Umehluko phakathi kwe-Tungsten Carbide kanye namathuluzi okusika we-HSS

Umehluko phakathi kwe-Tungsten Carbide ne-HSS Cutting Tools

Ngaphandle kwezinto ze-tungsten carbide, amathuluzi okusika nawo angakhiqizwa ngezinto zensimbi ezinesivinini esikhulu. Kodwa-ke, ngenxa yokwakheka kwamakhemikhali ahlukene kanye nezindlela zokukhiqiza ze-tungsten carbide nensimbi enesivinini esikhulu, ikhwalithi yamathuluzi okusika alungiselelwe nayo ihlukile.

1. Izakhiwo zamakhemikhali

Insimbi enesivinini esikhulu, eyaziwa nangokuthi insimbi yamathuluzi esivinini esikhulu noma insimbi yangaphambili, ngokuvamile ibizwa nge-HSS, izingxenye zamakhemikhali eziyinhloko yikhabhoni, i-silicon, i-manganese, i-phosphorus, isulfure, i-chromium, i-molybdenum, i-nickel, ne-tungsten. Inzuzo yokwengeza i-tungsten ne-chromium ensimbi yangaphambili ukuthuthukisa ukumelana nokuthambisa komkhiqizo lapho ushiswa, ngaleyo ndlela kwandise isivinini sawo sokusika.

I-Tungsten carbide, eyaziwa nangokuthi i-cemented carbide, i-alloy material esekelwe ezintweni eziyinkimbinkimbi zensimbi eziphikisayo kanye nensimbi njengesibophezelo. Izinhlanganisela ezinzima ezivamile yi-tungsten carbide, i-cobalt carbide, i-niobium carbide, i-titanium carbide, i-tantalum carbide, njll.

2. Izinto ezibonakalayo

Amandla aguquguqukayo ensimbi yesivinini esiphezulu-inhloso evamile ngu-3.0-3.4 GPa, ukuqina komthelela ngu-0.18-0.32 MJ/m2, futhi ukuqina kungu-62-65 HRC (lapho izinga lokushisa likhuphuka lifika ku-600 ° C lapho ukuqina kuzoba khona. 48.5 HRC). Kuyabonakala ukuthi insimbi enesivinini esikhulu inezici zamandla amahle, ukumelana nokugqokwa okuhle, ukumelana nokushisa okuphakathi, kanye ne-thermoplasticity empofu. Yiqiniso, izinkomba zokusebenza ezithile zensimbi enesivinini esikhulu zihlobene eduze nokwakheka kwamakhemikhali kanye nenani lempahla eluhlaza.

Amandla acindezelayo e-tungsten carbide evame ukusetshenziswa angama-6000 MPa kanti ubulukhuni bungama-69~81 HRC. Lapho izinga lokushisa likhuphukela ku-900 ~ 1000℃, ubulukhuni busengagcinwa cishe ku-60 HRC. Ngaphezu kwalokho, inamandla amahle, ukuqina, ukumelana nokugqoka, ukumelana nokushisa, nokumelana nokugqwala. Kodwa-ke, izinkomba ezithile zokusebenza ze-carbide enosimende zihlobene eduze nokwakheka kwamakhemikhali kanye nesilinganiso sempahla eluhlaza.

3. Inqubo yokukhiqiza

Inqubo yokukhiqiza insimbi enesivinini esikhulu ngokuvamile iwukuba: ukuncibilika kwesithando somlilo imvamisa, ukucwengisiswa ngaphandle kwesithando somlilo, i-vacuum degassing, i-electro slag remelting, umshini wokubumba osheshayo, isando sokubumba, ukuvala umshini wokunemba, ukugingqika okushisayo emikhiqizweni, isici sepuleti, nokudweba. emikhiqizweni.

Inqubo yokukhiqiza ye-tungsten carbide ngokuvamile iwukuhlanganisa, ukugaya okumanzi, ukomisa, ukucindezela, nokucwilisa.

4. Ukusetshenziswa

Insimbi enesivinini esikhulu isetshenziswa kakhulu ukwenza amathuluzi okusika (njengama-drill, ompompi, nama-saha blade) namathuluzi anembayo (njengamahobhu, ama-gear shaper, nama-broaches).

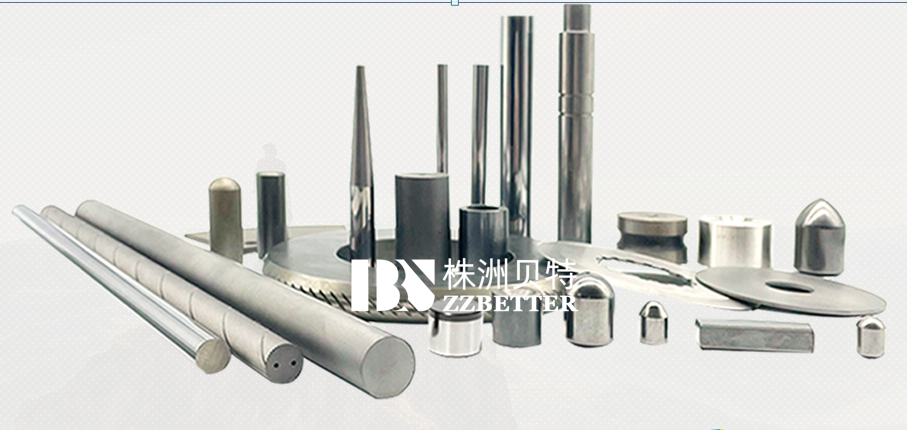

Ngaphandle kwamathuluzi okusika i-tungsten carbide nawo asetshenziselwa ukwenza izimayini, ukulinganisa, ukubumba, ukumelana nokugqoka, izinga lokushisa eliphezulu, njll.

Ikakhulukazi ngaphansi kwezimo ezifanayo, ijubane lokusika lamathuluzi we-tungsten carbide liphakeme izikhathi ezi-4 kuya kweziyi-7 kunelensimbi enesivinini esikhulu, futhi impilo iphakeme izikhathi ezi-5 kuye kwezingu-80.

Uma unentshisekelo emikhiqizweni ye-tungsten carbide futhi ufuna ulwazi olwengeziwe nemininingwane, UNGAXHUMANA NATHI ngocingo noma ngemeyili kwesokunxele, noma SITHUMELE I-IMEYILI ezansi nekhasi.