Yiziphi Izinzuzo ze-Tungsten Carbide ku-Tooling?

Yiziphi Izinzuzo ze-Tungsten Carbide ku-Tooling?

Njengoba sonke sazi, impahla ye-tungsten carbide ibizwa ngokuthi "amazinyo ezimboni". Inobunzima obukhulu kakhulu kanye nokuminyana okuphezulu, isetshenziswa kabanzi emikhakheni yokusika, ukubhoboza, nokuvikela ukugqokwa.

I-Wikipedia ichaza i-tungsten carbide kanje: “I-tungsten carbide (ifomula yamakhemikhali: WC) iyinhlanganisela yamakhemikhali (ikakhulukazi, i-carbide) equkethe izingxenye ezilinganayo ze-tungsten nama-athomu ekhabhoni. Ngendlela yayo eyisisekelo, i-tungsten carbide iyimpushana empunga ecolekile, kodwa ingacindezelwa futhi yakheke ibe yizimo ngokusebenzisa i-sintering ukuze isetshenziswe emishinini yezimboni, amathuluzi okusika, ama-abrasives, amagobolondo okubhoboza izikhali, nobucwebe. I-Tungsten carbide icishe iqine ngokuphindwe kabili kunensimbi, ne-Young's modulus ecishe ibe ngu-530–700 GPa, futhi iphinda kabili ukuminyana kwensimbi—cishe imaphakathi phakathi komthofu negolide. Iqhathaniswa ne-corundum (α-Al2O3) yokuqina futhi ingapholishwa futhi iqedwe kuphela ngama-abrasives okuqina okuphakeme njenge-cubic boron nitride ne-diamond powder, amasondo, nezinhlanganisela.”

I-Tungsten carbide impahla inokusebenza okuphezulu kakhulu. Yiziphi izinzuzo lapho kusetshenziswa impahla ye-tungsten carbide emkhakheni wamathuluzi?

1. Ukuqina okuphezulu. Ukuqina kwe-tungsten carbide kuyahlukahluka kusuka ku-83HRA kuya ku-94HRA. Ukuqina okuphezulu kwenza i-tungsten carbide igqoke izikhathi ezifika kweziyi-100 kunensimbi ezimeni ezihlanganisa ukuhuzuka, ukuguguleka, kanye nenyongo. Ukumelana nokugqokwa kwe-tungsten carbide kungcono kunezinsimbi zamathuluzi angakwazi ukugqokwa.

2. Ukumelana nokushisa kanye ne-oxidation. Ukukhiqiza i-tungsten carbide, impahla ye-carbide izoshiswa esithandweni ngokushisa okuphezulu okungaba ngu-1400 centigrade. Ama-Tungsten-base carbides enza kahle aze afike ku-1000°F endaweni ene-oxidizing kanye no-1500°F ezindaweni ezingafaki i-oxidizing.

3. Ukuzinza kweDimensional. I-Tungsten carbide ayishintshile isigaba ngesikhathi sokushisisa nokupholisa futhi igcina ukuqina kwayo unomphela. Akukho ukwelashwa okudingekile.

4. I-Surface Finishes. Ukuqedwa kwengxenye ye-as-sintered kuzoba ngamasentimitha angama-50 amancane. Ukugaya okungaphezulu, okuyisilinda noma kwangaphakathi ngesondo ledayimane kuzokhiqiza ama-intshi angu-18 micro noma okungcono futhi kungakhiqiza okuphansi okungamayintshi angu-4 kuya kwangu-8. Ukugxusha kwedayimane nokucija kungakhiqiza amayintshi amancanyana angu-2 futhi ngokupholishwa okuphansi njengo-1/2 intshi encane.

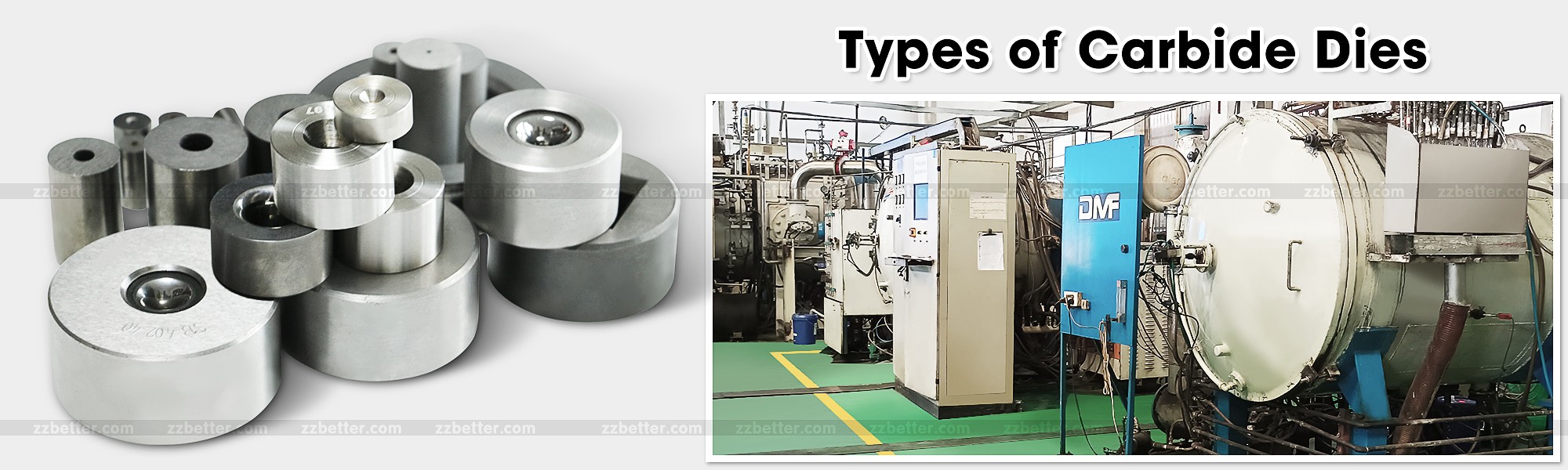

I-Zhuzhou Better Tungsten Carbide Company ingumhlinzeki we-tungsten carbide ochwepheshe. Isikhunta se-tungsten carbide ne-tungsten carbide dies singabanye abadayiswa kakhulu. I-ZZbetter ingakhiqiza isihloko esibandayo se-tungsten carbide siyafa, i-tungsten carbide hot forging dies, umdwebo we-tungsten carbide uyafa, futhi uzipho lwe-tungsten carbide luyafa. Ama-dies angenhla asetshenziswa kakhulu ezimbonini eziningi futhi ashintshwa ngensimbi ukuze abe yisinqumo esiphezulu sokusebenzisa amathuluzi. Ngobunzima obuphezulu, ukumelana nokugqoka okuphezulu, amandla okugoba aphezulu, nokusebenza okuzinzile emazingeni okushisa aphezulu naphansi, manje ukusetshenziswa kwe-tungsten carbide kubanzi kakhulu kunangaphambili. Inkampani yethu izoqhubeka nokuhlinzeka ngezixazululo zekhwalithi ephezulu ze-carbide kumakhasimende ethu kanye namakhasimende angaba khona ngethemba lokuthi i-carbide yethu ingabasiza ukuthi bafinyelele inani labo!

Uma unentshisekelo emikhiqizweni ye-tungsten carbide futhi ufuna ulwazi olwengeziwe nemininingwane, UNGATHI XHUMANA NATHI ngocingo noma ngemeyili kwesokunxele, noma SITHUMELE IMEYILI ezansi nekhasi.