kumpushana wokuhlanganisa ongezwe ku-tungsten carbide. I-YG series tungsten carbide ikhetha i-cobalt njenge-binder yayo, kuyilapho i-YK series tungsten carbide isebenzisa i-nickel njengesibophezelo sayo.

Njengoba kunezinzuzo eziningi kangaka ezigxile kulolu hlobo lwezinto zamathuluzi, i-tungsten carbide inezinhlelo zokusebenza ezibanzi. I-Tungsten carbide ingenziwa ngezinhlobo eziningi zemikhiqizo, okuhlanganisa izinkinobho ze-tungsten carbide, izinduku ze-tungsten carbide, amapuleti e-tungsten carbide, izigayo zokuphela kwe-tungsten carbide, ama-tungsten carbide burrs, ama-tungsten carbide blades, izikhonkwane ze-tungsten carbide punch, ama-tungsten carbide welding, kanye ne-composite ku. Zingasetshenziswa kabanzi njengengxenye yokubhoboza umhubhe, ukumba, nokumbiwa kwezimayini. Futhi angasetshenziswa njengethuluzi lokusika ukwenza ukusika, ukugaya, ukujika, ukugoba, nokunye. Ngaphandle kwesicelo sezimboni, i-tungsten carbide ingasetshenziswa ekuphileni kwansuku zonke, njengebhola elincane ku-nib yepeni yejeli.

2.2 Izizathu zokusebenzisa i-powder metallurgy

I-Tungsten carbide iyinsimbi ephikisayo, ngakho-ke kunzima ukuyicubungula ngezindlela ezijwayelekile zokukhiqiza. I-Tungsten carbide iyinto engenziwa kuphela nge-powder metallurgy. Ngaphandle kwe-tungsten carbide, imikhiqizo ye-tungsten carbide iqukethe nezinye izinsimbi, njenge-cobalt, i-nickel, i-titanium, noma i-tantalum. Zixutshwe, zicindezelwe yisikhunta, bese zifakwa emazingeni okushisa aphezulu. I-Tungsten carbide inendawo ephakeme yokuncibilika, futhi kufanele ifakwe emanzini ekushiseni okuphezulu okungu-2000鈩?

2.3 Inqubo yokukhiqiza ye-tungsten carbide

Embonini, sisebenzisa i-powder metallurgy ukwenza imikhiqizo ye-tungsten carbide.Inqubo eyinhloko ye-powder metallurgy ukuxuba izimpushana, izimpushana ezihlangene, nama-compact compact aluhlaza. Uma sicabangela izakhiwo ezikhethekile ze-tungsten carbide esikhulume ngazo ku-2.1 izingeniso ezimfishane ze-tungsten carbide, inqubo yokukhiqiza i-tungsten carbide iyinkimbinkimbi kakhulu. Imininingwane imi kanje:

2.3.1 Ukuxuba

Ngesikhathi sokuxuba, izisebenzi zizoxuba i-tungsten carbide powder yekhwalithi ephezulu ne-binder powder ngokuyinhloko i-cobalt noma i-nickel powder, ngesilinganiso esithile. Ingxenye inqunywa izinga amakhasimende alidingayo. Isibonelo, kukhona u-8% we-cobalt powder ku-YG8 tungsten carbide. Izimpushana zokuhlanganisa ezihlukene zinezinzuzo ezihlukene. Njengoba evame kakhulu, i-cobalt iyakwazi ukumanzisa izinhlayiya ze-tungsten carbide futhi ibophe ngokuqinile kakhulu. Kodwa-ke, intengo ye-cobalt ikhuphuka, futhi insimbi ye-cobalt iya ngokuya ingavamile. Ezinye izinsimbi ezimbili ezibophayo ziyi-nickel ne-ayoni. Imikhiqizo ye-tungsten carbide enempushana yensimbi njengesibophezelo inamandla aphansi emishini kunalawo anempushana ye-cobalt. Ngezinye izikhathi, izimboni zizosebenzisa i-nickel esikhundleni se-cobalt, kodwa izakhiwo zemikhiqizo ye-tungsten carbide-nickel zizoba ngaphansi kunemikhiqizo ye-tungsten carbide-cobalt.

2.3.2 Ukugaya okumanzi

Izingxube zifakwa emshinini wokugaya ibhola, lapho kukhona ama-tungsten carbide liners noma ama-stainless steel liners. Ngesikhathi sokugaya okumanzi, i-ethanol namanzi kwengezwa. Usayizi wokusanhlamvu wezinhlayiya ze-tungsten carbide uzothinta izakhiwo zemikhiqizo yokugcina. Ngokuvamile, i-tungsten carbide enosayizi omkhulu wokusanhlamvu izoba nobunzima obuphansi.

Ngemuva kokugaya okumanzi, ingxube ye-slurry izothululelwa esitsheni ngemva kokuhlunga, okuyisilinganiso esibalulekile sokuvimbela i-tungsten carbide ekungcoleni. I-slurry tungsten carbide igcinwa esitsheni ukuze ilinde izinyathelo ezilandelayo.

2.3.3 Isifutho esomile

Le nqubo iwukuhwamulisa amanzi ne-ethanol ku-tungsten carbide futhi komise ingxube ye-tungsten carbide powder embhoshongweni wokomisa isifutho. Amagesi ahloniphekile anezelwa embhoshongweni wesifutho. Ukuqinisekisa izinga le-tungsten carbide yokugcina, uketshezi oluku-tungsten carbide kufanele lome ngokuphelele.

