Ubuchwepheshe Bokukhiqiza Be-Hard Alloy

Ubuchwepheshe Bokukhiqiza Be-Hard Alloy

Ingxubevange eqinileluhlobo lwempahla eqinile eyakhiwe ngensimbi eqinile ephikisayo kanye nensimbi eboshiwe; ama-alloys aqinile, ayizinto eziqinile ezinokumelana nokugqoka okuphezulu nokuqina, okukhiqizwa yi-powder metallurgy; ngenxa yokusebenza kwayo okuhle kakhulu, i-carbide enosimende isetshenziswa kabanzi emishinini, izingxenye ezingagugi, izimayini, ukumba i-geological, izimayini zikawoyela, izingxenye zemishini neminye imikhakha.

I-Hard Metals Production Technology ibhekene nobuchwepheshe bokukhiqiza kanye nophenyo lwesakhiwo kanye nezakhiwo ezisebenza ngokomzimba zezinsimbi eziqinile. Esinye sezici ezibalulekile ekuqhubekeleni phambili kwezobuchwepheshe ukukhiqizwa kuzwelonke kwezinsimbi eziqinile. Ukuthuthukiswa kanye nokwethulwa kwezinsimbi eziqinile ezisebenza kahle kakhulu kuqinisekisa ukuthi ukukhiqizwa kwabasebenzi kuzokhula emsebenzini wensimbi, izimayini, uwoyela, kanye nezimboni zamalahle.

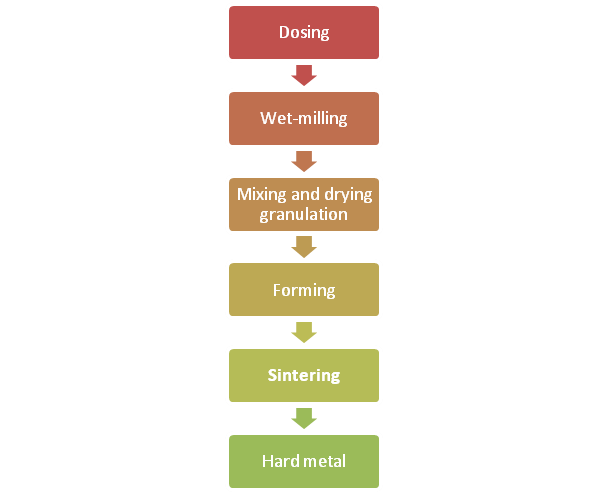

Inqubo yokukhiqiza ye-carbide enosimende imi kanje: ukulungiswa kwengxube, ukucindezela nokwenza, ukucwilisa. Kunezinqubo ezi-3 sezizonke.

Ishadi eligelezayo lenqubo yokukhiqiza ingxubevange eqinile

Izinto ezisetshenziswayo kanye nenani elincane lezithasiselo ezidingekayo ziyakalwa futhi zilayishwe emshinini wokugaywa webhola eligoqayo noma emshinini wokugaya ibhola elinyakazayo. Emshinini webhola, izinto zokusetshenziswa ziyacwengwa futhi zisakazwe ngokulinganayo. Ngemva kokumiswa kwesifutho kanye nokusefa kokudlidliza, ingxube enokwakheka okuthile kanye nezidingo zosayizi wezinhlayiyana zenziwa ukuze kuhlangatshezwane nezidingo zokucindezela ukwakha nokucwilisa. Ngemuva kokucindezela nokucwilisa, izikhala ze-alloy eziqinile ziyakhululwa futhi zipakishwe ngemuva kokuhlolwa kwekhwalithi.

Izikhala zensimbi eqinile

Indlela yokucubungula ye-carbide enosimende engaqinile:

1. Ukucutshungulwa kwentambo yangaphakathi nangaphandle: ukucutshungulwa kwentambo ye-carbide kufanele kucutshungulwe ngokugaya intambo, akukwazi ukucutshungulwa ngokuqondile ngompompi wesikulufa.

2. Ukucutshungulwa kwe-groove yangaphakathi: induku yokugaya idayimane kufanele ikhethwe, futhi inani lokusika isikhathi ngasinye lilawulwa libe ngu-20 kuya ku-30 um. Ukulungiswa okuqondile kufanele kwenziwe ngokuvumelana nezinzuzo kanye nokubi kwenduku yokugaya idayimane.

3. I-EDM

4. Welding processing: brazing, silver welding processing

5. Ukucutshungulwa kokugaya: ukugaya okungenasikhungo, ukugaya kwangaphakathi, ukugaya phezulu, ukugaya ithuluzi, isondo lokugaya ngokuvamile isondo lokugaya idayimane, ukukhetha okuqondile kuye ngezidingo zenqubo.

6. Ukucutshungulwa kwe-Laser: ukusika i-laser ukwakha, ukubhoboza kuyatholakala, kodwa ubukhulu bokusika buvinjelwa amandla emingcele yomshini we-laser.

Uma umkhiqizo wakho we-tungsten carbide uba buthuntu noma "uguqubele", awudingi ukuthenga isihlanzi sobucwebe esibizayo ukuze ukhanyise futhi upholise ubucwebe bakho be-tungsten. Ingxube elula yamanzi anensipho nendwangu ehlanzekile ukuphela kwezinto ozidingayo ukuze uhlanze le nsimbi eqinile, ekwazi ukumelana nokuklwebheka. Futhi, i-silicon carbide ingcono kakhulu ukulola i-carbide.

Uma unentshisekelo ngemikhiqizo ye-tungsten carbide futhi ufuna imininingwane eyengeziwe nemininingwane, ungaXHUMANA NATHIngocingo noma ngeposi kwesokunxele, nomaSITHUMELE IMEYILIekugcineni kwaleli khasi.