2.3.4 Ukusefa

Ngemva kwesifutho esomile, izisebenzi zizosefa i-tungsten carbide powder ukuze zisuse izigaxa ze-oxidation ezingaba khona, ezizothinta ukuminyana nokucwiliswa kwe-tungsten carbide.

2.3.5 Ukuhlanganisa

Ngesikhathi sokuhlanganisa, isisebenzi sizosebenzisa imishini ukukhiqiza ama-tungsten carbide aluhlaza ahlangene ngobukhulu obuhlukahlukene kanye nokwakheka ngokusho kwemidwebo. Ngokuvamile, ama-compact aluhlaza acindezelwa yimishini ezenzakalelayo. Eminye imikhiqizo ihlukile. Isibonelo, izinduku ze-tungsten carbide zenziwe ngemishini yokukhipha noma imishini ye-isostatic yesikhwama esomile. Ubukhulu bezinto ezihlangene eziluhlaza bukhulu kunemikhiqizo yokugcina ye-tungsten carbide, njengoba ama-compacts azoshwabana ekushiseni. Ngesikhathi sokuhlanganisa, ezinye izinto zokwakha ezifana ne-wax kapharafini zizokwengezwa ukuze kutholwe ama-compact okulindelekile.

2.3.6 Ukucula

Kubonakala sengathi ukucwilisa amanzi kuyinqubo elula ngoba abasebenzi badinga kuphela ukubeka ama-compact aluhlaza esithandweni somlilo. Eqinisweni, ukucula kuyinkimbinkimbi, futhi kunezigaba ezine ngesikhathi sokucula. Ziwukususwa kwe-ejenti yokubumba kanye nesiteji sokushiswa kwangaphambili, isigaba esiqinile se-sintering, isigaba se-liquid sintering, nesiteji sokupholisa. Imikhiqizo ye-tungsten carbide incipha kakhulu phakathi nesigaba esiqinile se-sintering.

Ku-sintering, izinga lokushisa kufanele lenyuke kancane kancane, futhi izinga lokushisa lizofinyelela inani eliphakeme kakhulu esigabeni sesithathu, isigaba se-liquid sintering. Indawo ye-sintering kufanele ihlanzeke kakhulu. Imikhiqizo ye-tungsten carbide izoncipha kakhulu phakathi nale nqubo.

2.3.7 Ukuhlola Okokugcina

Ngaphambi kokuba abasebenzi bapakishe imikhiqizo ye-tungsten carbide futhi bayithumele kumakhasimende, zonke izingxenye zomkhiqizo we-tungsten carbide kufanele zihlolwe ngokucophelela. Imishini ehlukahlukene kuma-laboratoriesizosetshenziswa kule nqubo, njenge-Rockwell hardness tester, i-microscope ye-metallurgical, i-density tester, i-coercimeter, njalonjalo. Ikhwalithi yabo kanye nezakhiwo, njengokuqina, ukuminyana, isakhiwo sangaphakathi, inani le-cobalt, nezinye izakhiwo, kufanele zihlolwe futhi ziqinisekiswe.

3.Summary

Njengethuluzi elidumile nelisetshenziswa kabanzi, i-tungsten carbide inemakethe ebanzi embonini yokukhiqiza. Njengoba sikhulume ngenhla, i-tungsten carbide inezinga eliphezulu lokuncibilika. Futhi iyinhlanganisela ye-tungsten, i-carbon, nezinye izinsimbi, ngakho-ke i-tungsten carbide kunzima ukuyikhiqiza ngezinye izindlela zendabuko. I-powder metallurgy abesilisa indima ebalulekile ekwenzeni imikhiqizo ye-tungsten carbide. Nge-powder metallurgy, imikhiqizo ye-tungsten carbide ithola izakhiwo ezihlukahlukene ngemva kochungechunge lwenqubo yokukhiqiza. Lezi zakhiwo, njengokuqina, amandla, ukumelana nokugqoka, ukumelana nokugqwala, nokunye, kwenza i-tungsten carbide isetshenziswe kabanzi ezimayini, ukusika, ukwakhiwa, amandla, ukukhiqiza, ezempi, i-aerospace, njalonjalo.

I-ZZBETTER izinikele ekukhiqizeni imikhiqizo ye-tungsten carbide esezingeni lomhlaba nesezingeni eliphezulu. Imikhiqizo yethu idayiselwe amazwe amaningi nezindawo futhi yenza impumelelo enkulu emakethe yasekhaya. Senza imikhiqizo ehlukahlukene ye-tungsten carbide, okuhlanganisa izinduku ze-tungsten carbide, izinkinobho ze-tungsten carbide, i-tungsten carbide iyafa, ama-tungsten carbide blades, ama-tungsten carbide rotary burrs, njalonjalo. Imikhiqizo eyenziwe ngokwezifiso iyatholakala.

Uma unentshisekelo emikhiqizweni ye-tungsten carbide futhi ufuna ulwazi olwengeziwe nemininingwane, UNGATHI XHUMANA NATHI ngocingo noma ngemeyili kwesokunxele, noma SITHUMELE IMEYILI ezansi nekhasi.